LAARS NeoTherm LC NTV1700 - Install and Operating Manual User Manual

Page 49

NeoTherm LC Boilers and Water Heaters

Page 45

In either kind of installation, a system sensor is

usually used to monitor the demand. The input from

this sensor is used to control the modulation rates of

the operating burners.

Boiler

Burner

Position

Control

Master/Slave

Assignment

Modbus

Control

Address

1

Upper

Primary

Lead/Lag Master,

also Slave 1

1

1

Lower

Secondary

Slave 2

2

2

Upper

Primary

Slave 3

3

2

Lower

Secondary

Slave 4

4

3

Upper

Primary

Slave 5

5

3

Lower

Secondary

Slave 6

6

4

Upper

Primary

Slave 7

7

4

Lower

Secondary

Slave 8

8

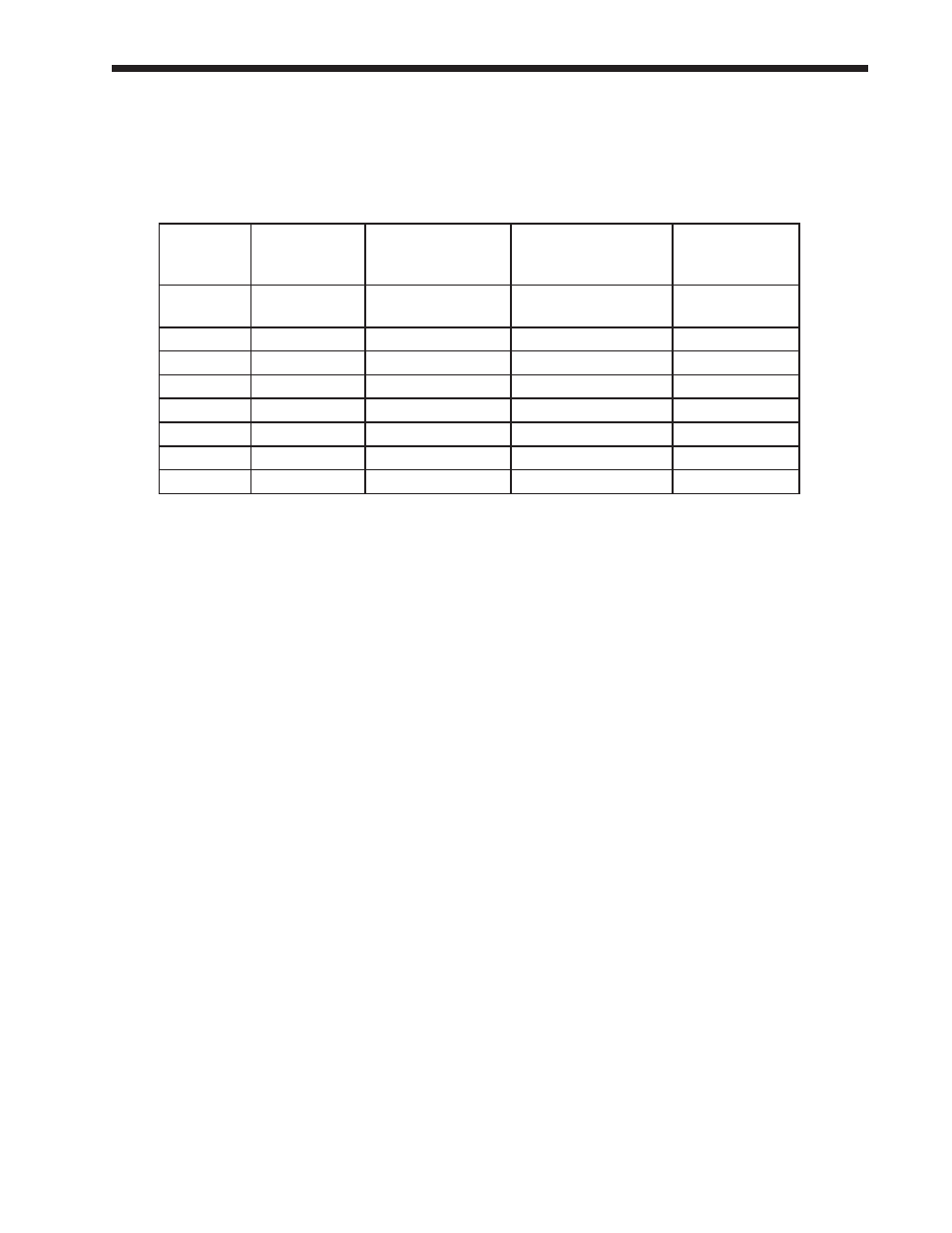

Table 11 – Master/Slave Assignments and Modbus Control Addresses

9.1.2

Lead/Lag Modulation Cycle

Note - We will explain the modulation cycle here,

in case you need to understand how the Lead/Lag

system actually operates. If you are just installing

the unit(s) and want to skip this section, just

remember that, as the heating demand increases,

the Lead/Lag system puts more burners on-line.

As the heating demand is reduced, the Lead/Lag

system shuts off some of the burners.

A Run sequence is initiated when the system

temperature falls to the setpoint less the On

Hysteresis value. The default setting for On

Hysteresis is -5°F, but this is adjustable. The

setpoint used to initiate the Run sequence is the

Lead/Lag Central Heat setpoint.)

The Lead/Lag controller decides which burner is

assigned to start first. This assignment is rotated

across all of the available burners so that any one

burner does not run significantly longer than the

others. The Lead/Lag controller tracks the run

times for all of the available burners, and uses this

to calculate the starting order for the burners. This

means that each time the system starts up, a different

burner may start first. It also means that the Primary

burner on a particular boiler may start first one time,

and the Secondary burner for that boiler may start

first the next time.

When the Run sequence is initiated, the burner with

the least amount of runtime will fire. If the heating

demand increases so that the firing rate of that first

burner rises to 65% fan speed (the Base Load value),

the next burner in the sequence will start up and

begin firing at 35% fan speed. After this, both of the

active burners will modulate up or down together, in

reaction to the changes in demand. See Fig. 50.

If the system loop temperature rises above

the LL CH setpoint, then the two burners will

simultaneously drop their fan speeds. If both boilers

drop to their minimum fan speeds (29%), then the

second burner will drop out.

If the heating demand continues to increase, and

the system loop temperature continues to drop,

then the two burners will increase their fan speeds

together. When they reach 65%, the next burner in

the sequence will start up and be added to the group.

All three boilers will continue to fire simultaneously

at equal input rates.

If the modulation rate for all three burners drops

to the minimum fan speed (29%), the last burner

started will drop out. If the demand continues to

drop, the second burner started will also drop out.

If the system temperature reaches the LL CH

setpoint value plus the Off Hysteresis figure, all of

the burners will shut off. (The default setting for Off

Hysteresis is +5°F, but this is adjustable.)

If any of the boilers approaches its high limit

temperature, that boiler will modulate back to stay

below the high limit.

As the heating demand continues to change, the

Lead/Lag Master will continue to add, remove, or

modulate the additional boilers in the system.

Let’s consider the following example:

Four NeoTherm LC boilers are tied together via

Modbus connections. Here are the Master/Slave

assignments and the Modbus control addresses: