Fact, Dc-3 – Top Flite TOPA0500 User Manual

Page 24

❏

15. Now that you are sure the stab will align, remove it

and apply 30-minute epoxy to the joining areas and glue

it to the fuse sheeting and the ply stab saddle. Use the

pin-and-string technique to recheck your alignment.

make sure your stab is level and the incidence is

correct. Wipe away excess epoxy before it cures. Do not

build up a fillet between the stab and the fuse. Do not

disturb the fuse until the epoxy is fully cured.

❏

16. Notch the LE of the fin as necessary to accommodate

former F10 and reposition the fin and rudder on the stab.

Mark the rudder where the rudder torque rod will enter.

❏

17. Remove the rudder and drill a 1/8" hole through

the rudder base at the mark you made. Cut a groove in

the rudder LE so you can insert the rudder torque rod.

The scale rudder is shown in the photo. The groove in

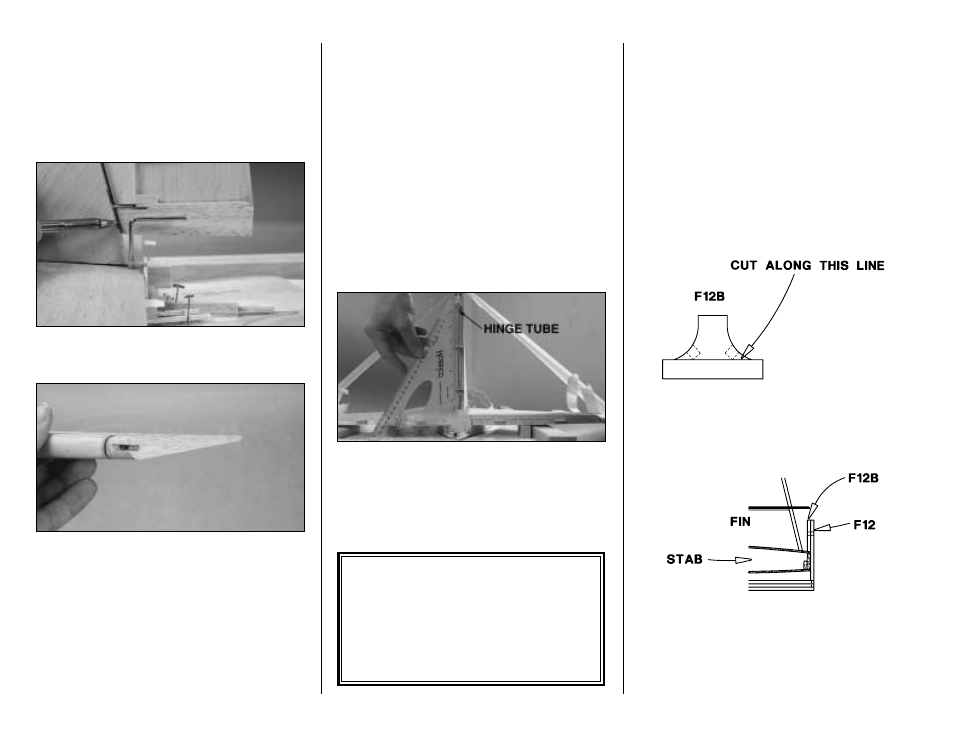

the LE of the non-scale rudder would be similar to the

groove in the elevators for the joiner wire.

Skip this step if you are building the non-scale fin

and rudder.

❏

18. Enlarge the groove in the bottom of the TE of the

fin to accommodate the rudder torque rod and the

bearing tube.

❏

19. Test fit the fin and rudder to the stab with the

torque rod. Make adjustments where necessary so the

torque rod fits all the way into the rudder and you can

freely pivot the rudder side to side.

❏

20. Remove the rudder from the fin. Refer to the

following photo. Align the hinge tube on your scale fin (or

the centerline on the TE of the non-scale fin) with a 90

degree triangle on your building board. If necessary, sand

the sheeting on the high side of the fin to get it vertical.

❏

21. After you are satisfied with the fit of the fin to the

stab, remove the fin from the stab. Apply a film of

30-minute epoxy to the base of the fin and to the stab

sheeting. Reposition the fin on the stab, aligning the

rudder torque rod with the center of the fin TE. Align the

LE of the fin with the centerline on the plan. Immediately

proceed to the next step.

❏

22. Hold the fin vertical with masking tape strapped

across the top of the fin over to both stab tips. Adjust the

tension on the masking tape to pull the fin to one side or

the other until it is vertical. Temporarily join the rudder to

help make sure the fin is aligned with the rudder torque

rod. Re-check alignment and do not disturb the fin until

the epoxy is fully cured.

Now let’s sheet the top of this thing and get it off your

building board...

SHEET THE TOP OF THE FUSELAGE

❏

1. Remove any T-pins you have in the main stringer

inside the fuselage and stick them through the main

stringer outside the fuselage.

❏

2. Cut the die-cut 1/8" balsa former F12B as shown in

the sketch. Glue F12B to the front of former F12 on top

of the stab. Note that F12B is slightly smaller than F12.

This is to provide a small

ledge

to support the sheeting.

DC-3

Fact

Probably the greatest contributing factor to the

acceptance of the DC-1 by TWA officials (and a

subsequent purchase order for twenty more

“improved” versions—the DC-2) was the ability of

the DC-1 to take off on a single engine! TWA paid

Douglas $125,000 for that first DC-1, though it

cost Douglas $807,000 to build.

- 24 -