LAARS NeoTherm LC NTV1700 - Install and Operating Manual User Manual

Page 119

NeoTherm LC Boilers and Water Heaters

Page 115

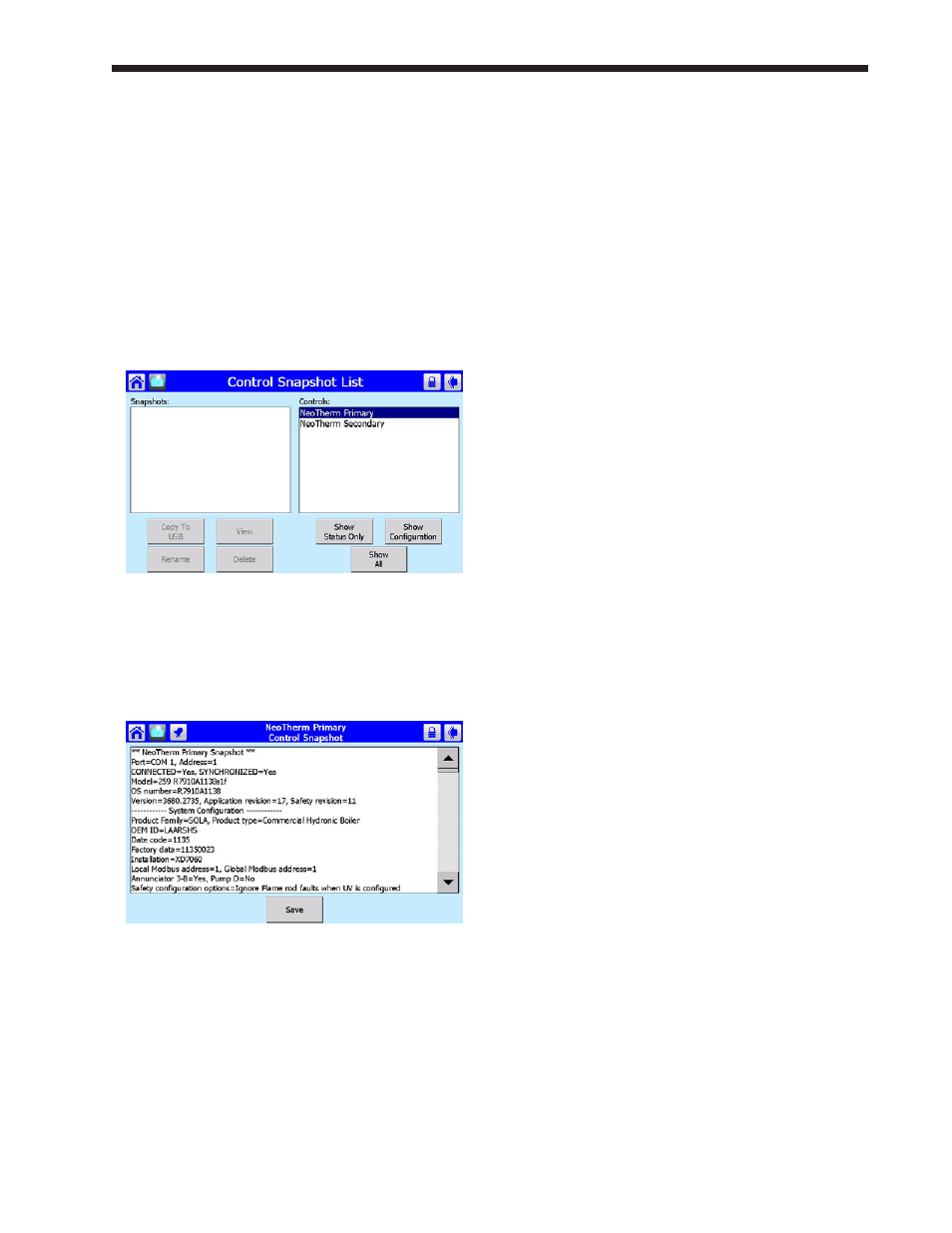

12.8 Control Snapshot

The software allows you to take a “snapshot” of

the current state of the controller, including setup

information and operating information. This

information can be helpful during troubleshooting.

How to get there – Snapshot button> Control Snapshot Screen Figure 138 shows the Control Snapshot screen. Fig. 138 - Control Snapshot List Screen Select one of the controllers listed on the right side of the screen. Press one of the buttons below the right column to see the snapshot. See Fig. 139. Fig. 139 - Typical Control Snapshot The Show Status button captures the current status of the I/O of the control only. Show Configuration captures the current parameter settings and the control setup. You can save the snapshot, give it a name, or send a copy to the USB port. 12.9 Operating Sequence Initiation one of these conditions: • Initial power up • Voltage fluctuations vary +10% or -15% • Frequency fluctuations vary ±10% • The demand, limit control input, or TT signals are interrupted during the prepurge period. • After the Reset button is pressed. • After a Fault is cleared using the displays. The Initiation sequence also delays the boiler demand from being energized and re-energized from an intermittent AC line input or control input. If an AC problem exists for more than 240 seconds, a lockout will occur. Start-Up Checks in a Lead/Lag System first part of Section 9. In this section, we will focus on the aspects of Lead/Lag that might be helpful in troubleshooting. controller acting as the Lead/Lag Master goes through a “synchronization” process. During synchronization, the controller establishes communications with each of the Slave controllers via the Modbus link. The Slave controllers download some setup parameters and operating history information. (On a system with several boilers, this phase can take several minutes.) If the Master cannot establish communications with one of the Slaves, it triggers a Hold or Lockout. valves. If the Master cannot determine whether a flap valve is open or closed, or if it cannot locate the correct number of flap valves, it triggers a lockout or hold. each of the individual controller and burner combinations is free to operate in the normal way. The self-check and firing sequence for each individual controller and burner combination is described in the following section.

Home Page

Each controller enters the Initiation sequence after

For an explanation of Lead/Lag operation, see the

When a Lead/Lag system is first powered up, the

The Master also checks the status of each of the flap

If the system passes the checks described above,