Top Flite TOPA0150 User Manual

Page 36

workbench. Measure the distance from the tip of the

other panel down to the workbench. The distance

should be 6-11/16", plus or minus 1/8", as measured

from the bottom main spar at rib 12. If necessary, make

adjustments so this measurement can be achieved.

❏

4. Once the correct dihedral has been confirmed,

and any other adjustments have been made for a

good fit, permanently join both wing panels with 30-

minute epoxy. Make certain the epoxy you are using

provides enough working time to join all the parts

and position your clamps. For the strongest bond,

coat all contacting surfaces with epoxy (both sides of

the spar web and the correct side of the forward wing

joiners). Make certain the root rib W-1 of the panels

are in alignment.

❏

5. Use fuelproof paint or epoxy thinned with

alcohol to coat and fuelproof the landing gear area.

If you prefer to do this at a later time, make sure it is

done

before the covering is applied, otherwise the

paint may soak through the top sheeting and blemish

iron-on coverings. You can use brush-on paint, but

you will have the most uniform coverage and the best

results if you apply the paint with an airbrush. Mix a

drop or two of blue to an ounce of yellow to get the

light shade of green resembling chromate green

used to protect aluminum in aircraft.

❏

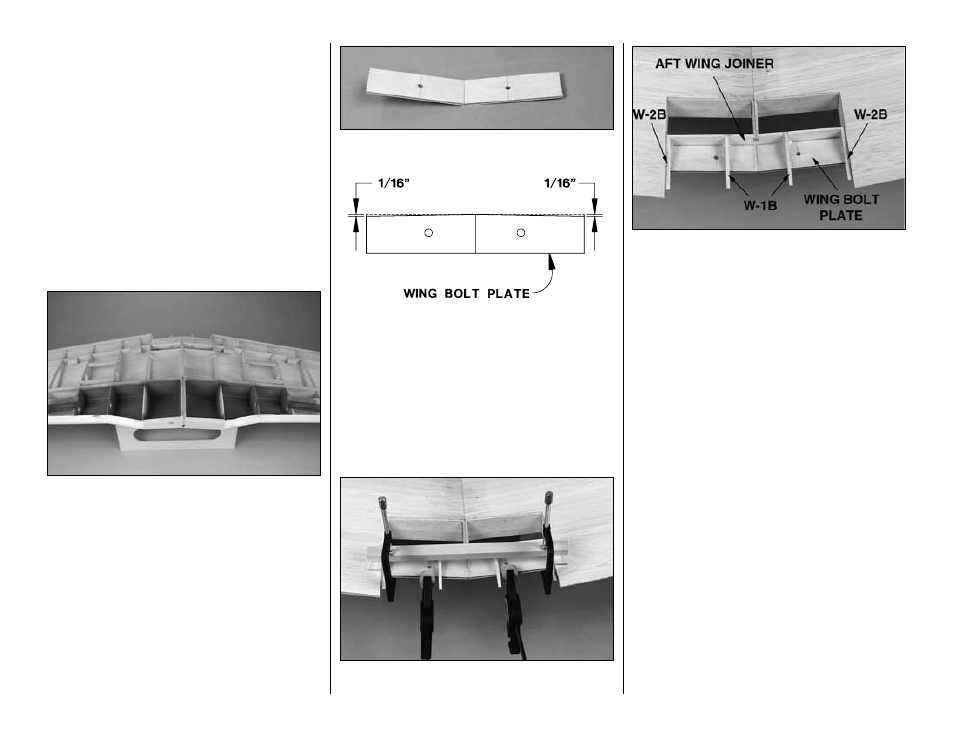

6. Test fit, then glue the die-cut 1/8" plywood

aft wing

joiner and the die-cut 1/8" plywood ribs W-2B to the

wing (these parts can be seen in following photos).

❏

7. Drill #7 (or 13/64") holes through the 1/8" x

1-1/4" x 7" plywood

wing bolt plate where shown on

the plan. Trim one edge of the wing bolt plate as

shown in the sketch. This will now be the front. Cut

partway through both sides of the center of the wing

bolt plate. Bend the wing bolt plate to the same angle

as the wing, trying not to break it. If you do, glue it

together at the same angle as the aft wing joiner.

This photo gives you an idea of how to clamp the

wing bolt plate into position.

❏

8. Test fit the wing bolt plate to the wing. Trim the

ends as necessary for a good fit. Use 30-minute

epoxy to glue the wing bolt plate to the aft wing

joiner. Glue ribs W-1B to the assembly.

Sheet the bottom of the wing

If you haven’t done so already, make four 6" x 30"

wing skins from eight 1/16" x 3" x 30" balsa sheets.

❏

1. Plan the routing of the aileron and flap servo

cords. They can be installed in the wing after the

model is finished, though some may prefer to do it

now. Cut a hole in rib 1 so the cords can be

connected inside the wing, then passed through a

hole cut in the top sheeting.

❏

2. With the wing upside-down on a stand or a

cradle, trim two of the 6" x 30" sheets to make the

forward skins for both sides of the bottom of the

wing. Do not glue the skins to the wing yet.

❏

3. Use the other two 6" x 30" balsa sheets to make

the aft skins. For now, cut the aft skins oversize to

allow for trimming and positioning after the forward

skins have been glued into position.

❏

4. Sand the skins flat, smooth and even.

-36-