Connecting and mounting the sensor head, Names of parts of the sensor head, Connecting the sensor head connection cable – KEYENCE GT2-100 Series User Manual

Page 5: Connecting the amplifier, Mounting the sensor head, For gt2-p***/pa, For units other than gt2-p***/pa, Mounting directly to a jig

5

GT2-100-M-E

Connecting and Mounting the Sensor Head

■

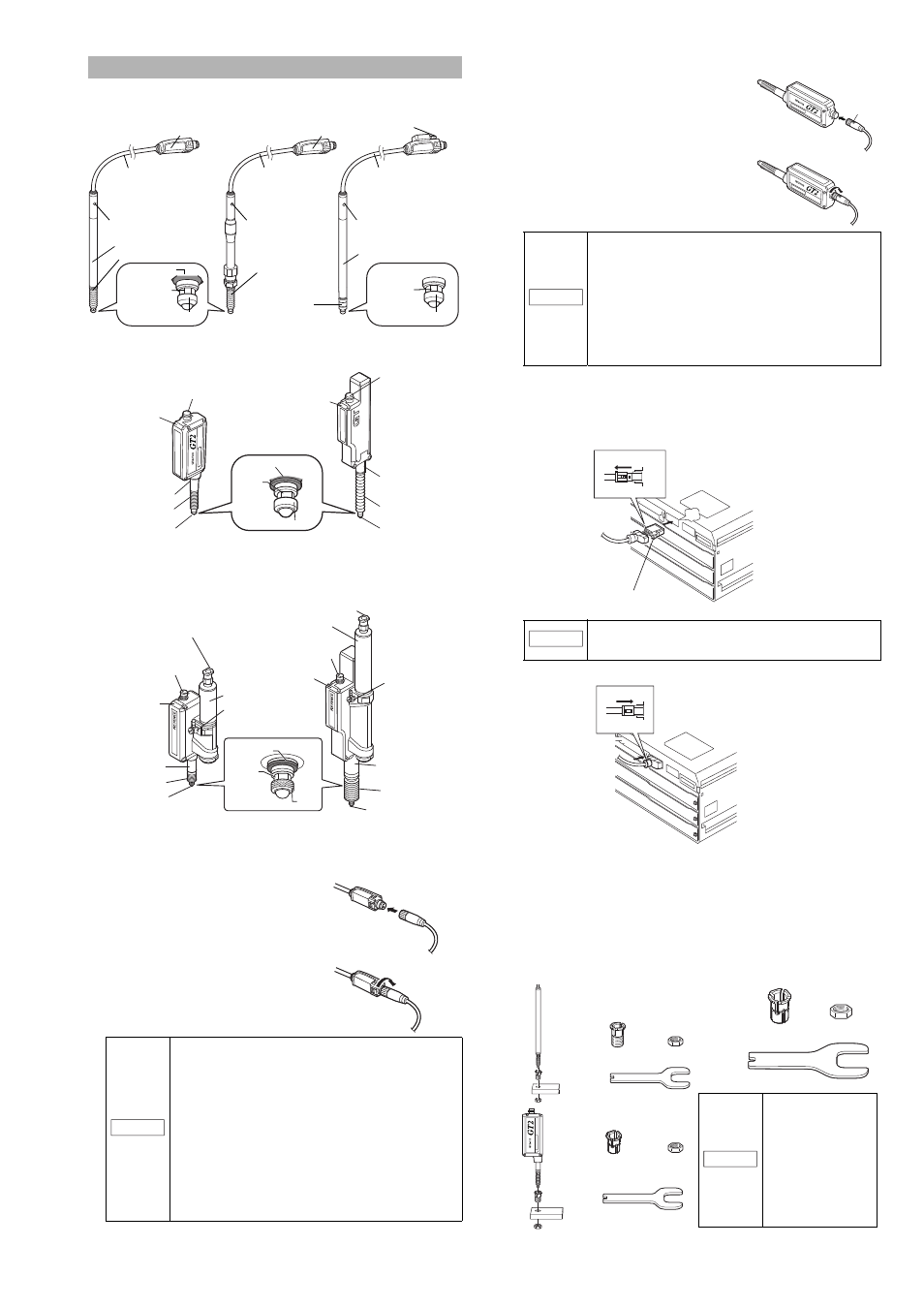

Names of parts of the sensor head

* Not included in the GT2-P12KL/P12L.

