Great Planes P-51D Mustang 40 Kit - GPMA0175 User Manual

Page 14

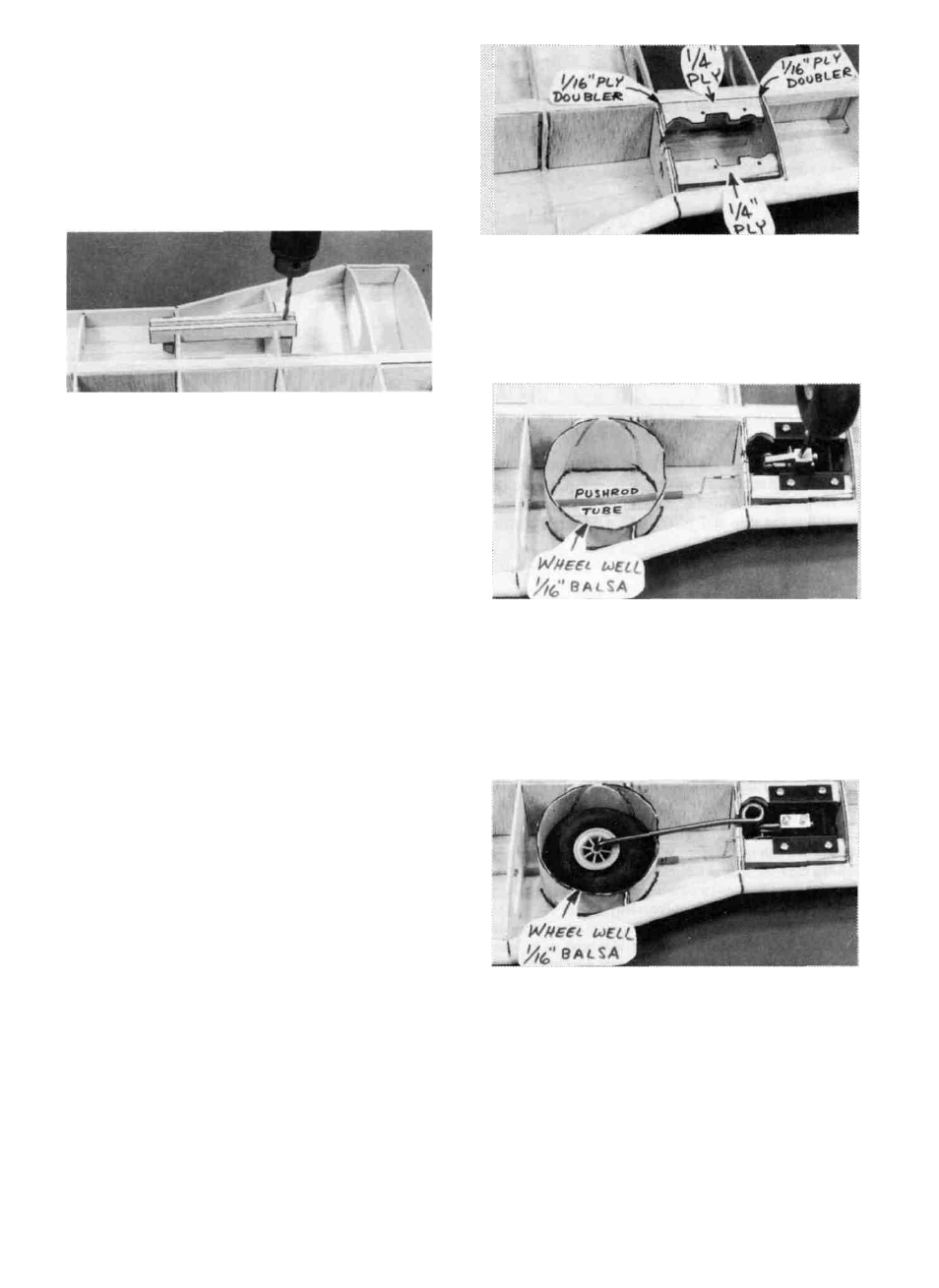

D D 29. Epoxy the 7/16" x 5/8" x 7/8" hardwood block to

the LG block and to the 1/16" ply doubler on rib W-3, as

shown on the plan and in the photo, then epoxy the small

hardwood gusset to the other end of the LG block and to the

1/16" ply doubler on rib W-4.

D D 30. Drill a 5/32" hole down through the grooved LG

block and the 7/8" block. Line up the drill so you are drilling

straight down through the middle of the 7/8" block.

D D 31. Trial fit the 5/32" diameter main landing gear

wire into the landing gear block at this time. Cut or file the

groove and hole in the landing gear block as necessary for a

good fit.

D D 32. Using a razor saw and a sanding block, carefully

cut off and sand all excess sheeting, spars, LE and TE even

with W-1 and W-11.

NOTE: If you will be installing retracts, now is the

time to install the 1/4" x 5/8" x 2-5/8" ply retract

mounting rails with epoxy on the bottom of the wing

between the 1/16" ply doublers on ribs W-4 and W-5, as

shown on the plan. Add 1/4" balsa triangle under the

1/4" ply rails. Installing retracts requires careful

planning and a lot of trial Fitting, customizing the

installation as necessary to accommodate your retracts;

therefore, you should take the time now to plan out your

installation. Here are some typical tasks you must

perform when installing retracts:

NOTE: All photos in this book show installation of the

Dave Brown mechanical retracts.

C. Gluo in 1/4" ply retract mounting; rails using

epoxy.

D. Trim the rails as necessary.

E. Install pushrod and guide tube just under the top

sheeting.

F. Fabricate wheel well from 1/16** balsa or styro-

foam cup.

A. Glue in the 1/16" ply nose rib doublers to reinforce

ribs W-4 and W-5 where retracts are to be installed.

B. Trial fit the retract unit to determine the mounting

location and angles. Cut away the ribs as necessary for

clearance.

G. Install retract unit and check operation.

H. Sheet bottom of wing, taking note where sheeting

will be cut away for retract.

D D 33. With the wing upside down, again use the TE jig

to support the TE. Then install the bottom TE sheeting, LE

sheeting* and Center Section sheeting, cutting and fitting the

14