Top Flite TOPA0500 User Manual

Page 54

❏ ❏

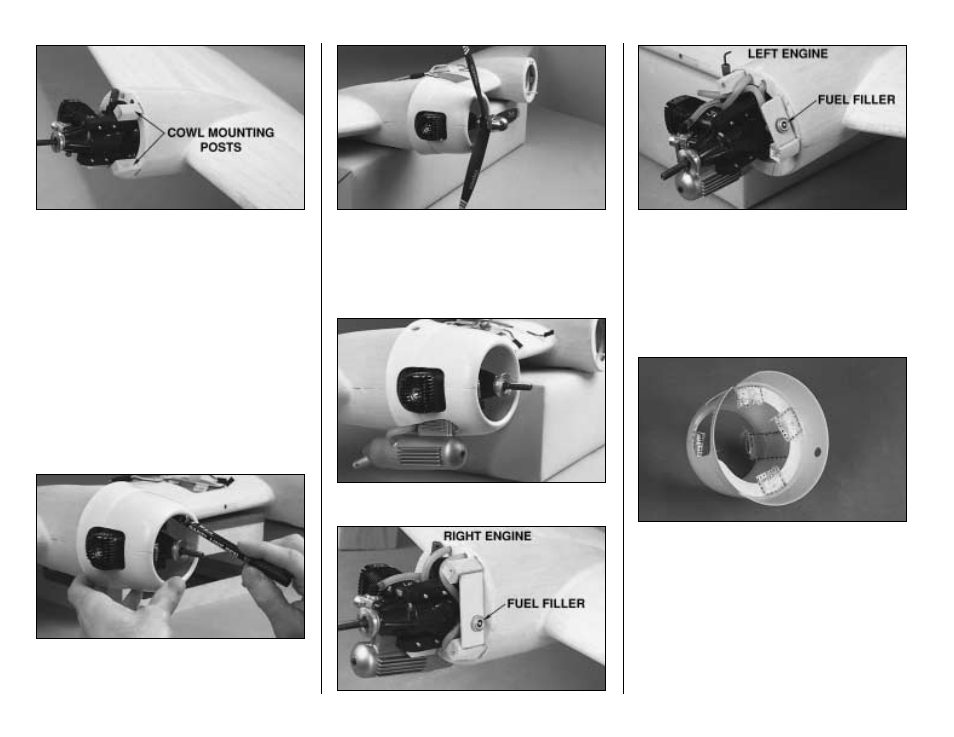

5. Mount your engine to one of the nacelles (we did

the right side first). If necessary, trim part of the cowl

rings to accommodate the engine mount. Glue the

1/2" x 1/2" x 1-1/16" basswood cowl mounting posts in

the notches you cut in the balsa cowl ring. Slightly round

the outer edge of the cowl mounting posts to

accommodate the cowl.

❏ ❏

6. Determine where to trim the cowl to accommodate

your engine. Start by cutting a small hole, then enlarge

the hole until you can fit the cowl over your engine. After

you mount the cowl, you can accurately finish cutting the

rest of the hole for the best appearance.

❏ ❏

7. Position the cowl on the cowl mounting posts and

center it over the nacelle and your engine. Mark the cowl

rear over the cowl mounting posts where to drill the

holes for the mounting screws.

❏ ❏

8. Remove the cowl. Drill 3/32" holes in the cowl at the

marks you made. Reposition the cowl and mark the cowl

mounting posts for the mounting screws. Remove the cowl

and drill 1/16" holes in the cowl mounting posts. Mount the

cowl with three #2 x 1/2" screws

(we installed a propeller

and a spinner hub on ours just to see how it looks!).

❏ ❏

9. Cut your cowl for the muffler and needle valve.

❏ ❏

10. Make a fuel filler mount from leftover 1/8"

plywood and mount your fueling system. Cut your fuel

lines to the correct length and connect them to your

engine, fueler and the pressure tap on your muffler. Cut

a hole in the cowl to access your fuel filler.

❏

11. Fit and mount the cowl to the other nacelle the

same way

.

❏

12. If you haven’t done so already, roughen the inside

of both cowls along the seams so epoxy will adhere.

Also roughen the back of the cowl rear where the

mounting screws go through. Use 30-minute epoxy to

apply strips of 1" glass cloth over the seams and the

holes where indicated.

❏

13. Allow the epoxy to cure overnight and trim the

excess off. Fill the seams between the right and left cowl

halves with filler. We use Bondo automotive filler or

Squadron Green or White putty. Allow the filler to fully

harden, then wet sand smooth.

- 54 -