E.1.4 using the sensor on the crank, E.1.5 typical set-ups – s3 – Haltech F10X User Manual

Page 106

F10X Manual

106

E.1.4 Using the Sensor on the crank

After a suitable mounting location for the sensor has been found the engine should be

positioned at approximately 75

° BTDC on cylinder no.1 compression. The magnet should

now be placed in the aluminium disk, making sure the magnet is in line with the sensor when

the engine is in this position. This is now the reference point for all the other magnets. The

number of cylinders will determine the number of magnets required and the angle of

installation. If the sensor is to be used on the Camshaft, the number of magnets will need to be

doubled. The adjustment of the air gap will be determined by the strength of the magnets

used. This should be tested once the wheel assembly has been installed. Typical air gap is (2 –

8mm) Checking the Engine Data page for steady RPM is usually a good indication that the air

gap is acceptable.

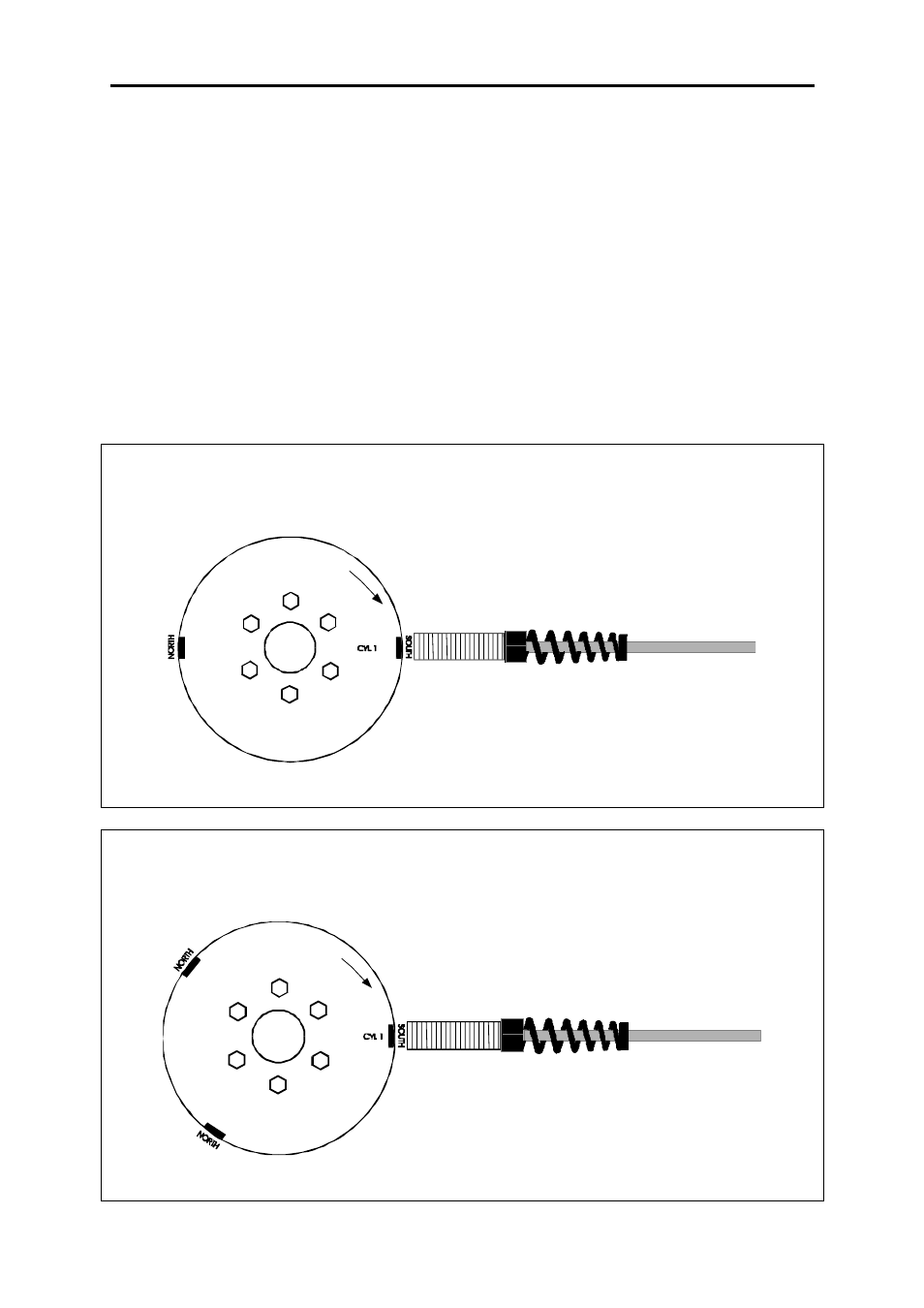

E.1.5 Typical set-ups – S3

4 cylinder / 2 rotor Engine

For a four cylinder 2 magnets are required in total, positioned exactly 180

° apart.

Figure 1: Typical 4 cylinder/ 2 rotor application

6 Cylinder / 3 Rotor Engine

For a six cylinder 3 magnets are required in total, positioned exactly 120

° apart.

Figure 2: Typical 6 cylinder/ 3 rotor application