Great Planes P-51D Mustang 40 Kit - GPMA0175 User Manual

Page 20

D 3. Adjust the position of the L.G. covers to match the

plan. The top edge of the L.G. covers must be at least 1/4"

away from the wing, to reduce the possibility of damaging the

wing in a hard landing.

INSTALL RETRACTS (OPTIONAL)

NOTE: Hardware for retract installation is not included

in the kit.

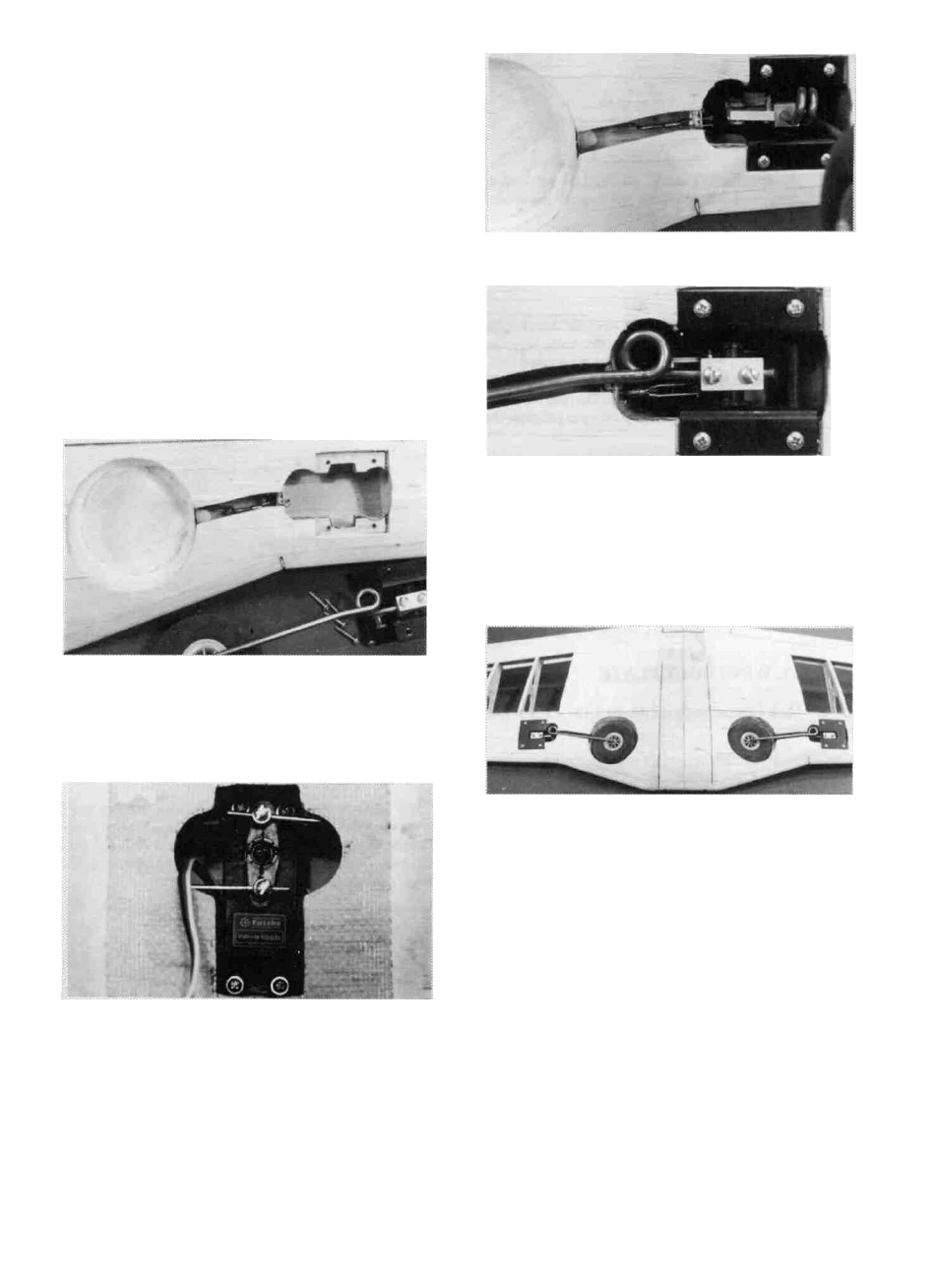

At this point most of your retract installation should

already be completed, and all that remains is to install the

retract servo and "fine tune" the installation.

D 1. If you have not already done so, cut the bottom

sheeting away in the areas of the retract mechanism, LG wire

and wheel well.

D 2. Using 1/16" or 3/32" balsa, construct a "floor" in the

wheel well, to conceal the pushrod tube, and to help seal off

the wheel well from the interior of the wing.

D 3. Cut out an opening in the top sheeting in the area of

the retract servo. Cut out a portion of the W-1 ribs to fit your

servo, and fabricate two 1/8" ply servo mounting rails in the

general area shown on the fuse plan side view. Install the

retract servo, and attach the pushrods to the servo by means

of EZ Connectors as shown.

D 4. Temporarily install all retract components. Test the

operation of your retracts making sure they operate freely and

reliably. Also make sure they "lock" in both the up and down

positions. In the retracted position, the LG wire should be just

inside the LE sheeting.

D 5. Blend the bottom sheeting as neatly as possible

around the retracts.

D 6. Add lightweight balsa filler inside the wheel well to

smooth any imperfections, and to fillet the joint between the

floor and the sides.

D 7. Use polyester resin or 30-minute epoxy thinned with

alcohol to fuelproof the entire retract area and wheel well

area.

D 8. When installing the landing gear covers (optional),

it may be necessary to add plywood shims between the L.G.

20