Additional items required – Top Flite TOPA0704 User Manual

Page 4

4

ENGINE RECOMMENDATIONS

The recommended engine size range for the Corsair is

3.0 – 4.0 cu in [50 – 55cc] two-stroke gasoline engine.

All of our testing was completed with the DLE 55

(DLEG0055) and the J’TEC Pitts Style Wraparound

Muffl er (JTCG1035). Another good choice would be

the O.S. GT55 (OSMG1555). Remember that this is a

scale model that is intended to fl y at scale-like speeds,

so throttle management should be practiced.

NOTE:

Instructions for mounting every possible engine

cannot be incorporated into this manual. Modelers using

other engines should refer to this instruction manual

as a guide for mounting their engine in a similar way.

RETRACTABLE LANDING GEAR

The Top Flite Giant Corsair ARF requires the use of

retractable landing gear. This model is designed for

Robart pneumatic retracts. Following is the complete

list of items required to install the Robart retracts:

❍ Robart Main Gear for the Top Flite Giant F4U

Corsair (ROBQ1655)

❍ Robart Fork Pneumatic Retract Tail Wheel

(ROBQ2230)

❍ Robart Large Scale Deluxe Air Control Kit

(ROBQ2305)

❍ Robart High Pressure Air Tubing 10' (ROBQ2369)

NOTE:

An air pump will also be required to pressurize

the air tank. The Robart hand pump could be used but

is not practical because of the large capacity of the

air tank in this model. A small, 12V electric pump is

recommended and can be purchased at an automotive

or hardware store.

ADDITIONAL LANDING GEAR OPTION

Just as we were putting this manual together Robart

introduced a new electric retract option. This will drop

into the same opening as the pneumatic landing

gear. For more information on these turn to page 46

of this manual.

ADDITIONAL ITEMS REQUIRED

REQUIRED HARDWARE & ACCESSORIES

This is the list of hardware and accessories required

to finish the Corsair.

Order numbers are provided

in parentheses.

❍ R/C foam rubber (1/4" [6mm] - HCAQ1000, or 1/2"

[13mm] - HCAQ1050)

❍ 1" [25mm] Servo Arm

(FUTM2120 for Futaba servos)

❍ 3' [900mm] gasoline fuel tubing (GPMQ4135)

❍ 1 oz. [30g] Thin Pro

™

CA (GPMR6002)

❍ 1 oz. [30g] Medium Pro CA+ (GPMR6008)

❍ Pro 30-minute epoxy (GPMR6047)

❍ Pro 6-minute epoxy (GPMR6045)

❍ Silver solder w/fl ux (STAR2000)

❍ Hobbico

®

Soldering Iron 60 Watt (HCAR0776)

❍ #1 Hobby knife (HCAR0105)

❍ #11 blades (5-pack, HCAR0211)

❍ R/C-56 canopy glue (JOZR5007)

❍ Epoxy brushes (6, GPMR8060)

❍ Mixing sticks (50, GPMR8055)

❍ Mixing cups (GPMR8056)

❍ Masking tape (TOPR8018)

❍ Threadlocker thread locking cement (GPMR6060)

❍ Denatured alcohol (for epoxy clean up)

❍ Panel Line Pen (TOPQ2510)

❍ Rotary tool such as Dremel

®

❍ Rotary tool reinforced cut-off wheel (GPMR8200)

❍ Drill bits: 1/16" [1.6mm], 1/8" [3.2mm], 5/32" 4mm,

5/64" [2mm], 3/32" [2.4mm], 7/64" [2.8mm}, 3/16"

[4.8mm, 1/4" [6.4mm].

OPTIONAL SUPPLIES AND TOOLS

Here is a list of optional tools mentioned in the manual

that will help you build the Corsair.

