Final construction, Mount the wing to the fuselage, Build the wing fillet – Top Flite TOPA0500 User Manual

Page 55: How to make a drill jig - 55

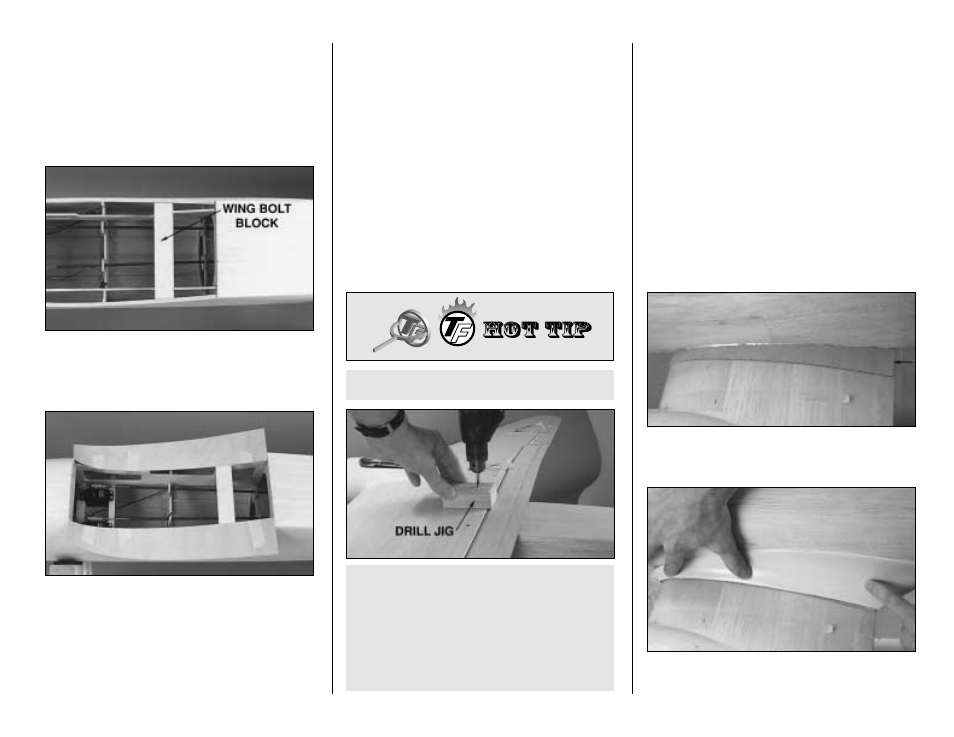

FINAL CONSTRUCTION

MOUNT THE WING TO THE FUSELAGE

❏

1. Cut the 1/4" x 2-3/4" dowel into two 1-3/8" long

wing dowels. Round one end of both wing dowels and

glue them into the wing with 30-minute epoxy.

❏

2. Trim the ends of the 1/4" x 1" x 5-3/8" plywood

wing bolt block so it fits between the fuse sides in the

inner wing saddles. Securely glue the wing bolt block to

the saddles and fuse sides with 30-minute epoxy.

❏

3. Trim the balsa fuse sides so they are even with the

ply inner wing saddles. Make the wing fillet bases from

the 5" x 13" x 1/32" plywood sheet using the pattern on

the fuse plan. Tape both wing fillet bases to the inner

wing saddles in the fuselage.

❏

4. Test fit the wing to the fuselage. If necessary,

slightly enlarge the holes in former F5 to accommodate

the wing dowels.

❏

5. Use the

pin-and-string technique

to align the wing

the same way you did the stab, only this time stick the

T-pin in the center of the fuselage at the rear.

❏

6. See the Hot Tip and the photo that follows and use

a #10 (or 3/16") drill to drill holes in the wing bolt blocks

in the fuselage. The wing must not shift during this

procedure or you will lose your alignment and you must

hold your drill perpendicular to the bottom of the wing.

Secure the wing to the fuselage with masking tape or

weights if necessary. Steady your hands and drill the

first hole. If you seem to have had difficulty with this

procedure in the past, you could just

dimple

the wing

bolt block by letting the spinning drill bit

barely

contact it

and

backing off

before you actually drill a hole. Remove

the wing and make sure you will be drilling near the

center of the block. Reinstall the wing, check alignment

and drill the other hole.

❏

7. Take the wing off the fuse. Tap threads in the wing

bolt block with a 1/4-20 tap. Saturate the threads in the

wing bolt block in the fuse with thin CA. Allow the glue to

cure thoroughly, then re tap the holes. Enlarge the

holes in the bottom sheeting to accommodate the heads

of the wing bolts. Bolt the wing to your fuselage with

1/4-20 nylon wing bolts.

BUILD THE WING FILLET

❏

1. Bolt the wing to the fuselage and view the model

from the rear. Observe the horizontal alignment between

the wing and the stabilizer. If necessary, loosen the wing

bolts and insert shims from leftover balsa between the

wing fillet bases and the fuselage to bring the wing into

alignment with the stab. Tighten the wing bolts.

❏

2. Make sure the aft edge of both wing fillet bases

end

at the trailing edge of the wing. If necessary, reposition

or trim the fillet bases to achieve this.

❏

3. Cut the molded plastic wing fillets along the

cutlines. With the wing bolted to the fuselage, test fit the

wing fillets to the fuselage so you can see how they fit.

If you have a drill press (or if a friend will let you use

his), make a

drill jig

by drilling a #10 hole through an

approximately 1" x 1-1/2" x 2" hardwood block. Use

the block to hold your drill bit perpendicular to the

bottom of the wing as you drill the holes. This will help

you

aim

the drill directly toward the wing bolt blocks

so the heads of your wing bolts will rest flat on the

wing bolt plate in the wing. You can use this drill jig on

all your models.

HOW TO MAKE A DRILL JIG

- 55 -