Great Planes P-51D Mustang 40 Kit - GPMA0175 User Manual

Page 8

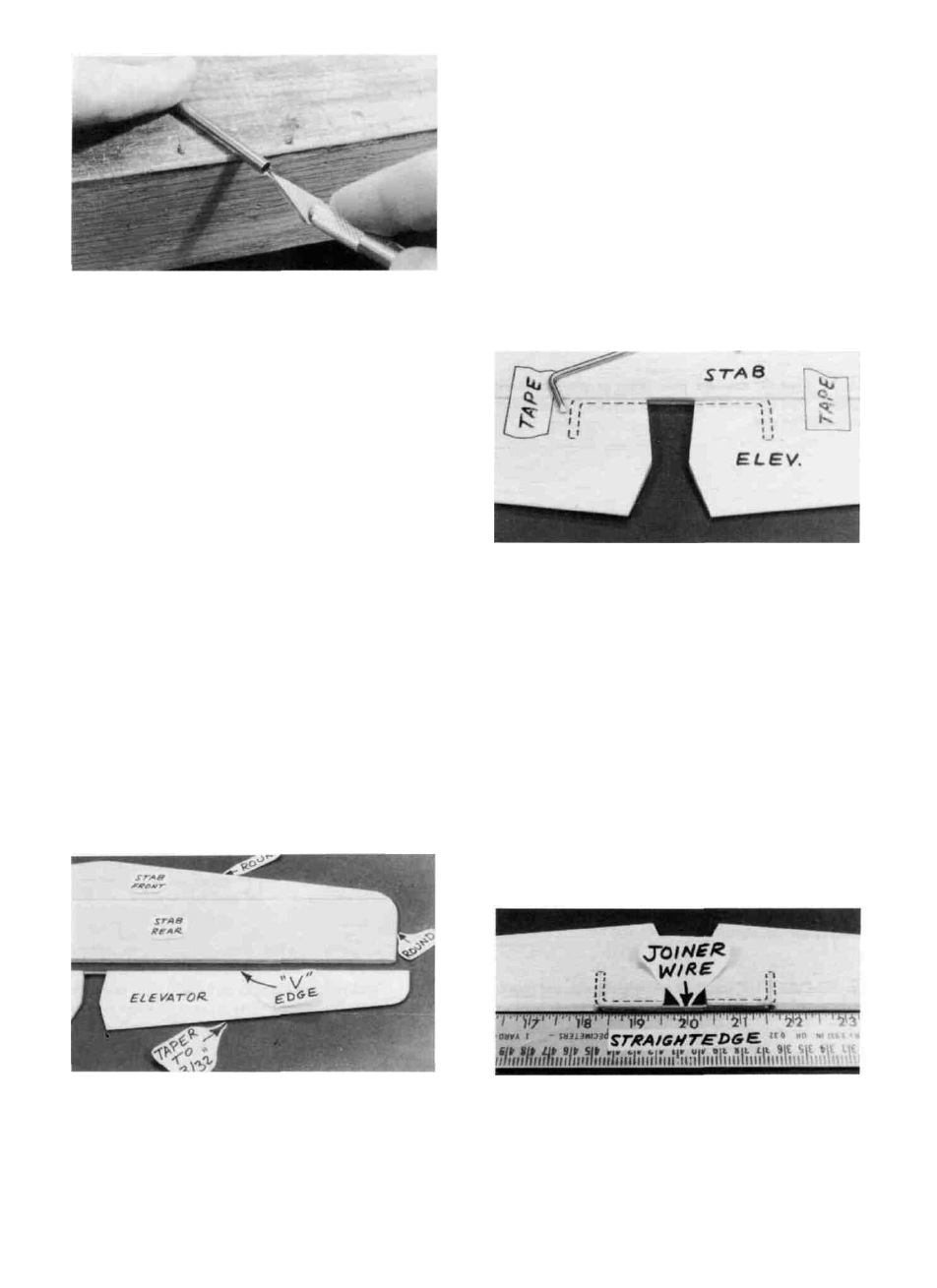

D 3. Check the shaped balsa elevators and sand if neces-

sary to match the plan.

D 4. Draw a centerline all around the edges of the stab

and elevators.

D 5. Sand both sides of the elevators to a taper as shown

on the plans. The trailing edge should end up approximately

3/32" wide and have a rounded shape (do not sand to a sharp

edge). Sand the leading edge to a "V-shape" as shown on the

plan.

D 6. Temporarily tape the elevators to the stab.

HINT: Using an Xacto knife, sharpen the inside of one

end of a 1/8" diameter brass tube, and use it to cut the groove

in the leading edge of the rudder.

*NOTE: The tailwheel location and installation shown

on the plan is designed for easy installation and durability.

and for the best possible ground handling characteristics.

However, if you are building your P-51 for sport scale

competition, you may want to install a tailgear (fixed or

retractable) in the "scale location" shown on the plan.

These instructions do not cover such a modification, but

the location is shown for your convenience.

BUILD THE STABILIZER AND

ELEVATORS

To build the stab and elevators you'll need the following:

1/4" shaped balsa stab front

1/4" shaped balsa stab rear

1/4" shaped balsa elevators

1/8" bent wire elevator joiner

D 1. Glue the stab front to the stab rear. Sand the

outline of the stab to match the plan, then sand both sides of

the stab smooth.

D 7. Lay the 1/8" wire elevator joiner in place on the

elevators and mark its outline using a fine point felt-tip pen.

D 8. Accurately drill holes in the elevators for the 1/8"

wire joiner. Begin by drilling a 1/16" or 5/64" pilot hole, then

drill the final hole to a depth of 7/8" with a 9/64" drill bit.

(The hole is drilled slightly oversize to allow for positioning,

and to create a hard epoxy "sleeve" around the wire).

D 9. Using an Xacto knife, sharpen the inside of one end

of a 1/8" diameter brass tube and use it to cut grooves in the

leading edge of the elevators to accept the joiner wire.

D 10. Roughen the joiner wire with coarse sandpaper, then

clean the wire thoroughly with alcohol to remove any oily

residue.

D 2. Sand the leading edge and ends to a rounded shape.

(Leave the center portion of the LE square).

D 11. Trial fit the joiner wire into the elevators, then glue

it in using 5-minute or 30-minute epoxy. Work plenty of

8