LAARS NeoTherm LC NTV1700 - Install and Operating Manual User Manual

Page 75

NeoTherm LC Boilers and Water Heaters

Page 71

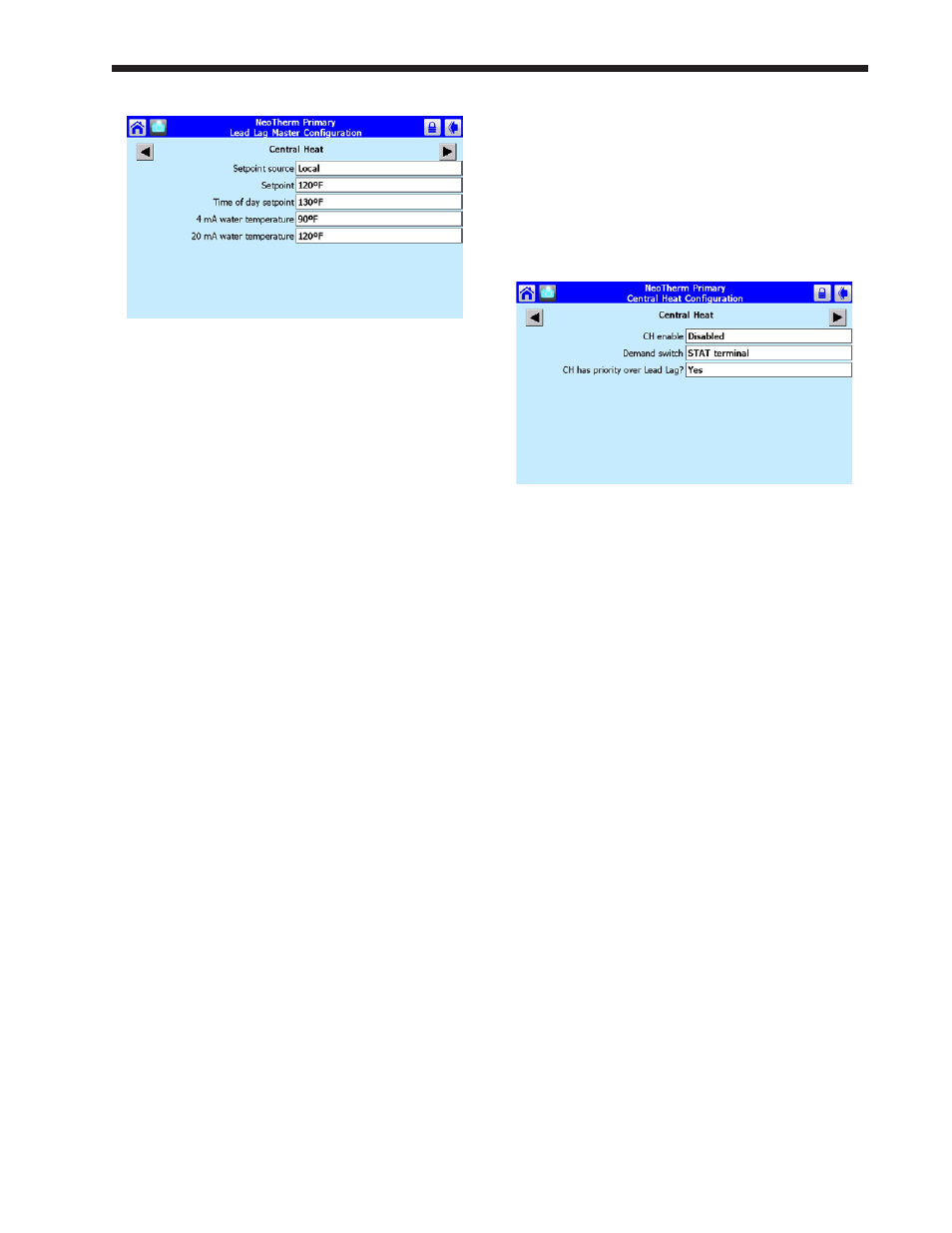

Fig. 95 – Lead Lag Central Heat Configuration

3. Change the 4 mA water temperature to match

the lowest water temperature setting on the

Building Automation System or multiple

boiler control.

4. Change the 20mA water temperature to match

the highest water temperature setting on the

Building Automation System or Multiple

boiler control.

Note - Laars offers “gateways” to allow connections

to BACnet, LON, and other communications

protocols. See Section 9.6.

Job N - Building Automation or Multiple

Boiler 4-20 mA Modulation Control

(This is an individual function – do this on each of the controls.)

In this type of installation, the fan speed of each

boiler is changed or modulated by a source outside

of the boiler. All active burners must operate at the

same modulation rate while operating. The system

will not operate correctly if some of the burners

are being asked to operate at full rate while other

burners are operating at minimum rates.

Note - The system can also operate using 0 - 10V dc

using a converter (Laars part number CA006100.)

1. On each controller in the system, check

terminals 5 and 6 on TB7 to ensure that the

System sensor is not connected. (For this type

of operation, the Lead/Lag system is disabled.)

2. Connect the 4-20 mA input to each controller

in the system.

• On the Primary controller in each boiler,

connect to terminals 3 and 4 on TB7.

• On the Secondary controller in each boiler,

connect to terminals 7 and 8 on TB7.

3. Enable a central heat call for each control

on the system. This function must be set up

for each controller separately. This function

operates outside of the Lead/Lag system.

How to get there – Central Heat Enable

Home Page

NeoTherm LC Primary Screen

Primary Configuration Menu

4. Fig. 96 shows the setup screen.

Fig. 96 - Central Heat Configuration

5. Enable the Central Heat function on the top

line. Give the CH function the priority using

the lower line.

Note - Laars offers “gateways” to allow connections

to BACnet, LON, and other communications

protocols. See Section 9.6.

Job O – Combustion Setup Procedure

(These are individual functions. Do the combustion setup for

each of the burners.)

In this section, we will explain how to set up the gas

valve so both burners in each boiler run efficiently

at both the High Fire and Low Fire conditions. As

we said, a boiler includes two controllers (Primary

and Secondary), which control two burners (Primary

and Secondary). See Fig. 97. Each burner has

a separate gas valve, and each of these must be

set up separately. Here’s a quick summary of the

procedure:

•

You shut off one controller/burner

combination, and work with the other.

•

You set the working burner to run at High Fire,

and adjust the gas valve to get the correct CO

2

reading.

•

Next you set the same burner to run at Low

Fire, and make another adjustment on the gas

valve to get the desired CO

2

reading.

•

When you are through, you shut off the

controller/burner you have been working with,

turn on the other controller/burner, and make

the same adjustments there.