Additional items req uired, Impor t ant b u ilding no tes – Top Flite TOPA0910 User Manual

Page 4

Ser

v

o

Extensions

(3)

Y

-har

ness (HCAM2751 f

o

r Futaba

®

)

(4) 6" [150mm] e

xtension (HCAM2701 f

or Futaba)

(2) 12" [300mm] e

xtension (HCAM2711 f

or Futaba)

(4) 24" [610mm] e

xtension (HCAM2721 f

or Futaba)

Batteries

1000 mAh NiCd batter

y f

or the receiv

e

r

500 mAh NiCd batter

y

f

or the lighting system

ENGINE RECOMMEND

A

TIONS

Engine

The recommended engine siz

e

f

or the Cessna 310 is

a .46-.50 tw

o-strok

e

.

This air

p

lane w

as e

xtensiv

ely

flo

wn on the O

.S

.

®

.46AX tw

o strok

e

engines and

Bisson m

uffler

.

Though y

our instincts might tell y

o

u

that a plane of this siz

e and w

eight will be

under

po

w

ered with these engines

, this is not tr

ue

.

Dur

ing our test flights w

e

used these engines f

o

r

taking off from g

rass and asphalt with no prob

lems

.

The climb out from tak

e

off w

as impressiv

e

.

Once the

plane w

as at altitude the plane w

as flo

wn at 1/2 to 3/4

throttle

.

As par

t of our testing the plane w

as flo

wn on

a single engine from both the r

ight and left nacelle

.

The O

.S

.

.46 w

as enough po

w

er to maintain flying

altitude

, fly a figure eight, and a rectangle approach to

the r

unw

a

y.

T

he air

plane has the po

w

e

r to fly on one

engine b

u

t not enough to climb out from a missed

landing approach.

The O

.S

..46 or .50 SX is the engine

of choice to k

eep e

v

er

ything hidden under the nacelle

.

Muffler

The Bisson Pitts Muffler (BISG4046) fits v

e

ry

w

ell in

the nacelle and is the recommended after mar

k

e

t

m

u

ffler f

or the Cessna 310.

OPTIONAL RETRA

CT

ABLE

LANDING GEAR

Robar

t Cessna 310 Retr

acts (R

OBQ1623)

Rob

a

rt

Standard Air Kit with v

a

riab

le

ra

te v

alv

e (R

OBQ2302)

10' [1meter] Pressure tubing (R

OBQ2369)

(2) Air line quic

k disconnects (R

OBQ2395)

ADDITIONAL ITEMS REQ

UIRED

ADHESIVES & B

UILDING SUPPLIES

This is the list of Adhesiv

es and Building Supplies

that are required to finish the Cessna 310.

❏

3' [900mm] standard silicone fuel

tubing (GPMQ4131)

❏

1/2 oz.

[15g]

Thin Pro

™

CA (GPMR6001)

❏

1 oz.

[30g] Medium Pro CA+ (GPMR6008)

❏

Pro 30-min

u

te epo

xy (GPMR6047)

❏

Pro 6-min

ute epo

xy (GPMR6045)

❏

Dr

ill bits:

1/16" [1.6mm], 5/64" [2mm], 3/32"

[2.4mm], 7/64" [2.8mm], 1/8" [3.2mm], 11/64"

[4.4mm]

❏

Silv

er solder w/flux (GPMR8070)

❏

#1 Hob

b

y

knif

e (HCAR0105)

❏

#11 b

lades (5-pac

k, HCAR0211)

❏

Medium

T

-pins (100, HCAR5150)

❏

Masking tape (T

OPR8018)

❏

Threadloc

k

e

r thread loc

k

ing cement (GPMR6060)

❏

Denatured alcohol (f

or epo

xy clean up)

❏

Hot melt glue and glue gun (a

v

ailab

le at hob

b

y,

cr

aft and hardw

are outlets)

OPTIONAL SUPPLIES &

T

OOLS

Here is a list of optional tools mentioned in the

man

ual that will help y

ou b

uild the Cessna 310.

❏

21st Centur

y

®

sealing iron (CO

VR2700)

❏

21st Centur

y iron co

v

er (CO

VR2702)

❏

4 oz.

[113g] aerosol CA activ

ator (GPMR634)

❏

CA applicator tips (HCAR3780)

❏

Epo

xy br

ushes (6, GPMR8060)

❏

Mixing stic

ks (50, GPMR8055)

❏

Mixing cups (GPMR8056)

❏

Hob

bico Duster

™

compressed air (HCAR5500)

❏

Rotar

y tool such as Dremel

®

❏

Rotar

y tool reinf

orced cut-off wheel (GPMR8020)

❏

Ser

v

o

hor

n dr

ill (HCAR0698)

❏

Dead Center

™

Engine Mount Hole

Locator (GPMR8130)

❏

AccuThro

w

™

Deflection Gauge (GPMR2405)

❏

CG Machine

™

(GPMR2400)

❏

Precision Magnetic Prop Balancer (T

OPQ5700)