❍ 21

st

Century

®

sealing iron (COVR2700)

❍ 21

st

Century iron cover (COVR2702)

❍ 2 oz. [57g] spray CA activator (GPMR6035)

❍ 4 oz. [113g] aerosol CA activator (GPMR634)

❍ Epoxy brushes (6, GPMR8060)

❍ Mixing sticks (50, GPMR8055)

❍ Mixing cups (GPMR8056)

❍ Denatured alcohol (for epoxy clean up)

❍ Panel Line Pen (TOPQ2510)

❍ Rotary tool such as Dremel

❍ Rotary tool reinforced cut-off wheel (GPMR8200

IMPORTANT BUILDING NOTES

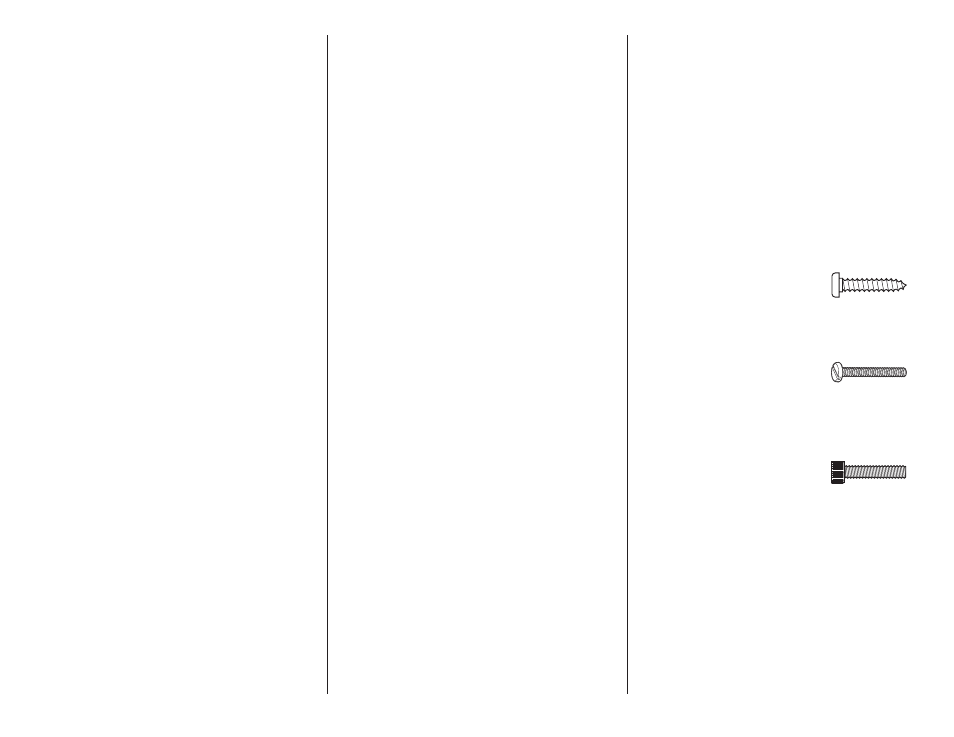

● There are three types of screws used in this kit:

Sheet Metal Screws

are designated by a number

and a length. For example #6

3/4" [19mm].

This is a number six screw

that is 3/4" [19mm] long.

Machine Screws

are designated by a number,

threads per inch,

and a length. For example

4-40

3/4" [19mm].

This is a number four screw

that is 3/4" [19mm] long with

forty threads per inch.

Socket Head Cap Screws

(SHCS)

are designated

by a number,

threads per inch

, and a length. For

example 4-40

3/4" [19mm].

This is a 4-40 SHCS that is

3/4" [19mm]

long with forty

threads per inch

● When you see the term

test fi t

in the instructions,

it means that you should fi rst position the part on

the assembly

without using any glue

, then slightly

modify or

custom fi t

the part as necessary for the

best fi t.

● Whenever the term

glue

is written you should rely

upon your experience to decide what type of glue to

use. When a specifi c type of adhesive works best for

that step, the instructions will make a recommendation.

● Whenever just

epoxy

is specifi ed you may use

either

30-minute (or 45-minute) epoxy

or

6-minute

epoxy. When 30-minute epoxy is specifi ed it is