Top Flite TOPA0910 User Manual

Page 10

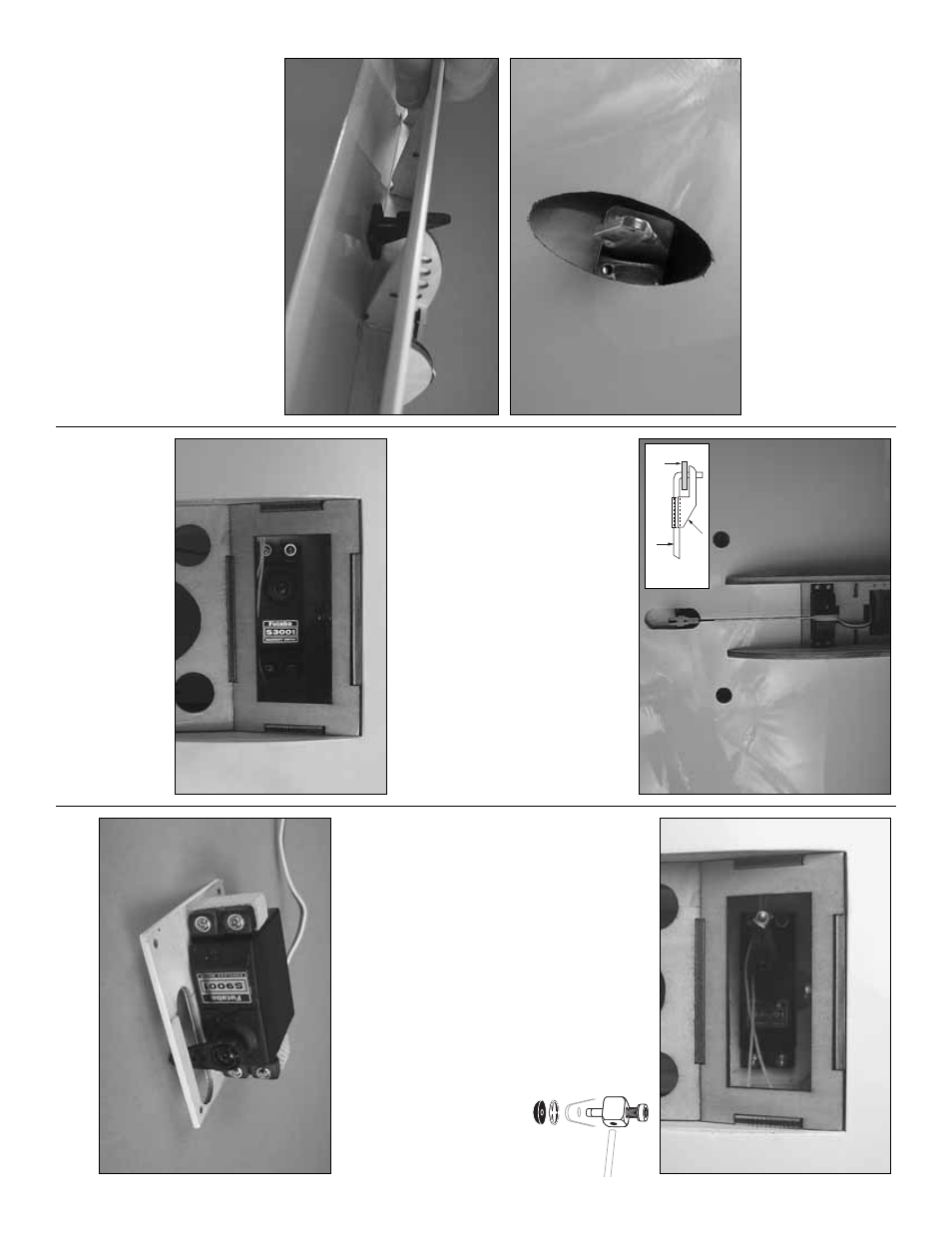

into the holes to harden the threads

.Once the glue has

cured re-install the ser

vo

mounting scre

ws

.

Be sure the

ser

vo

lead comes up through the slot alongside of the

ser

vo

.

When installing the flap ser

vo

in the r

ight wing

panel, the ser

vo ar

m should be pointed to

w

ards the

wing tip

.

When installing the ser

vo

in the left wing, the

ar

m should be pointed to

w

a

rds the wing center

.

❏❏

2.

Center a b

lac

k control hor

n in the opening

abo

ve the flap

, positioning it as sho

wn (the control hor

n

should be bac

kw

ards from what w

ould be considered

the nor

mal direction of a control hor

n.) Dr

ill a 1/16"

[1.6mm] hole through each of the mounting holes in the

control hor

n and into the plyw

ood plate in the flap

.

D

rill

only through the plyw

ood plate

.

DO NO

T

dr

ill through

the flap

.

Inser

t and remo

ve

a #2 x 3/8" [10mm] scre

w

into each of the holes

.

Apply a couple drops of thin CA

into the holes to harden the threads

.Once the glue has

cured attach the hor

n

to the flap with f

our

#2 x 3/8" [10mm] scre

ws

.

❏❏

3.

Scre

w

a n

ylon cle

vis onto a .074 x 6" [152mm]

threaded wire 20 tur

n

s

.

Slide a n

ylon cle

vis retainer

onto the cle

vis

.

Install the cle

vis into the outer

most

hole of the control hor

n.

Then slide the silicone

retainer o

v

er the cle

vis

.

D

rill a 5/64" [2mm] hole in the

outer hole of the ser

v

o

ar

m.

P

osition the ser

v

o

ar

m as

sho

wn and be sure the flap is fully closed.

With a fine

tip mar

k

er

, mar

k the wire where it aligns with the outer

hole of the ser

v

o

ar

m.

Mak

e a 90 deg

ree bend on the

mar

k.

Cut the wire so the wire is 3/8" [10mm] in length

after the bend.

Inser

t the wire into the ser

v

o

ar

m and

loc

k it in place with a n

y

lon F

aslink.

❏❏

4.

Install the throttle ser

vo

into the ser

vo

opening.

(Note that the ser

vo

is mounted on the bottom of the

nacelle).

Inser

t and remo

ve

a ser

vo

mounting scre

w into

each of the pre-dr

illed holes

.Apply a couple drops of thin

CA into the holes to harden the threads

.

Once the glue

has cured, re-install the ser

vo

mounting scre

ws

.

❏❏

5.

Install a br

ass scre

w loc

k

connector

, n

y

lon retainer r

ing and a

4-40 x 1/4" [6mm] soc

k

et head cap

scre

w onto the ser

v

o

ar

m.

Then

center the ser

v

o

and install the ar

m

onto the ser

v

o

.

❏❏

6.

Install a 6" [152mm] ser

v

o

e

xtension onto the

throttle and flap ser

v

o

leads

.

Secure the e

xtension to

the lead with tape

, a piece of shr

ink tube or some

other method to k

eep them from coming unplugged.

❏❏

7.

Install a 24" [610mm] ser

v

o

e

xtension onto

the aileron ser

v

o

lead.

Secure the e

xtension to the

lead with tape

, a piece of shr

ink tube or some other

method to k

eep them from coming unplugged.

❏❏

8.

Install the aileron ser

v

o

betw

een the w

ooden

ra

ils under the

ailer

on ser

v

o

co

ver

using the

- 10

-

FA

S

LINK

2-56 (.074")

PU

S

HR

OD WIRE

S

ER

V

O

HORN