Top Flite TOPA0150 User Manual

Page 19

distances are not equal (if the stab is not level),

lightly trim the stab bases until you can get the stab

level.

Use caution not to change the incidence

angle of the stab. If the stab is not exactly level, but

it’s close, sometimes all it takes is shifting the weight

slightly.

Hint: Use balsa blocks of equal thickness to

level the stab. If you do this, make certain the stab is

fully contacting the stab bases.

❏

3. Stick a T-pin into the center fuse stringer above

F-1. Tie a small loop in one end of a 50" piece of non-

elastic line such as monofilament or Kevlar fishing

line. Slip the loop over the T-pin. Fold a piece of

masking tape over the string near the other end and

draw an arrow on it. Slide the tape along the string

and align the arrow with one end of the stab as

shown in the photo. Swing the string over to the

same position on the other side of the stab. Shift the

stab and slide the tape along the string until the

arrow aligns with both sides of the stab. The stab

must remain level and centered during this process.

❏

4. Mark the stab where it aligns with the fuse so it

can be realigned after you take it off.

❏

5. Remove the stab. Mix up a batch of 30-minute

epoxy. For additional strength, add Great Planes

Milled Fiberglass (GMR6165). Apply epoxy to the

stab bases and to the bottom of the stab where it

contacts the saddles. Reposition the stab and place

weights on top of it to hold it down. Confirm stab

alignment with the pin and string. Wipe away excess

epoxy and do not disturb the model until the epoxy

has fully hardened.

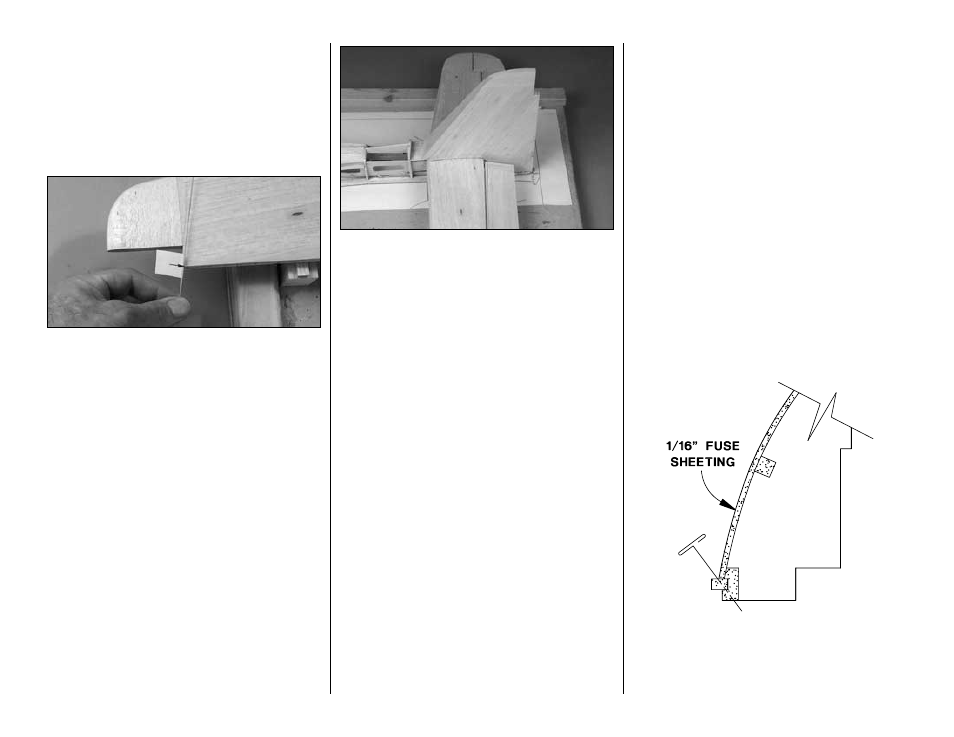

Refer to this photo for the following three steps.

❏

6. Use the “T-pin and straightedge” technique to

mark a centerline down the TE of the fin. After the

epoxy from the stab has fully hardened, test fit the fin

to the stab and fuse. Use a builder’s square placed

along the centerline you marked on the fin TE to

make sure the fin is vertical. Trim the fin sheeting

where necessary for a good fit to the top of the stab

and the sub stringers.

❏

7. Temporarily join the elevators to the stab with

the elevator joiner wire and the hinges. Cut round

notches in the fin sheeting to accommodate the

elevator joiner wire.

❏

8.

With the elevator joiner wire in position, glue

the fin into position with 30-minute epoxy. Before the

epoxy cures, make certain the fin is vertical and the

front of rib V-1 is centered on F-12. Do not build up a

fillet of epoxy between the fin sheeting and the stab.

Sheet the top of the fuse

By now you’ve noticed that the Focke-Wulf fuselage

has some interesting lines and curves. Unlike many

other warbirds that have either a round fuselage

(such as a Corsair) or a “slab-sided” fuselage (such

as a Mustang), the Focke-Wulf fuse features a

mixture of irregular curves and converging angles.

While this doesn’t necessarily make sheeting the

fuselage difficult, careful thought and planning were

required during the construction of our prototype to

determine a procedure that modelers could

duplicate. Blocks are used in areas where it would be

too difficult to sheet. If you are an expert at sheeting

models, or if you prefer to do it a different way, you

could venture off.

For most modelers, we

recommend that you carefully follow these

instructions to end up with a fuselage that replicates

the lines of the Focke-Wulf.

❏

1. One at a time, remove the T-pins from the main

stringer and reinsert them as shown in the sketch.

This way, the pins won’t be concealed under the

sheeting when it’s time to take the fuse off the

building board.

-19-