LAARS NeoTherm LC NTV1700 - Install and Operating Manual User Manual

Page 81

NeoTherm LC Boilers and Water Heaters

Page 77

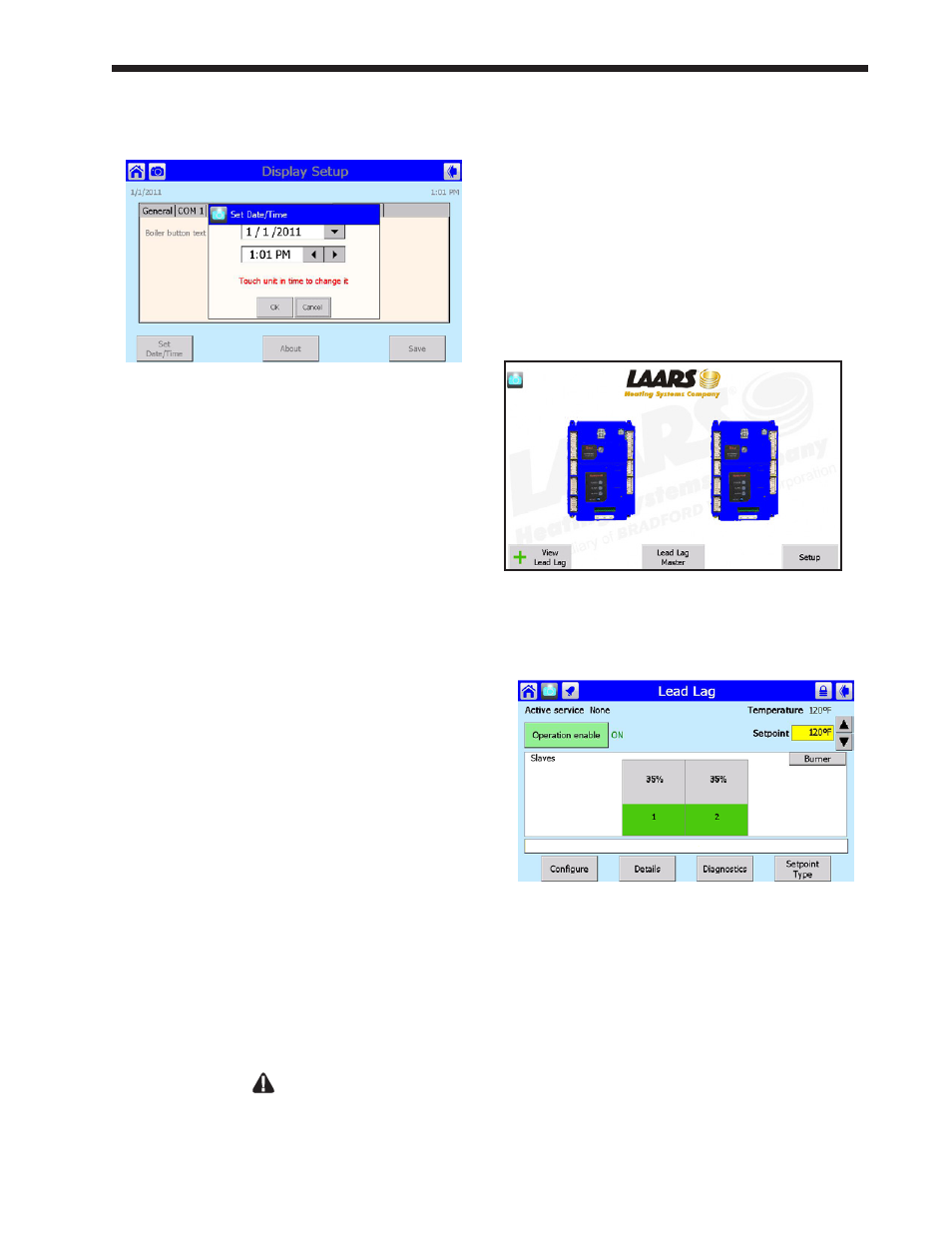

4. Select Date and Time. Figure 107 shows the

setup screen.

Fig. 110 – Date and Time

9.5

Setup for Domestic Hot Water on

a Lead/Lag System

There are three ways that a NeoTherm LC system

can be set up to provide domestic hot water. Two

of them involve the use of an indirect water heater.

In a system including an indirect water heater, hot

water is circulated through a piping loop which

runs through an insulated water tank. Heat from

the water in the loop is transferred to the water in

the tank, and the heated water in the tank is used as

domestic hot water.

Setup Type 1 –

All of the boilers in the system can be set up to react

together if there is a call for domestic hot water.

This arrangement can be used for NTH or NTV

units. When NTH units are used in this kind of

setup, the demand for domestic hot water (DHW) is

given priority over the demand for central heat (CH).

If the system is producing heat for a CH demand,

and a call for DHW arrives, all of the boilers will

stop producing heat for CH, and the whole system

will respond to the DHW demand. The DHW pump

will start circulating water through the loop in the

indirect water heater. The System sensor is used to

control modulation in this configuration, so sensor

placement is critical.

This arrangement can be cumbersome if the demand

for domestic hot water is a lot less than the demand

for central heating. This can result in multiple

boilers “idling” as they wait for the DHW demand to

be satisfied.

Caution

For NTH units - This arrangement can only be

used in applications where all of the components

in the system are rated for both the maximum

hydronic temperature and the maximum DHW outlet

temperature.

The setup for this is all done from within the Lead/

Lag system. You will need to set up an LL CH

setpoint and a separate LL DHW setpoint, and assign

the priority to the DHW demand.

The input from the aquastat is brought to terminals

5 and 6 on TB6 on the controller which is acting as

the Lead/Lag Master. (Usually, this is the Primary

controller on Boiler 1.)

1. From the ‘home’ screen (Fig. 111), press the

View Lead Lag button.

Fig. 111 – ‘home’ screen

2. Press the button for Lead Lag Master. Fig.

112 shows the screen that follows.

Fig. 112 – Lead/Lag Master Screen

3. Press the Configure button. The display will

present the Lead/Lag Master Configuration

Screen (Fig. 113).