Great Planes P-51D Mustang 40 Kit - GPMA0175 User Manual

Page 38

D 2. Remove a sufficient portion of the W-l ribs to fit

your servo, leaving "shelves" on which to glue the 1/8" ply

rails. (See the plan to determine the depth). NOTE: A

Dremel Moto Tool with a 1/8" router bit is excellent for this,

but it may also be done with an Xacto knife and a long-nose

pliers.

D 3. Make two aileron servo rails from the 1/8" ply die-

cutting scrap, and glue them in place. (See the side view of

the aileron servo installation on the plan).

D 4. Mount the aileron servo using the screws provided

with your radio.

D 5. Screw the nylon aileron clevises approximately 2/3

of the way onto the threaded end of the two 12" steel wire

pushrods.

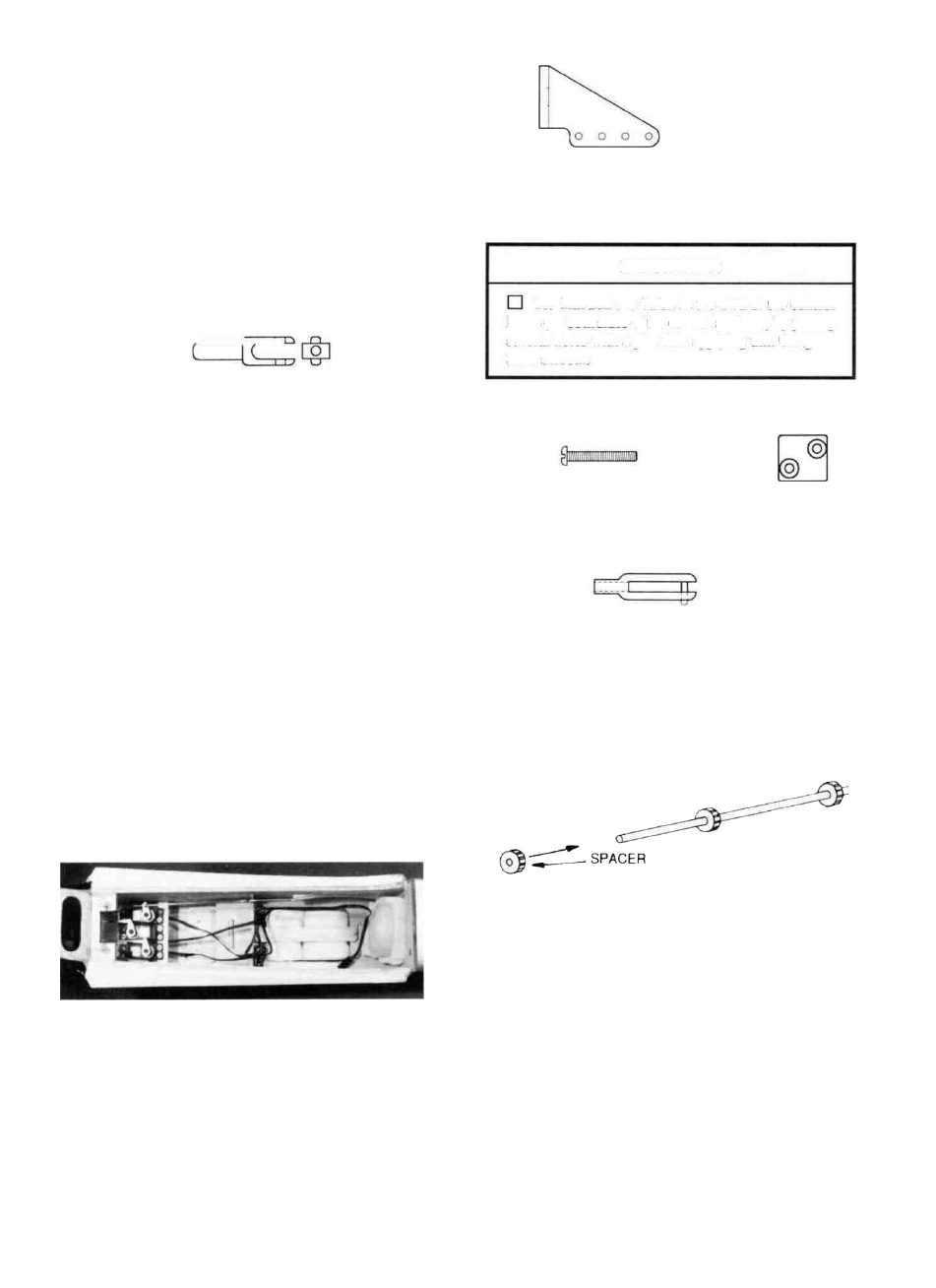

Nylon

Control Horn

D 10. Hold the nylon control horns on the elevator and

rudder in the positions shown on the plan and mark the

mounting hole locations. Drill 3/32" holes at these locations.

IMPORTANT!

D 11. Harden the balsa in the area of the control

horns (on both sides of the control surfaces) by poking

several holes with a pin, then applying thin CA glue.

Sand smooth.

NYLON AILERON CLEVIS AND CONNECTOR

D 6. Screw the nylon aileron clevis connectors onto the

aileron torque rods.

D 7. Attach the clevises to the clevis connectors, then,

with the ailerons in the neutral position, mark the pushrod

wires where they cross the holes in the servo arm. Remove the

pushrods and make a "Z-bend" in the rods at that point, using

a "Z-bend pliers" or a standard pliers.

D 8. Remove the servo wheel from the servo and work

the Z-bends into the wheel (NOTE: You may have to enlarge

the servo wheel holes with a 5/64" diameter drill bit). Replace

the servo wheel and check the operation of the ailerons. (See

page 39 for the recommended amount of aileron movement).

REMEMBER: Plan your servo installation carefully,

as your setup may differ from the plans and photos,

depending on which engine you use.

D 12. Mount the horns with 2-56 screws and the nylon

nutplates which were attached to the horns.

2-56 x 5/8

Machine Screw

Nutplate

D 13. Screw a nylon clevis onto the threaded end of each

long steel wire pushrod. NOTE; Screw them on all the way

until the threads are protruding inside the clevis.

Nylon Clevis

D 14. Cut the short length of 1/8" diameter plastic tube into

several pieces, approximately 1/4" long. Slide at least six of

these pieces onto each of the long pushrod wires and space

them approximately 2-1/2" apart (do not glue yet). NOTE:

If these tubes do not slide on easily, cut them to a shorter

length.

NOTE: While installing the pushrods, position the above

plastic tube spacers so they always stay inside the pushrod

guide tubes. If the tubes are not a tight friction fit on the

pushrod wires, apply a drop of thin CA to secure them.

D 9. Re-mount the elevator, rudder and throttle servos in

the fuselage. BUT DO NOT GLUE THE RAILS IN

PLACE! Remember, you want to maintain the ability to

move the servos if necessary for balancing. (See balancing

section later in this book).

D 15. Insert the pushrod wires into the pushrod guide

tubes (previously installed) and attach the clevises to the

elevator and rudder horns.

38