● GT2-H12K(L)(F)(LF)/H12(L)(F)(LF)/H32(L)/H50

● GT2-A12K(L)/A12(L)/A32/A50

■

Connecting the sensor head connection cable

● For GT2-P***/PA***

1

Insert the sensor head connection

cable into the cable connector on the

relay connector cable.

2

Secure the connector with the sensor

head connection cable screw.

● For units other than GT2-P***/PA***

1

Insert the sensor head connection

cable into the cable connector of the

sensor head.

2

Secure the connector by rotating the

grooved portion of the sensor head

connection cable.

• To disconnect the sensor head connection cable, reverse the steps above.

■

Connecting the amplifier

1

Remove the lock cover of the connector of the sensor head

connection cable, and insert the sensor head connection cable

into the connector on the back of the amplifier until it clicks.

2

Put the lock cover on the connector, and lock the lock cover.

■

Mounting the sensor head

● Mounting directly to a jig

Before mounting the sensor head directory to a jig, create a hole on the

jig. Attach the sensor head using the optional head mounting bracket

sold separately. A mounting bracket is provided with the GT2-P12KF/

P12F/H12K(L)F/H12(L)F as standard. Attach it with the supplied nut.

NOTICE

• When connecting the connector, be sure to insert it

straight, and tighten it securely. (Recommended

tightening torque: 0.4 to 0.5 N•m*)

If the connection is not tight enough, the connector

may be loosened by vibration or other causes,

leading to a connection failure.

(* After tightening it firmly by hand, use pliers or

other tools to rotate it about 30° for further

tightening.)

• When the head is attached to a moving part, and

the cable will be repeatedly bent, ensure that the

cable between the sensor head and relay

connector does not bend. Instead, bend the sensor

head cable connecting the relay connector and the

amplifier.

Operation indicator

Relay connector

Cable

connector

Dust boot

Mounting fixture

Dust boot

*

Spindle

Contact

Dust boot

GT2-P12K(L)/P12(L)

GT2-P12KF/P12F

Cable between

the sensor

head and relay

connector

GT2-PA12K/PA12

Relay connector

Cable

connector

Cable

connector

Cable

between the

sensor head

and relay

connector

Operation indicator

Cable between

the sensor

head and relay

connector

Mounting fixture

Operation indicator

Contact

Spindle

Air supply hole

Dust seal

*1 A mounting bracket is attached to

GT2-H12KF/H12F/H12KLF/H12LF.

*2 Not included in the GT2-H12KL/H12L/H12KLF/H12LF.

Contact

Head indicator

Head indicator

Contact

Dust boot*

3

Bracket fixing

part

Cable connector

Cable connector

Bracket fixing

part*

1

Dust boot*

2

Contact

Dust boot

Spindle

*3 Not included in the GT2-H32L.

Dust boot

Dust boot*

Dust boot

Coupling socket

Coupling socket

Air cylinder

Air cylinder

Head indicator

Head indicator

Cable connector

Cable connector

Exhaust valve

Exhaust valve

Spindle

Contact

Mounting fixture

Mounting fixture

Contact

Contact

* Not included in the GT2-A12KL/A12L.

NOTICE

• When connecting the connector, be sure to insert it

without tilt, and tighten it securely. (Recommended

tightening torque: 0.4 to 0.5 N•m*)

If the connection is not tight enough, the connector

may be loosened by vibration or other causes,

leading to a connection failure.

(* After tightening it strongly by hand, use pliers or

other tools to rotate it about 30° for further

tightening.)

• The M8 L-shaped connector (GT2-CHL*M) cannot

be used with the GT2-H32(L)/H50/A32/A50.

NOTICE

To disconnect the sensor head connection cable,

press and hold the lock lever on the side of the

connecter and disconnect the cable.

Arrow

click

Lock cover

Unlocked

Orient the connector so that the lock lever is on the right side.

Lock cover

Locked

Tightening sleeve

Key wrench

Nut

Options of the head mounting

bracket A (OP-76874)

Tightening sleeve

Key wrench

Nut

Options of the head mounting

bracket D (OP-84327)

Tightening sleeve

Key wrench

Nut

Options of the head mounting

bracket C (OP-84396)

● GT2-P12K(L)/P12(L)/PA12K/PA12/

H12K(L)/H12(L)/A12K(L)/A12(L)

● GT2-H32(L)/H50/A32/A50

NOTICE

When mounting the

GT2-H32L facing

upward, be sure to

use the mounting

holes on the side of

the sensor head. If

the sensor head is

mounted using head

mounting bracket D,

the spindle may not

fully extend.

Mounting

illustration