Build the fin and rudder, Build the non-scale fin and rudder – Top Flite TOPA0500 User Manual

Page 14

❏

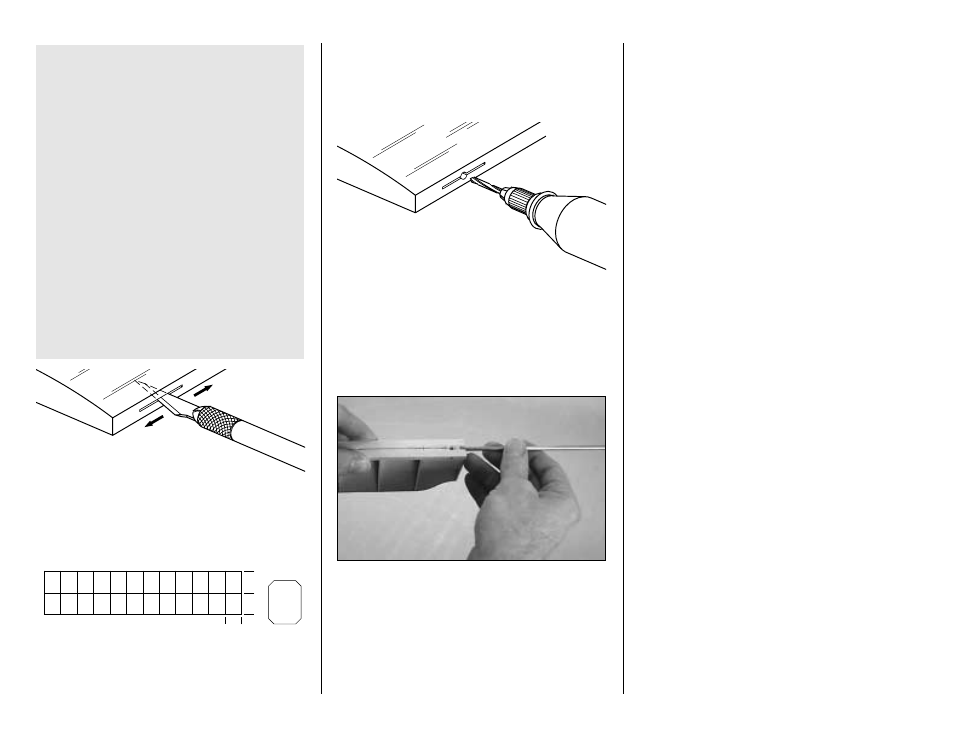

12. Mark the location of the hinge slots on the

elevators and stab where shown on the plan. With a #11

blade, cut the hinge slots in the elevators and the stab

along the centerlines you marked earlier

❏

13. Using the sketch above, cut six hinges from the

CA hinge strip supplied with this kit. Snip the corners

off so they go into the slots easier. You may cut all the

hinges now, or cut them as you need them.

❏

14. Test fit the hinges into the slots. If the hinges do

not slide into the slots easily, work your knife blade back

and forth in the slot a few times to provide more

clearance (it is really the back edge of the blade that

does the work here in widening the slot).

❏

15. Drill a 3/32" hole, 1/2" deep in the center of the

hinge slots. Use a rotary tool with a 3/32" drill bit or a

carbide cutter for the best results. Reinsert your knife

blade to

clean out

the slot after you drill the holes.

❏

16. Test fit the elevators to the stab with the hinges. If

any hinge slots are not wide enough or are misaligned,

make adjustments so the elevators accurately fit the stab.

❏

17. Drill a 9/64" (or 1/8") hole at the marks you made

on the centerline of both elevator leading edges for the

joiner wire. Cut a groove in the leading edge of both

elevators to accommodate the joiner wire.

Hint: Use a 5/32" brass tube sharpened at one end to

cut the grooves.

❏

18. Bevel the leading edges of the elevators to a “V” as

shown on the cross section of the plan. Use the centerline

on the elevator leading edges as a guide. Test fit the

elevators to the stab with the joiner wire and the hinges.

Note that the horn on the joiner wire points downward.

Cut a small notch in the TE of the stab for the horn on the

joiner wire. If necessary, remove the joiner and

tweak

it so

both elevators are in the same plane.

❏

19. Once more, test fit the elevators to the stab with

the hinges and the joiner wire. Make sure you can obtain

the control throws indicated on page 62 of the manual. If

you cannot, increase the “V” on the leading edge of

the elevators.

Set the stab and elevators aside.

BUILD THE FIN AND RUDDER

Now it’s time to decide which fin and rudder to build.

The non-scale fin and rudder is easier to build than the

scale fin and rudder while retaining the distinctive DC-3

outline. However, the scale fin and rudder utilize the

offset rudder hinge and balance tab. If you go for the

scale fin and rudder, we guarantee you’ll sit back and

grin as you watch others study the offset fin and rudder

on your DC-3 and admire your craftsmanship.

If you are going to build the non-scale fin and

rudder, proceed with the instructions that follow. If

you are going to build the scale fin and rudder, skip

to “Build the scale fin and rudder” on page 16.

Build the non-scale fin and rudder

❏

1. Cut the fin and rudder plan from the fuse plan along

the dashed line and tape it to your building board. Cover

the plan with Plan Protector.

❏

2. Apply medium CA to the embossed cutlines near the

trailing edge of the die-cut 1/16" fin ribs V1 through V7.

DRILL A 3/32" HOLE

1/2" DEEP, IN CENTER

OF HINGE SLOT

1"

1"

3/4"

AND #11 BLADE

WITH HOBBY KNIFE

CUT HINGE SLOT

IMPORTANT NOTES ABOUT CA HINGES

This kit is supplied with a CA hinge material

consisting of a 3-layer lamination of Mylar and

polyester. It is specially made for hinging model

airplane control surfaces. When properly installed,

this type of CA hinge provides the best combination

of strength, durability and easy installation. We trust

all of our Gold Edition war birds to these hinges, but

it is essential to install them correctly. Carefully

follow the hinging instructions in this manual for the

best result.

The most common mistake made by modelers

when installing CA hinges is making the hinge slots

too tight restricting the flow of CA to the back of the

hinges; or not using enough glue to fully secure the

hinge over its entire surface area. This results in

hinges that are only

tack glued

into the hinge slots.

The techniques for cutting the hinge slots and

gluing in CA hinges (near the end of the manual)

have been developed to ensure thorough and

secure gluing.

- 14 -