Top Flite TOPA0150 User Manual

Page 41

❏

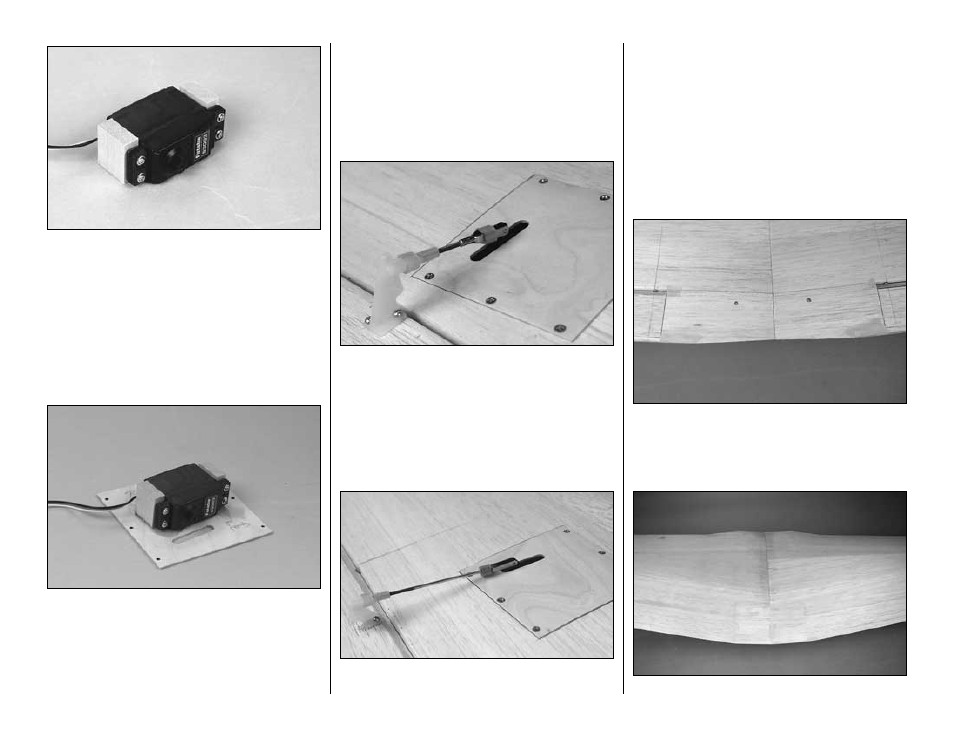

5. This will show the

right aileron, so refer to the

right aileron servo and hatch on the wing plan for the

correct orientation of the servo. Use the screws that

came with your servo to mount the aileron servo to

two 5/16" x 3/4" x 7/8" basswood

servo mount

blocks. There should be an approximately 1/32"

clearance between the blocks and the servo, and

between the servo and the hatch.

Hint: Use leftover

1/32" plywood or cardstock as shims under the servo

and between the servo and the blocks when drilling

the holes into the blocks.

❏

6. Use 30-minute epoxy to glue the servo mount

blocks to the

right aileron hatch. Make certain the

servo is positioned so the servo arm will be

centered and aligned with the slot in the hatch.

Note: The basswood servo mount blocks are porous

and rapidly absorb epoxy. After applying the first coat

of epoxy to the mount blocks, wait a few minutes and

apply an additional coat. You will see that in between

coats, most or all of the epoxy will have soaked in,

leaving little behind for gluing. Do this procedure a

few times until a thick coat of epoxy remains.

❏

7. Mount the left aileron servo and both flap

servos to the hatches the same way.

❏

8. Install a long servo arm on the right aileron

servo. Mount the right aileron hatch in the wing.

Connect the servo to the aileron with the hardware

shown on the plan. Add a few drops of thin CA to the

holes in the aileron and the horn mount plate for the

#2 x 3/8" screws.

❏

9. Connect the left aileron servo to the left aileron

the same way.

❏

10. Make the pushrods and connect the flap

servos to the flaps. Glue a small block of leftover

balsa inside the flap where the aft #2 x 3/8" screw

goes through the bottom flap skin. The same as the

elevators and rudder, use a T-pin to poke several

holes in the bottom flap skin where the flap control

horn mounts to the flap. Harden the area by adding

a few drops of thin CA to the holes. Allow the CA to

dry, then sand smooth. Note that the flap control

horn is mounted “backwards.”

Finish the wing

❏

1. Use leftover 1/16" balsa to sheet the bottom of

the center section of the wing between the flaps. Use

the holes in the wing bolt plate as a guide to cut

holes in the bottom sheeting.

❏

2. Sheet the top of the center section of the wing.

-41-