Great Planes P-51D Mustang 40 Kit - GPMA0175 User Manual

Page 15

sheeting around the LG block as necessary. IMPORTANT

NOTE: To insure a straight wing, you must pin or weight

the TE securely down on the TE jig while the bottom

sheeting is glued in place!

*As you apply the bottom LE sheeting, remember to

mark the sheeting in the exact areas of the retract mechanism,

LG wire, and wheel well locations, so you can easily find and

trim the sheeting from these areas later.

(Retracts): Trim away the sheeting in the area of the

retract and wheel well.

NOTE ON RETRACTS: Additional instructions and

photos covering installation of retracts will be found at

the end of the Wing section, on page 20.

D D 34. From the 3/32" x 1/4" x 30" balsa sticks, cut and

glue cap strips to all exposed ribs, top and bottom. HINT:

For easier positioning of the cap strips, first mark the location

of each rib on the LE and TE sheeting.

D D 35. Trim the sheeting flush with ribs W-l and W-11

and sand the entire wing panel smooth. Sand the leading edge

to smoothly blend with the LE sheeting (see note below).

IMPORTANT: The shape of the leading edge

will affect the way this airplane performs snap rolls

and spins. A blunt, rounded leading edge will

"soften" the stall, making the plane very docile

when flying slowly, enabling it to flare nose-high

for very slow landings; however, this may cause

the plane to be a little sluggish when trying to enter

a snap roll or spin. A sharper leading edge will help

the plane enter snap roll and spin maneuvers more

crisply, while sacrificing only a little of the low

speed stability. The leading edge has been

approximately pre-shaped, but we recommend

that you cut out the Leading Edge Template, and

use it as a guide when sanding the leading edge to

final shape. To avoid tip stalls, make sure the

leading edges of both wing panels have the same

shape.

D 37. Now go back and repeat Steps 9 through 36 to build

the left wing panel.

JOIN THE WING PANELS

NOTE: Read steps 1 through 4, then make a "dry run,"

practicing these steps before actually proceeding.

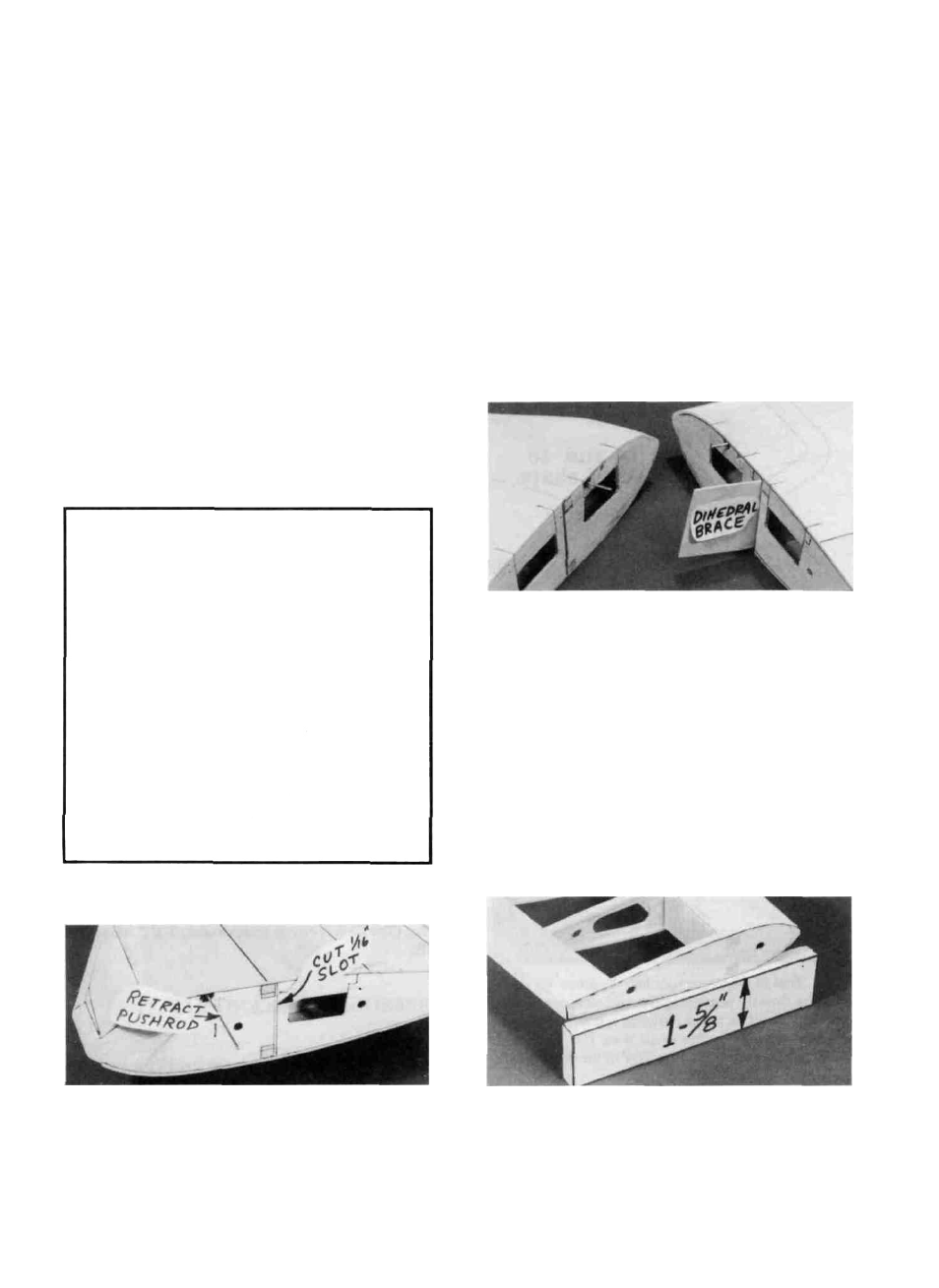

D 1. Lay a piece of waxed paper down and place the two

wing panels, right side up, so that the W-l ribs are together.

Using wood scraps, make two blocks similar to that shown in

the photo, and use them to block up both wing tips 1-5/8 inch.

Sand the wing panels at the center so they will fit together

without a gap.

D 2. Trial fit the die-cut 1/16" ply dihedral brace to

make sure it will readily slide into place.

NOTE: 30-minute epoxy is strongly recommended

for the wing joining process.

D 3. Mix up a batch of 30-minute epoxy and push some

into the dihedral brace slots. Smear epoxy on the spar ends,

and on both sides of the 1/16" ply dihedral brace. Slide the

dihedral brace in place, push the wing panels together and

immediately proceed to the next step.

D D 36. Mark and cut out a 1/16" slot in W-l just behind

the spars, for the dihedral brace.

D 4. With the wing tips blocked up 1-5/8 inch, carefully

align the LE and TE of both wing panels at the center and,

15