Contact, How to replace the dust seal, Installing the air tube – KEYENCE GT2-100 Series User Manual

Page 7: How to replace the contact

7

GT2-100-M-E

● Mounting with the mounting holes

Mount the GT2-H32(L)/H50/A32/A50 on the side of a table using

the mounting holes on the side of the unit body.

■

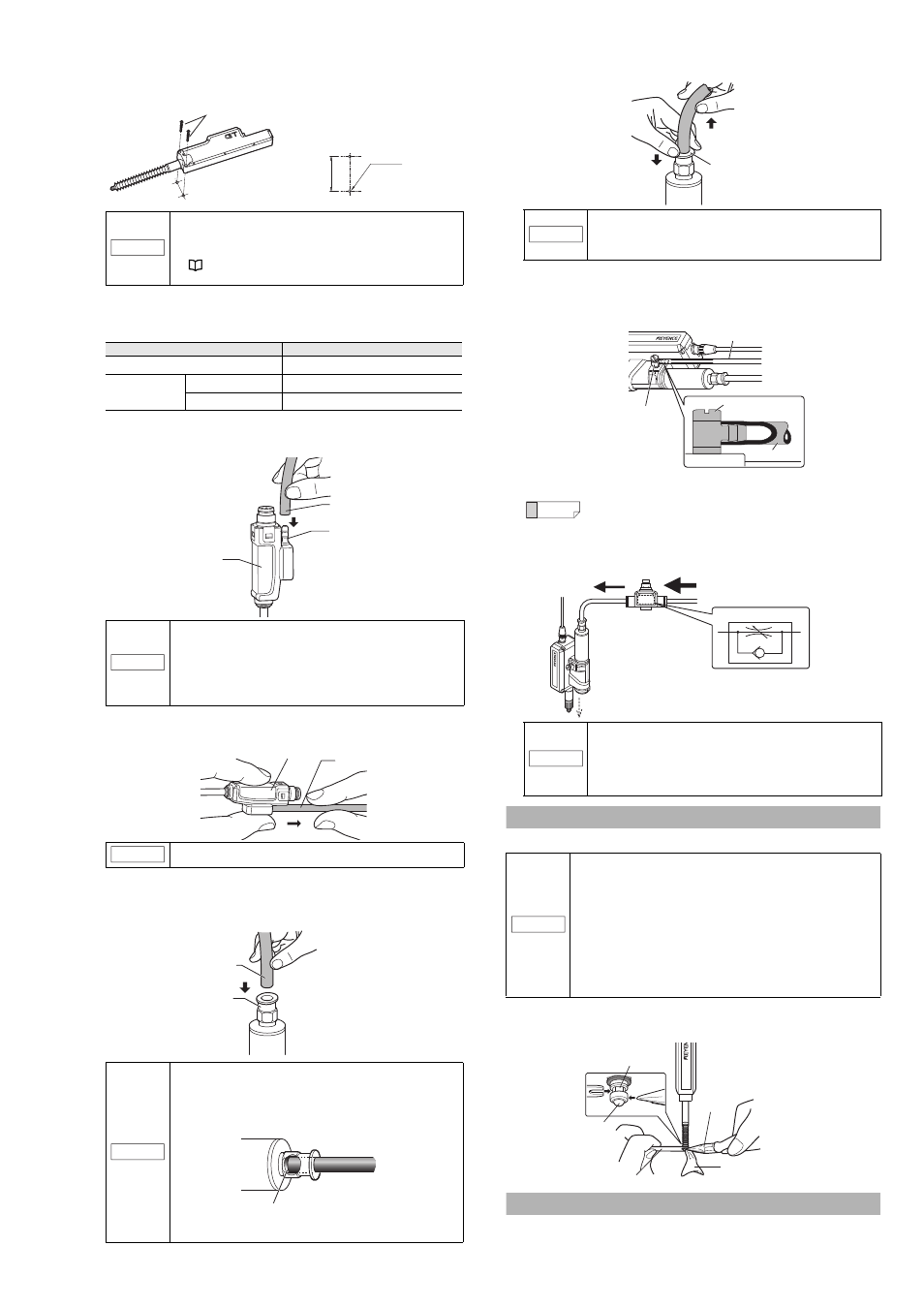

Installing the Air Tube

● Compatible air tube

Use a tube with the following specifications.

