Did you know – Top Flite TOPA0704 User Manual

Page 15

15

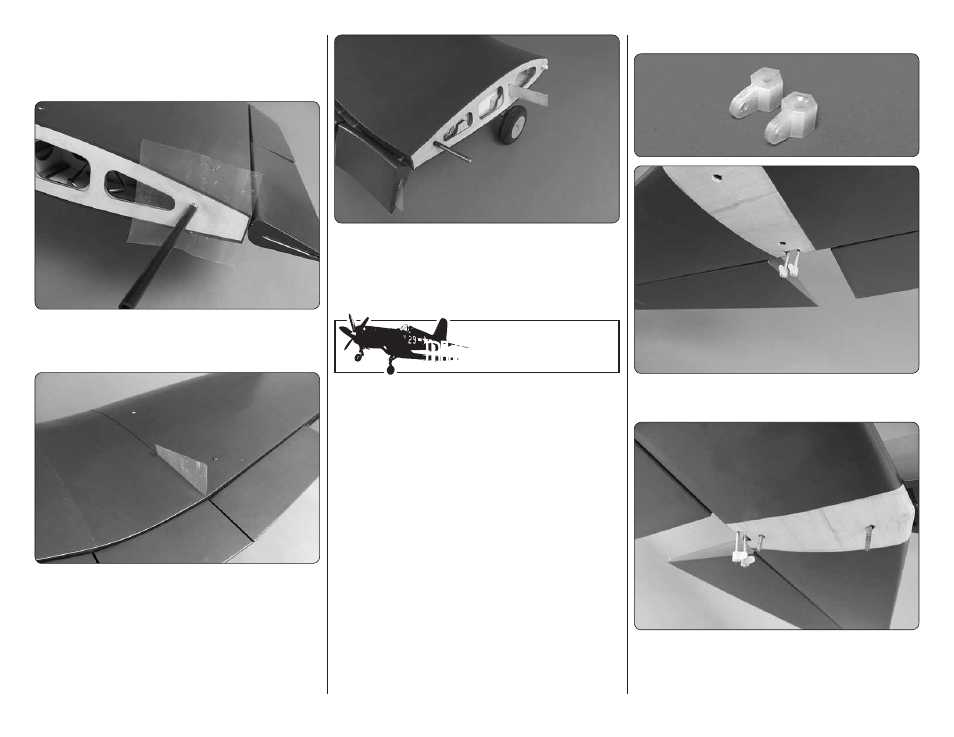

to align the fl ap on the outer wing panel with the fl ap

tab extending from the fl ap in the wing center section.

Once you are satisfi ed with the fi t of the wing and center

section remove the outer wing panel.

❏

❏

12. Cut a 3"

3" [76 mm

76 mm] square from

a plastic bag. Make a small hole in the center of the

plastic and slide it over the carbon tube.

❏

❏

13. Apply a light coating of epoxy to the carbon

tube. Install the outer wing to the wing center section.

As you slide the tube into the wing center section clear

away any excess epoxy. Repeat this until the wing panels

are pushed tightly together. Once the wings are together

tighten the 4-40

3/4" [19 mm] socket head cap screw

in the forward hole in the top of the wing to keep the

wings securely together while the epoxy hardens.

❏

❏

14. Once the glue has hardened remove both of

the wing bolts. Then, slide the outer wing panel from

the wing center section.

❏

15. Repeat steps 1-14 for the left wing panel.

Did You Know?…

Did You Know?…

According to old stories, the Japanese learned to

call the F4U “Whistling Death” because of the high-

pitched sound it made, though such a melodramatic

name sounds suspiciously like an invention of

American publicists. It was also known as the

“Bent Wing Bird”, though on the other side of the

coin this name sounds more like something out

of company press releases. Whatever the enemy

or the aircrew actually called the F4U, it was still a

machine to be reckoned with, one way or another.

Many pilots became aces in the Corsair, but even

its most passionate advocates admitted that it was

a handful.

ASSEMBLE THE FUSELAGE

Note: Just a reminder, whenever a screw is threaded

into wood sheeting or wood blocks we recommend that

you install the screw and then remove it. Apply a drop of

thin CA glue into the hole to harden the threads. After

the glue has hardened, re-install the screw.

INSTALL THE RUDDER & STAB / ELEVATOR

❏

1. Install the threaded nylon control horn onto the

threaded end of the elevator control wires.

❏

2. This next step can be a bit tedious so plan to take

your time. Install a 6-32

1-1/2" [38 mm] socket head

cap screw into the two holes in the fi berglass fairing

on top of the elevator passing through and exiting from