1 review of lead/lag control system, Laars heating systems – LAARS NeoTherm LC NTV1700 - Install and Operating Manual User Manual

Page 48

LAARS Heating Systems

Page 44

Section 9

SETUP AND CONFIGURATION

9.1

Review of Lead/Lag Control

System

9.1.1

About Lead/Lag Operation

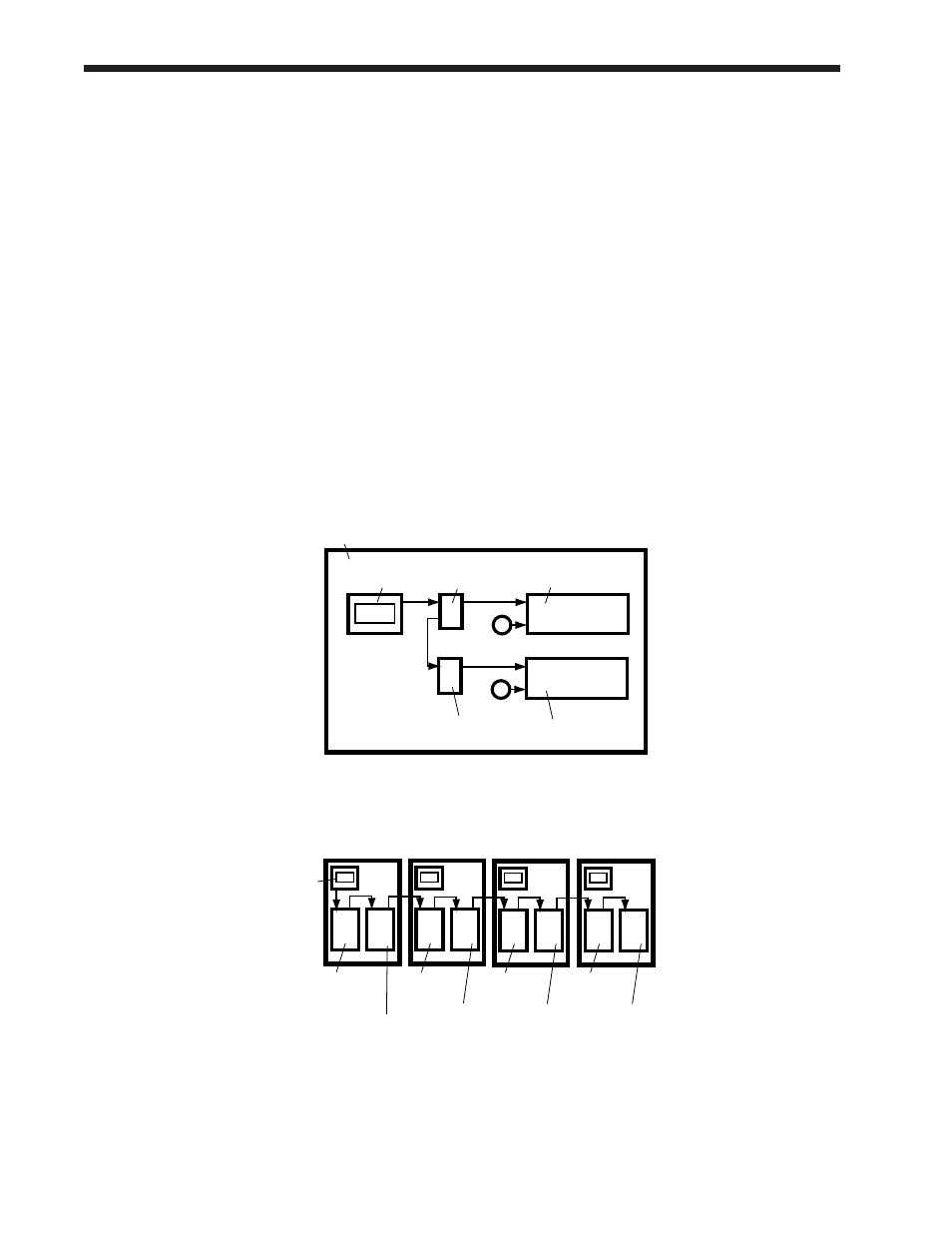

The boilers in this series are always set up for Lead/

Lag operation. In a single-boiler installation, there

are two controllers and two burners, as shown in Fig.

49. The controller for the upper burner is set up as

the Primary control. For control purposes, this is

the Lead/Lag Master and also operates as Lead/Lag

Slave 1. The control for the lower burner is set up

as the Secondary control and operates as Lead/Lag

Slave 2.

On a multiple-boiler installation, each individual

boiler is still set up as shown in Fig. 48. The boiler

controls are arranged in a “daisy chain” using a

Modbus connection, with the Secondary control

of one boiler connected to the Primary control of

the next boiler. Up to four boilers, with up to eight

controllers, can be connected in this way. See Fig. 49.

Fig. 48 – Lead/Lag Arrangement in a Single-Boiler Installation

Fig. 49 – Lead/Lag Arrangement in a Multiple-Boiler Installation

Primary

burner

Primary

controller

Gas

valve

Gas

valve

Secondary

controller

Secondary

burner

Operator

interface

Boiler 1

Operator

interface

Boiler 1

Slave 4

Boiler 2

Slave 3

Slave 2

Lead Lag

Master and

Slave 1

Slave 6

Boiler 3

Slave 5

Slave 8

Boiler 4

Slave 7

Addr

1

Addr

2

Addr

3

Addr

4

Addr

5

Addr

6

Addr

7

Addr

8