Common abbreviations, Types of wood, Get ready to build – Top Flite TOPA0500 User Manual

Page 9: Build the tail surfaces, Metric conversion

• Photos and sketches are placed ahead of the step

they refer to. Frequently you can study photos in

following steps to get another view of the same parts.

COMMON ABBREVIATIONS

Deg = degrees

Elev = elevator

Fuse = fuselage

" = inches

LE = leading edge

Ply = plywood

Stab = stabilizer

TE = trailing edge

LG = landing gear

mm = millimeters

TYPES OF WOOD

BALSA BASSWOOD PLYWOOD

GET READY TO BUILD

1. Unroll the plan sheets. Roll them inside out so they lie

flat. Cut the left fuselage plan where indicated along the

dashed line and tape it to the right fuse plan

where indicated.

2. Remove all the parts from the box. Use a ballpoint pen

(not a felt tip pen) to lightly write the name or size on each

piece so you can identify it later. Use the

die-cut patterns

on pages 6 & 7 to identify and mark the die-cut parts

before you remove them from their die sheets. Many of

the parts already have numbers stamped on them, but in

some cases the number is located alongside the parts or

only on the die drawings on pages 6 and 7. You may

remove all the die-cut parts from their die sheets now or

wait until you need them. If a part is difficult to remove,

don’t force it out but cut around it with a #11 blade. After

you remove the parts from their die sheets, lightly sand

the edges to remove slivers or die-cutting irregularities.

Save some of the larger scraps of wood.

3. Separate the parts into groups such as stab, fin,

wing, and fuse. Store smaller parts in zipper-top food

storage bags.

BUILD THE TAIL SURFACES

MAKE THE STAB & FIN SKINS

❏

1. Use the

Hot Tip

that follows or your own method

to glue two 1/16" x 3" x 30" balsa sheets together to

make a 1/16" x 6" x 30" sheet for one of the stab skins.

❏

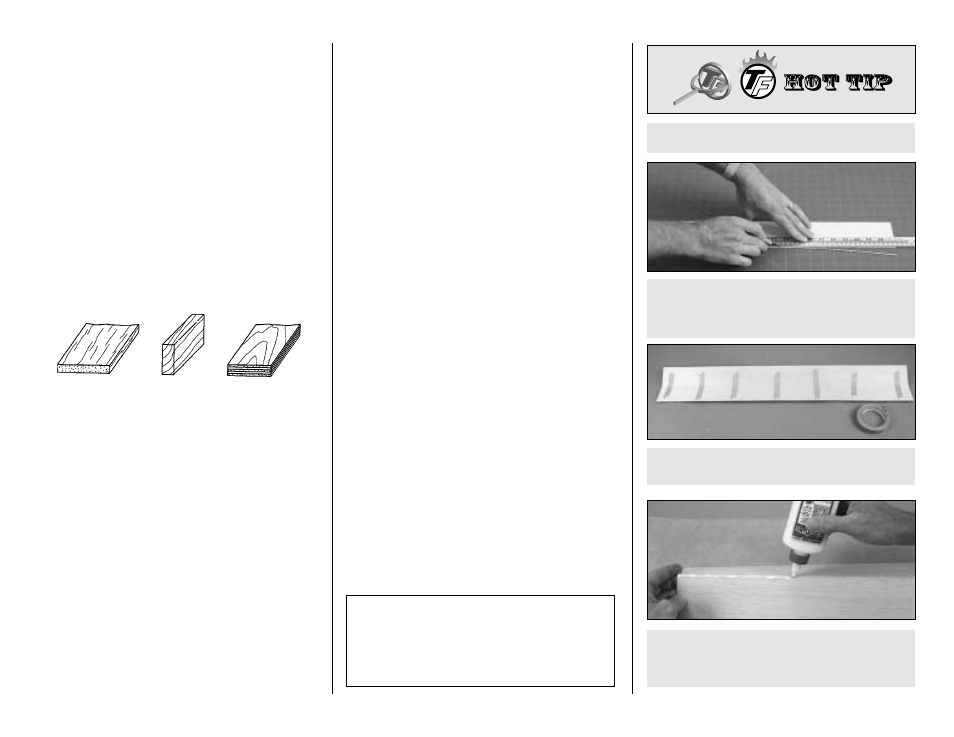

C. Place a sheet of Plan Protector or wax paper on

your workbench. Turn the taped together sheets over

and apply aliphatic resin (wood workers glue such as

Great Planes Pro) to the seams.

❏

B. Tightly tape the trued edges of the sheets together

with masking tape.

❏

A. Use a straightedge and a sharp #11 blade to

true one edge of both sheets. Do not cut all the way

through the first time but make several passes with

your knife to prevent the wood from splitting.

HOW TO MAKE THE STAB SKINS

Top Flite selects balsa that is intended for sheeting,

though occasionally a few of these sheets may have

a small nick or split near the ends. If your kit contains

a few of these sheets, arrange them and glue them

together so the defects will not interfere with the final

shape of the skin.

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

15" = 381mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762mm

36" = 914.4mm

METRIC CONVERSION

1" = 25.4mm (conversion factor)

- 9 -