Top Flite TOPA0704 User Manual

Page 32

32

❏

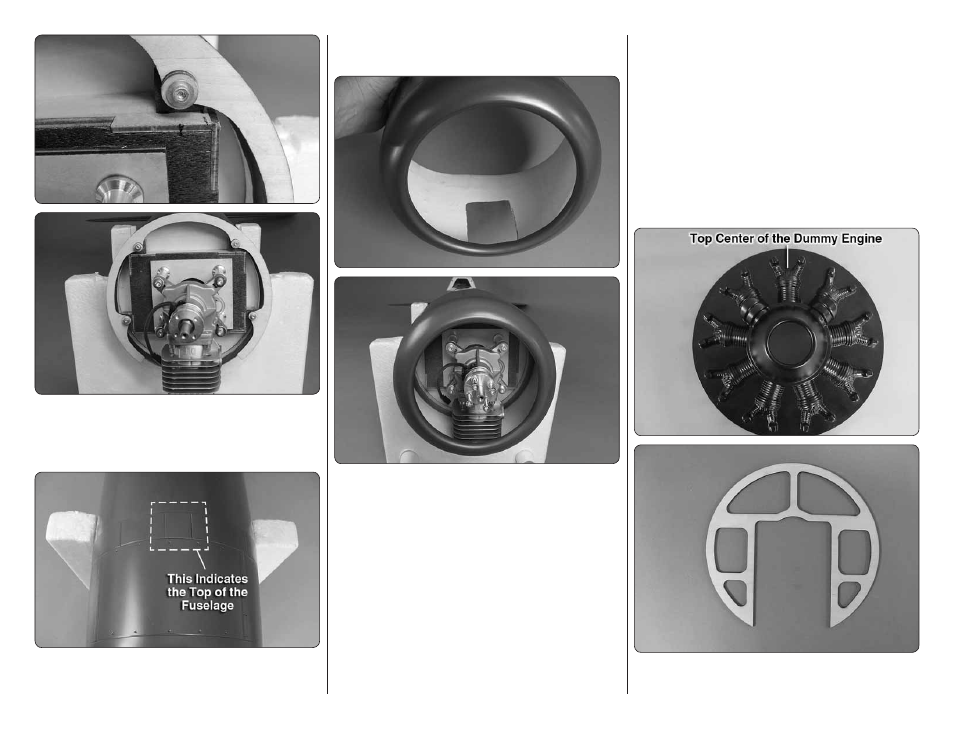

16. Apply glue to the back of the ring. Install the bolt

back into the cowl ring. Tighten the bolt so the ring

tightens against the cowl ring, gluing the ring to the

cowl ring. Do this for all four rings.

❏

17. Position the cowl on the cowl ring so that the

small cowl fl ap is centered on the fuselage.

❏

18. With a fi ne tip felt marker trace the outline of the

cylinder head onto the inside of the cowl.

❏

19. Use a high speed rotary tool or sharp knife to

roughly cut out the area you marked. Removing this area

will provide the needed clearance to fi t the cowl to the

cowl ring. After you have removed this section of the

cowl install the cowl back onto the fuselage. You should

now have enough clearance around the cylinder head

to allow you to position the cowl so the engine shaft

is centered in the cowl. Where the cowl ring contacts

the cowl, lightly sand the cowl and clean the area with

alcohol. Position the cowl back on the cowl ring. Once

you have the cowl centered properly, carefully reach

into the front of the cowl and apply a small amount of

medium CA glue to the cowl ring to tack glue the ring

to the cowl. A micro tip on the end of the glue bottle will

help to make the process of tack gluing the cowl easier.

Use CA accelerator to quickly harden the glue. After the

glue has hardened remove the cowl from the fuselage.

A note about the cowl mounting screws.

You have

probably already noticed that with the silicone tubing

sandwiched between the plywood rings, the socket head

cap screws remain in place with the cowl ring. This will

be important and a great help to you when you mount

the cowl to the front of the fuselage once the dummy

engine is in place. For the rest of the cowl installation you

should always have the cowl mounting screws retained

in the cowl ring with approximately 1/2" [13mm] of the

threads sticking out from the back of the cowl ring.

❏

20. Locate the plastic dummy engine and the plywood

dummy engine former.