IMPOR

T

ANT B

U

ILDING NO

TES

•

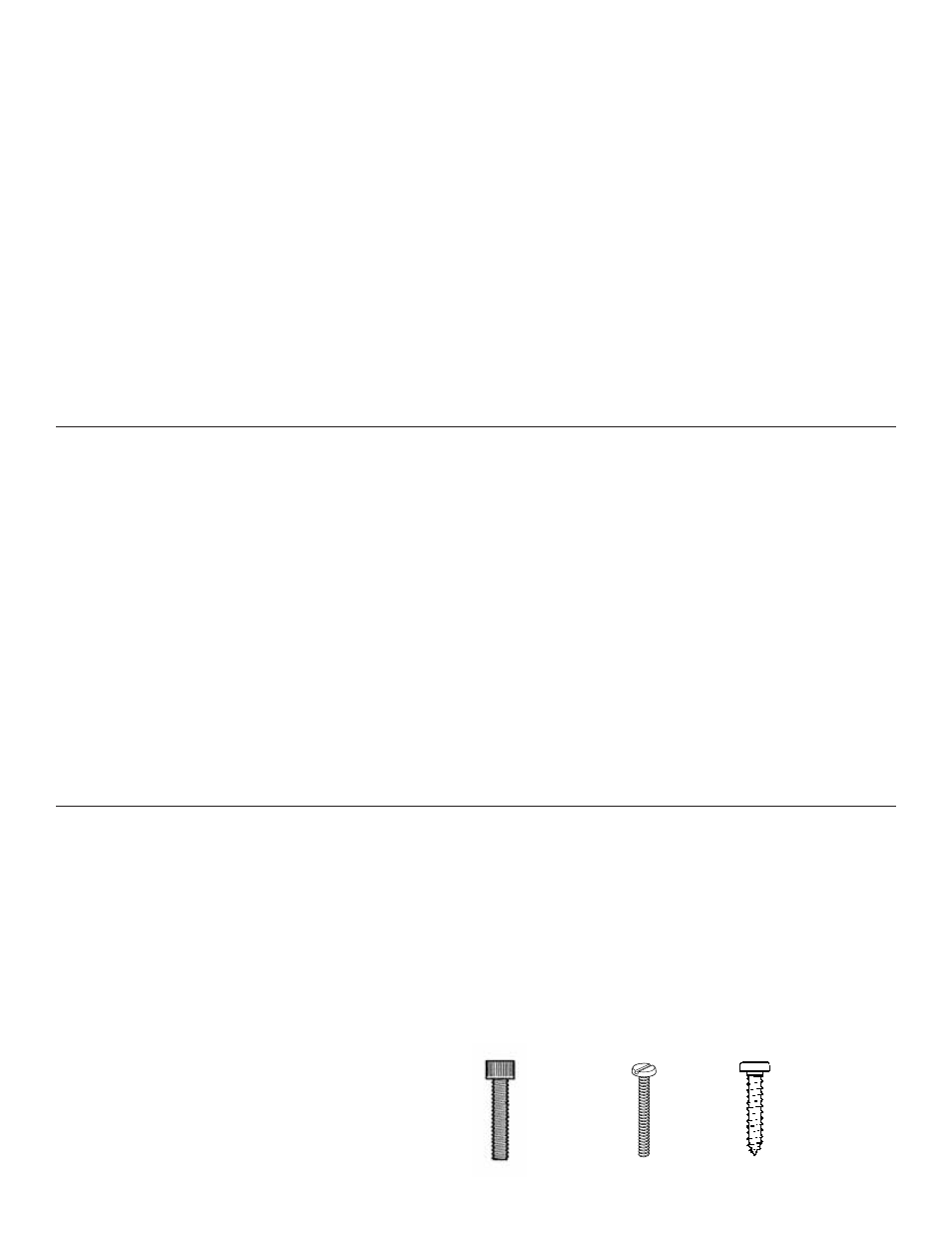

There are tw

o types of scre

ws used in this kit:

Sheet metal scre

ws

are designated b

y

a n

umber

and a length.

F

or e

xample #6 x 3/4" [19mm]

This is a n

umber six scre

w that is

3/4" [19mm] long.

Mac

hine scre

ws

are designated b

y

a n

umber

, threads

per inch, and a length.

F

o

r e

x

ample 4-40 x 3/4" [19mm]

This is a n

u

mber f

our scre

w

that

is 3/4" [19mm] long with f

o

rty

threads per inch.

Soc

ket head cap scre

ws

are designated b

y

a

n

umber

,

threads per inc

h

and a length.

F

or e

xample

4-40 x 3/4" [19mm]

This is a n

u

mber f

our scre

w

that

is 3/4" [19mm]

long with f

o

rty

threads per inch

.

•

When y

ou see the ter

m

test fit in the instr

uctions

, it

means that y

ou should first position the par

t on the

assemb

ly without using an

y glue

, and then slightly

modify or custom fit the par

t as necessar

y f

or the

best fit.

•

Whene

ve

r the ter

m

glue is wr

itten y

ou should rely upon

your e

xper

ience to decide what type of glue to use

.

When a specific type of adhesiv

e w

o

rks best f

or that

step

, the instr

uctions will mak

e

a recommendation.

•

Whene

v

er just epo

xy is specified y

ou ma

y use

either 30-min

ute (or 45-min

ute) epo

xy or 6-min

ute

epo

xy

.

When 30-min

u

te epo

xy is specified it is

highly recommended that y

ou use only 30-min

ute

(or 45-min

ute) epo

xy

, because y

ou will need the

w

o

rking time and/or the additional strength.

•

Photos and sk

etches are placed bef

ore the step the

y

ref

er to

.

F

requently y

ou can study photos in f

o

llo

wing

steps to get another vie

w

of the same par

ts

.

- 4

-