Fact, Dc-3 – Top Flite TOPA0500 User Manual

Page 13

not directly on top of the line. Use a square to make sure

you glue the LE perpendicular to the elevator core.

Hint: Place a 1/4" piece of balsa under the square to

raise it to the level of the LE.

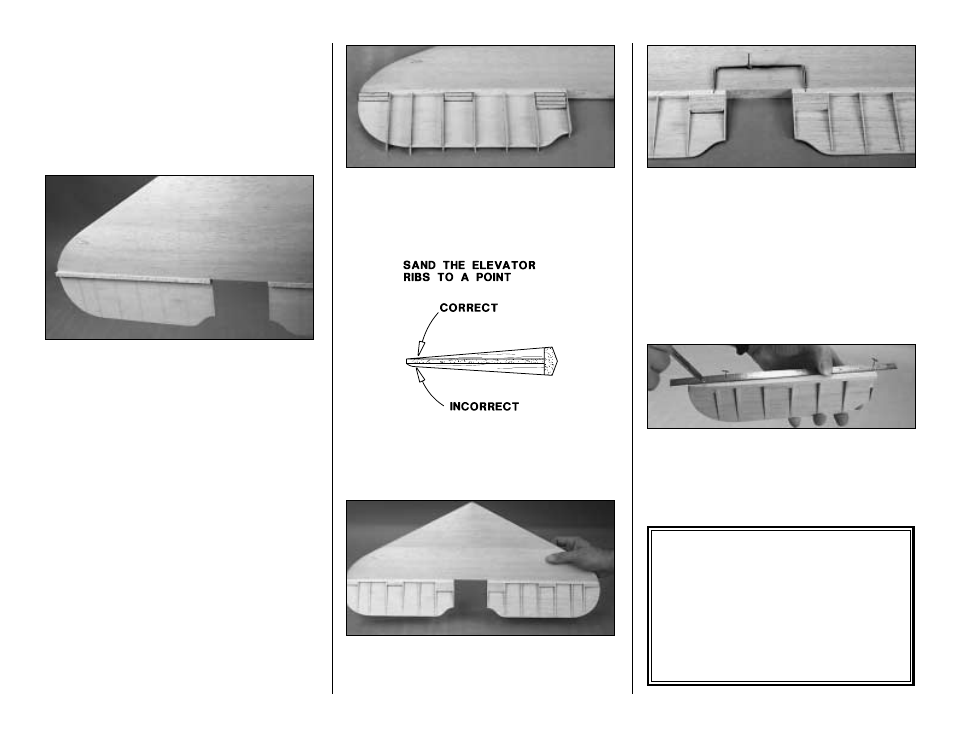

❏

3. Prepare the other elevator the same way.

❏

4. Apply about four small drops of medium CA, evenly

spaced, along the LE of one of the elevators and tack

glue it to the stab. When in place, the root end of the

elevator LE should be 1/16" beyond the mark you made

on the TE of the stab to accommodate the elevator root

cap ribs (refer to the plan). The elevator LE should also

be centered vertically on the stab TE. Practice alignment

before you tack glue the elevator. Tack glue the other

elevator to the other side of the stab the same way.

❏

5. Use a razor plane or your bar sander to shape the

leading edge of the elevators to match the stab.

❏

6. Use four 1/16" x 5/16" x 24" balsa sticks to make the

elevator ribs, and a piece of leftover 1/16" sheeting to

make the elevator root cap ribs (refer to the plan) for the

root end of the elevators. If you’ve decided to make the

scale location elevator ribs, use leftover 1/16" balsa

sheeting to make the additional ribs. Cut the sticks to the

correct length, then glue them to the elevator cores only

(don’t glue the elevator ribs to the elevator LE yet) making

sure the cores remain perpendicular to the LE’s as you

proceed. You can see the ribs in the following photo.

❏

7. Make the elevator hinge blocks from a 1/4" x

5/16" x 24" balsa stick and 1/4" x 5/16" balsa you have

leftover from the rib jigs when you were building the

stab. Glue the hinge blocks to the elevators as shown on

the plan. Now you may glue the elevator ribs to the LE.

❏

8. Proceed slowly and carefully, shaping the elevator

ribs and the hinge blocks to match the elevator LE and

the cross section on the plan. Make sure you sand the

ends of the ribs to a point as shown in the sketch.

Otherwise, covering the elevators will be difficult.

There. Now you have a nicely constructed stab with

elevators that accurately match. Just a few more things

to do and then we’ll move on to the fin and rudder

(which version are you going to build?)

.

❏

9. Determine which side of the stab looks the best.

Designate that side as the top. Use a file or a rotary tool

with a cut-off wheel to remove sharp edges or burrs on

the ends of the elevator joiner wire. Position the elevator

joiner wire on the top of the stab as shown in the photo.

Mark the leading edge of the elevators where the

arm

portion of the joiner wire will enter as shown on the plan

❏

10. Carefully

break

both elevators free from the stab.

Note which elevator matches which side of the stab.

Remove any

glue bumps

left from the CA you used to

tack glue the elevators to the stab.

❏

11. Insert T-pins through the center of one of the

elevators LE’s, near the tip and near the root. Place a

straightedge across the T-pins and draw the centerline

on the elevator LE with a ballpoint pen. Draw a

centerline along other elevator LE and the TE of the stab

the same way.

DC-3

Fact

After presiding over various projects including the

Martin MB-2 bomber at the Glenn L. Martin

aircraft company, Donald W. Douglas Jr, born

April 6, 1892, co-founded the Davis-Douglas

Aircraft Company in the spring of 1920 with help

from David Davis, a millionaire with a great desire

to fly. By the mid 20's, Douglas designs were well

known throughout both the civilian and military

aircraft industry.

- 13 -