English – KEYENCE SL-C Series User Manual

Page 48

Chapter 4 Checklist

4

English

ENGLISH

2. Check Using an Operation Test with the Machine Stopped

With the machine stopped, turn on the power of the SL-C and carry out the following tests using the

test piece included in the package. If you are using any of models SL-C**L having the detection

capability of 45 mm diameter, prepare a test piece having a diameter of 45 mm separately, and imple-

ment the test. If the floating blanking function is active, do not use the attached test piece, but use a

proper test piece that conforms to the description given in the SL-R12EX manual.

❏

When the power of the SL-C is turned on with no test piece in the detection zone, the output status

indicator as well as bar LEDs turn green.

❏

Confirm that the status indicator (bar LED) on the SL-C turns red and maintains red state while the

test piece is present within the detection zone.

❏

The test piece can be detected regardless of its location as long as it is in the detection zone.

❏

If the SL-R11(E) restart interlock function is enabled, when the test piece is removed, confirm

that the bar LEDs on the SL-C light up green, the output status indicator lights up red, and the

SL-R11(E) interlock indicator lights up yellow.

❏

When in the restart interlock state, the start/restart input causes the output status indicator to

change to green, and the SL-R11(E) interlock indicator to turn off.

❏

If the SL-R11(E) start interlock function is enabled, confirm that the bar LEDs lights up green, the

output status indicator lights up red, and the SL-R11(E) interlock indicator lights up yellow when the

power of the SL-C is turned on with no object in the detection zone.

❏

In addition, the output status indicator changes to green and the SL-R11(E) interlock indicator turns

off when there is a start/restart input while in the start interlock state.

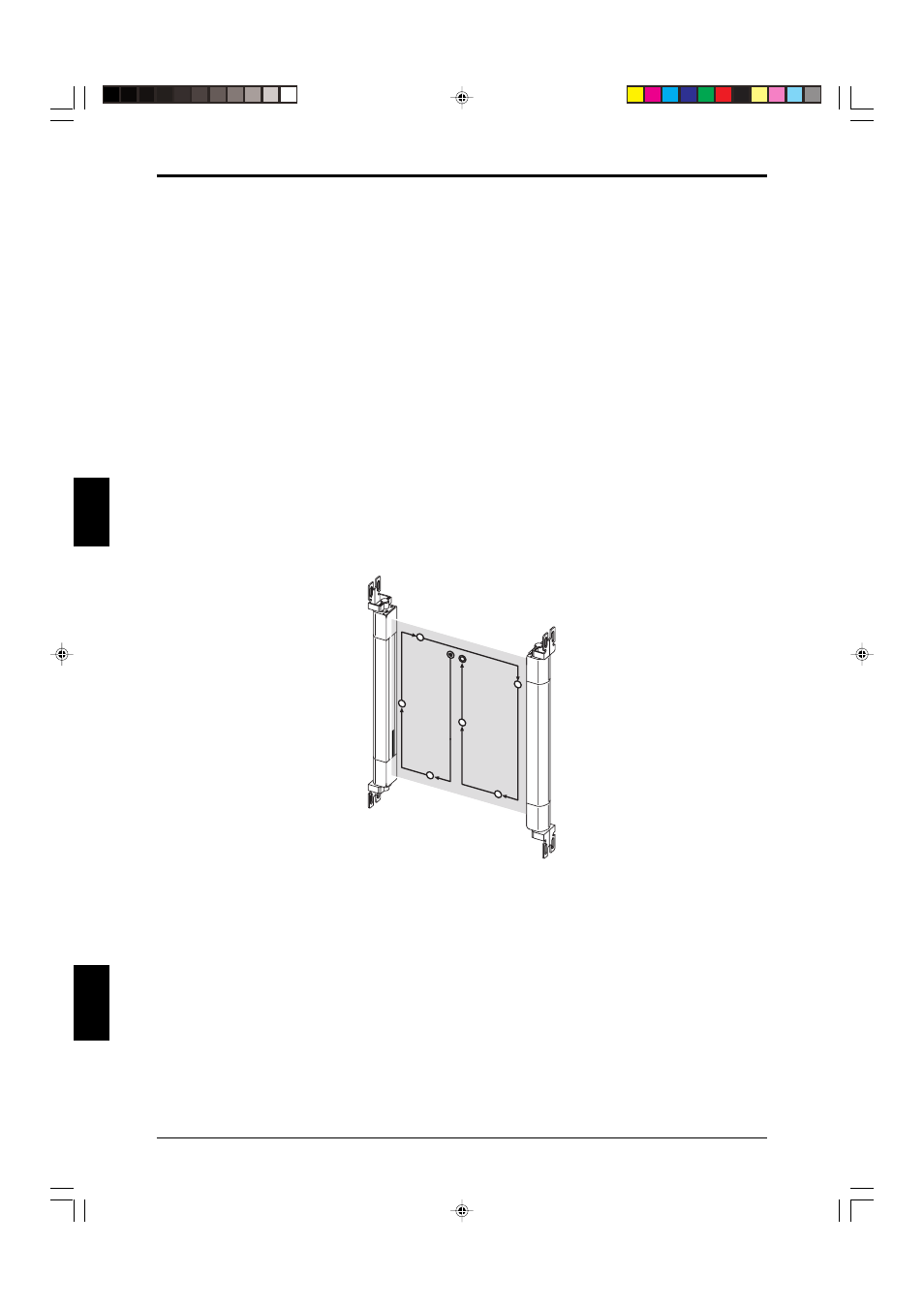

Move the test piece for detection confirmation as illustrated in the figure below.

Star

t

Stop

3. Operation Test with the Machine Operating

This test confirms that the machine stops its operation.

❏

Place the test piece in the detection zone or protection zone of the SL-C. It is recommended to try

three locations: near the transmitter, near the receiver, and the central area of the detection zone.

The machine must stop immediately as soon as the test piece is placed.

❏

The machine must remain stopped as long as the test piece is in the detection zone.

❏

The machine will not operate when the SL-C Series power supply has been interrupted.

❏

The overall response time of the machine, including the response time of the SL-C and the time it

takes for the machine to stop, must be shorter than the overall response time T used in the calcula-

tion of safety distances (

➮ See “2-2 Safety Distances” (page 2-5)).

4-4