● How to Attach/Detach the Air Tube (GT2-PA12K/PA12)

•

Attaching the air tube

Insert the air tube into the air supply hole on the relay connector.

•

Detaching the air tube

To detach the air tube, pull the air tube in the direction of the arrow,

as indicated in the figure below.

● How to Attach/Detach the Air Tube (GT2-A12K(L)/A12(L)/A32/A50)

•

Attaching the air tube

Feed the tubing into the socket until it bottoms out (about 1/2").

The socket will ensure a tight seal around the tubing.

•

Detaching the air tube

To detach the air tube, (1) press down on the release ring, (2) pull out the tube.

● For GT2-A12K/A12/A32/A50 when an IP67 enclosure rating is required

To maintain an IP67 enclosure rating, the following must be satisfied:

•

Firmly connect tubing with

2.5 mm inner diameter to the exhaust

port until it bottoms out.

Ensure that the tube end is free of dirt or water.

•

Tighten the screw of the exhaust valve with a torque of 0.5 to 0.6 N•m.

If the screw is loose, the IP67 rating cannot be guaranteed.

● Adjustment of Spindle Movement Speed

To adjust the spindle movement speed, install a speed controller between

the cylinder and the air supply. Using OP-87970 is recommended.

Contact

This section describes how to replace the contact, and how to mount the lift lever.

■

How to replace the contact

While securing the spindle with the accessory key wrench, detach the

contact with pliers. Then attach a new contact.

How to replace the dust seal

Refer to the instruction manual included with the replacement dust seal

(OP-87932).

NOTICE

• Roughness of the mounting surface may cause the

sensor to tilt, and sufficient accuracy may not be

obtained. When performing a high-accuracy

measurement, use a jig to mount the sensor head.

"Mounting directly to a jig" (Page 5)

• Apply tightening torque between 1.2 and 1.5 N•m.

Item

Description

Recommended tubing material

Urethane

Tubing size

Outer diameter

4 mm

Inner diameter

2.5 mm

NOTICE

• For best results, cut the end of the tube at a right angle,

and ensure that the outer perimeter is not damaged,

and that it still maintains a circular cross section.

• If the tube is not properly inserted, air leakage may result.

• After attaching, pull on the tube to make sure it is secure.

• Use a urethane tube. Make sure it also has a bending

radius of at least 50 mm.

NOTICE

Before detaching the tube, be sure to stop any air flow.

NOTICE

• For best results, cut the end of the tube at a right

angle, ensure that the outer perimeter is not

damaged, and that it still maintains a circular cross

section.

• If the tube is not properly inserted, air leakage may

result (see figure below).

• After attachment, pull on the tube to make sure it is

secure.

M4 screws

(Mounting hole dimensions)

Mounting diagram

23

±0.15

mm

4-M4 tap

Air tube

Air supply hole

Relay connector

Relay connector

Air tube

Air tube

Coupling socket

Tube end

NOTICE

• Before detaching the tube, be sure to stop any air flow.

• Press down on the release ring evenly from both sides, and

pull the tube out. Uneven pressure may result in damage to

the tube or damage to the operation of the air cylinder.

Reference

By loosening the screw of the exhaust valve, you can

change the exhaust port angle.

NOTICE

• To further decrease spindle movement speed, use

a coil-shaped tube (OP-87986) or similar to

increase the distance between the air supply hole

and the speed controller.

• The speed controller will not operate if installed in

the reverse direction.

NOTICE

• Detach the sensor head from the device or fixture

(metal plating, etc.) before replacing the contact.

• When applying pliers to the contact, be sure not to rotate

the main part and cover the contact with a cloth.

• Never apply tightening torque over 0.2 N•m when

attaching a contact.

• Fix the roller contact (OP-77680) or the offset contact (OP-77683)

with the fixing nut in the same direction as in actual use.

• Applying an adhesive, a thread locking agent, is

recommended to prevent the nut from loosening.

• Position the roller contact carefully in the proper direction.

Care must be taken not to apply misdirected force to the shaft.

Release ring

(2)

(1)

Screw

Air tube

Air tube

Exhaust valve

Speed controller

Air supply

Indication symbol

Adjusting the speed.

Spindle

Contact

Key wrench

Pliers

Cover the contact

with a cloth