Fact, Dc-3, Finish the bottom of the fuse – Top Flite TOPA0500 User Manual

Page 28

of the horn on the elevator joiner wire. Move the elevator up

and down and make sure you can get all the throw

recommended on page 62 of the manual. If necessary,

enlarge the slot in F12 or the slot in the TE of the stab.

While we’re at it, let’s mount the elevator and

rudder servos.

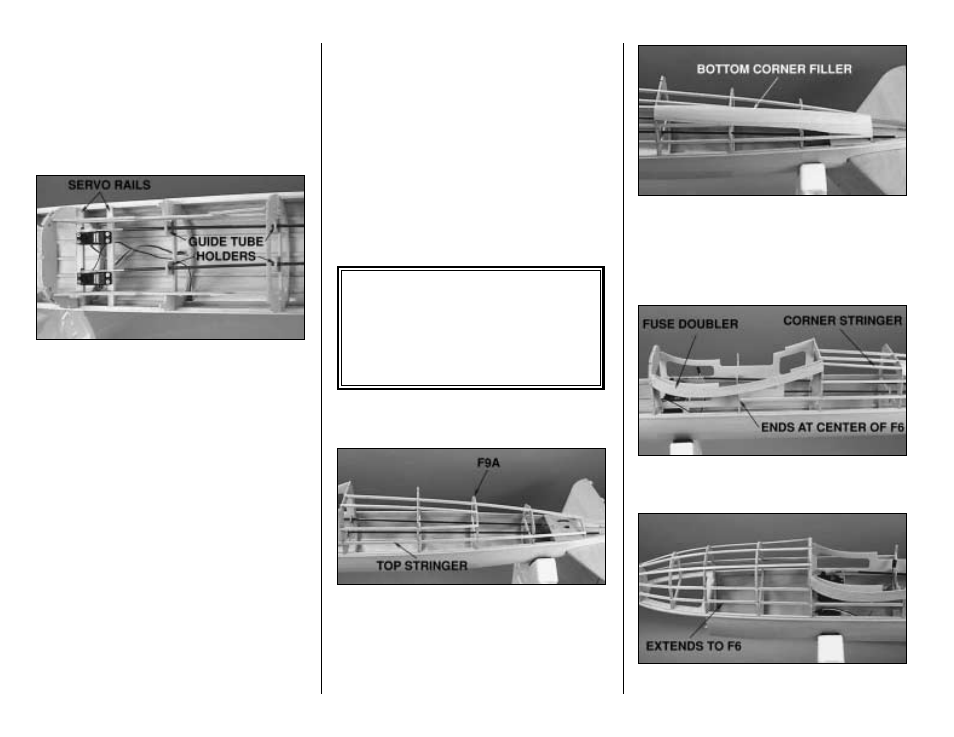

Refer to this photo for the following six steps.

❏

14. Use a 1/4" x 3/8" x 36" basswood stick to make

the servo rails. Glue the front rail between the main

stringers and to former F5. Use the servos to set the

location of the aft servo rail. Make sure you position the

aft rail with enough space to permit you to remove the

servos if you need to later on. Glue the aft rail to the side

stringers and the inner wing saddles.

❏

15. Use the screws included with the servos to mount

your servos to the servo rails where shown on the plan.

❏

16. Cut both pushrods to the correct length and silver

solder a threaded coupler to them.

❏

17. Drill a 3/16" hole at the punch mark through the

die-cut 1/8" plywood guide tube holders. Slide four

guide tube holders over the elevator guide tube and two

guide tube holders over the rudder guide tube. Connect

the pushrods to the servos with a nylon clevis.

❏

18. Make sure your pushrods are the correct length

and your clevises are threaded on the right amount so

that when your servos are centered, the rudder, tail gear

wire and the elevator are neutral. Now is the best time to

make adjustments if any are needed.

❏

19. Glue the guide tube holders to the formers where

shown on the plan so the guide tubes align with the servos.

Position the guide tubes so the ends don’t interfere with the

servos or controls. Glue the guide tubes to the formers and

tube holders with medium or thin CA.

❏

20. Make sure the ball stud is secure on the rudder

steering arm with thread lock and the 0-80 nut. Glue the

tail gear plate to the main stringers. Keep the tail wheel

centered. Glue the rudder torque rod bearing tube to the

stab with medium CA. Be careful not to get any CA into

the bearing tube.

❏

21. Unscrew the #2 screws that hold the tail gear

bracket to the tail gear plate and take the tail gear off the

plate. Set the tail gear and the screws aside for now.

FINISH THE BOTTOM OF THE FUSE

❏

1. Cut and glue the stringers for the aft right side of

the fuse bottom from three 3/16" x 3/16" x 30" balsa

sticks and glue them in place as shown in the photo.

The top stringer ends in the middle of former F6 (refer to

the photo at step four).

❏

2. Sand the aft end of the stringers at F9A to

accommodate the bottom corner fillers.

❏

3. Cut two 15" long bottom corner fillers from the

1/4" x 1-3/4" x 30" balsa sheet. Trim the aft end of one of

one bottom corner filler to fit between the stringers at

F11. Glue that corner filler to formers 8 through 11 on

the right side of the fuse as shown in the photo and on

the plan. Sand the corner filler as shown in the cross

sections on the plan.

❏

4. Glue the die-cut 1/8" balsa fuse doubler to formers

F5, F6 and F7, then glue a corner stringer between

former F7 and the front of the corner filler.

❏

5. Glue the 3/32" x 3/16" x 30" stringers in the notches

of the formers in the front of the fuselage. Note that

DC-3

Fact

The one and only DC-1 served a full career with

TWA, then was sold to Howard Hughes. Hughes

sold the airplane to the Spanish government, but

the DC-1 met its demise after an engine failure

during takeoff in 1940.

(Guess they didn't read the

“Engine Out” section in our manual.)

- 28 -