Top Flite TOPA0500 User Manual

Page 46

❏ ❏

3. Enlarge the holes in the hatch cover only with a

3/32" drill bit.

Countersink

the holes for the #2 x 3/8" flat

head screws with a countersink or Dremel #178 bit. Test

fit the hatch cover to the rails with the screws. If

necessary, sand the edges of the hatch cover so they

align with the edges of the hatch opening.

Note: If you find it difficult to countersink the holes in the

hatch cover for the flat head screws, you could use

regular #2 x 3/8" screws (not supplied) and not

countersink the holes.

❏

4. Fit the right hatch cover the same way.

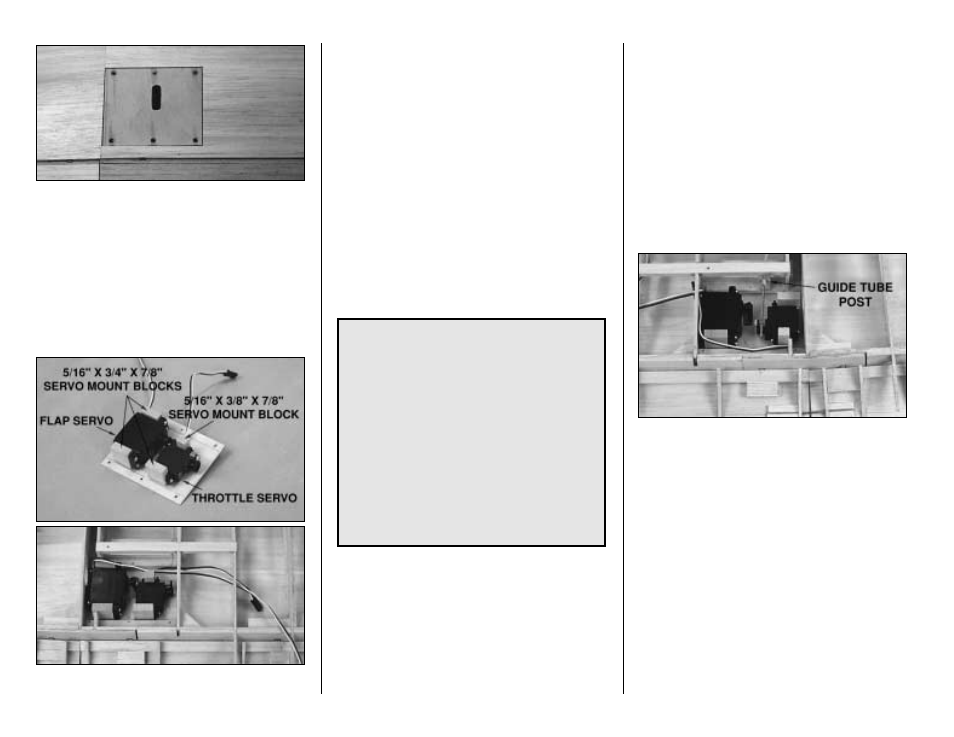

Refer to these photos to mount the flap and throttle

servos to the hatch cover. We’ll mount the flap servos

first because there’s only one place you can mount them

(which is determined by the hole in the hatch covers).

Whatever room left is for the throttle servo. The photos

show the left hatch. If you’re not building flaps, disregard

parts of this section that involve the flap servos.

❏ ❏

5. Mount one of your flap servos to two 5/16" x 3/4"

x 7/8" basswood servo mount blocks. Position the

servo with the mount blocks on the left throttle/flap servo

hatch cover (which should still be in the wing). Mark the

location of the mount blocks on the hatch cover so you

will know where to glue them. Remove the hatch. Scuff

the hatch cover where the blocks will go with coarse

sandpaper so the glue will adhere. Use 30-minute epoxy

to glue the servo mount blocks to the hatch cover.

❏

6. Mount your other flap servo to the right hatch cover

the same way.

❏ ❏

7. Make a 5/16" x 3/8" x 7/8" servo mount block

from a 5/16" x 3/4" x 7/8" servo mount block. Mount one

of your throttle servos to a 5/16" x 3/8" x 7/8" servo

mount block and a 5/16" x 3/4" x 7/8" servo mount block.

❏ ❏

8. Position the throttle servo with mount blocks on

the left hatch cover (temporarily placed in the wing) to

determine its mounting location on the hatch. Make sure

you position the servo so that it will not interfere with the

mounting screws on your flap servo (so you will be able

to unscrew the screws and remove your servos later if

needed).

❏ ❏

9. Remove the hatch cover and glue the servo mount

blocks to the hatch cover in your predetermined location.

❏ ❏

10. Place the hatch cover with the servos in the

wing. Cut the throttle cable guide tube to the correct

length. Cut the 36" throttle cable to the correct length,

then slide it through the guide tube and connect it to the

servo with a screw-lock pushrod connector.

❏ ❏

11. Mount your other throttle servo to the servo

mount blocks, determine the mounting location and glue

the blocks to the right servo hatch cover. Mount the

hatch cover and connect the servo to the throttle cable.

On our model, we made a guide tube post from leftover

balsa to align the throttle cable with the servo.

❏ ❏

12. Cut your throttle cables to the correct length

and connect them to your engine with screw-lock

pushrod connectors. Some may prefer to hook up the

carburetors after the model is finished but we

recommend you finalize your throttle setup now before

you begin sheeting. It’s easier to view everything and fix

it now instead of when the wing is fully sheeted.

❏ ❏

13. Cut the openings in the outer panels for the

die-cut 1/16" plywood aileron servo hatch covers and

mount the hatches to the rails the same way you did for

the flap/throttle hatch covers.

Note: For convenience of hookup, the throttle

servos shown in the photo and on the plan are not

mounted in the same direction. This requires that

the servos be mixed electronically (instead of using

a Y-connector, since one of your servos will have to

be reversed in order for both carburetors to open

and close simultaneously). Refer to

Setup your

throttles

on page 62 to electronically mix your

throttles. If the radio you plan to use is not capable

of mixing the servos electronically, mount both

servos the same way. In any regard, the servo

mounting location shown on the plan and in the

manual is our suggestion but there are other ways

to hook up your throttle servos. Whatever method

you decide upon, plan carefully and test your setup

before you proceed.

- 46 -