Using mounting bracket f, Mounting on the side of a surface – KEYENCE GT2-100 Series User Manual

Page 6

6

GT2-100-M-E

1

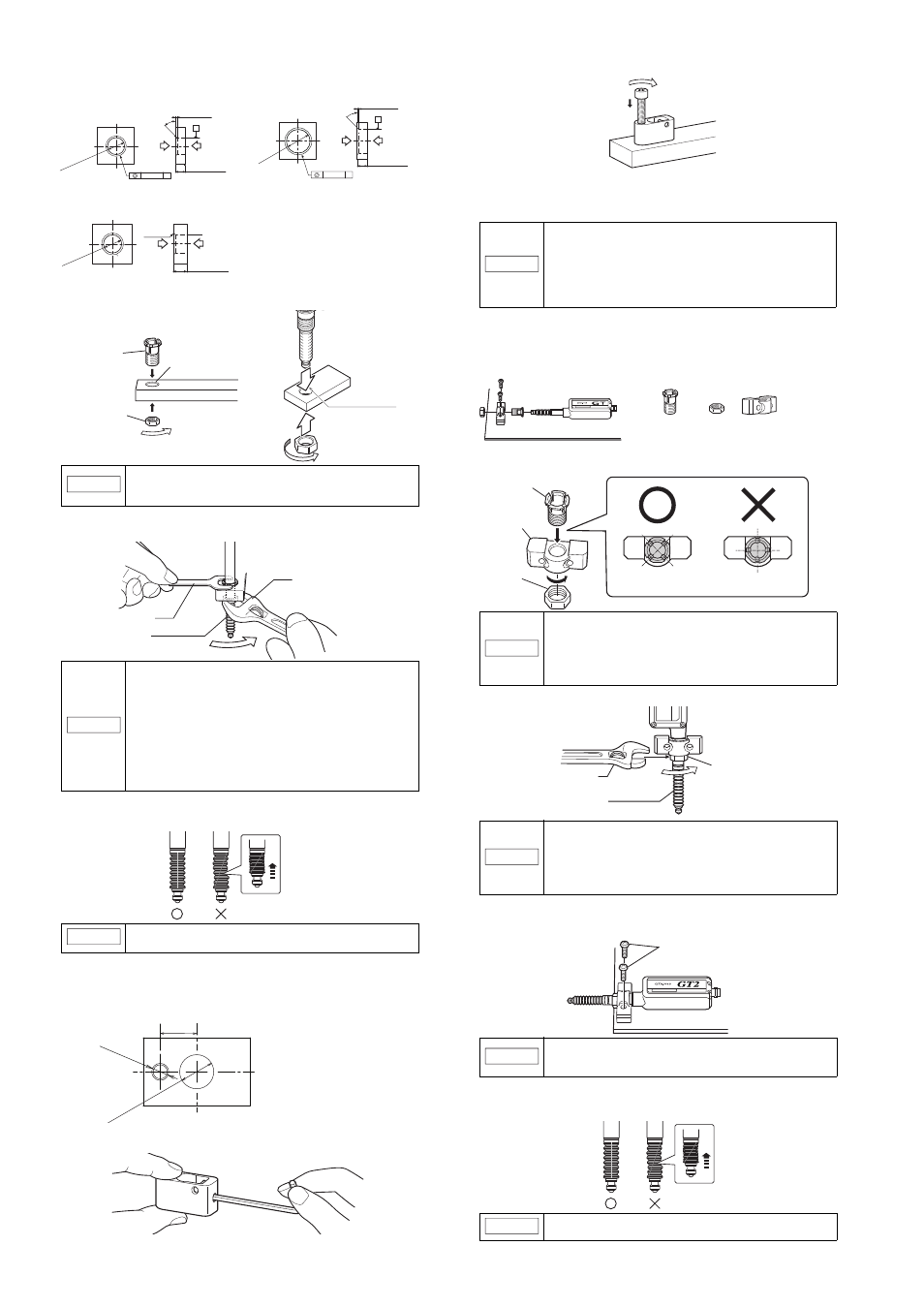

Cut the jig to create a sensor head mounting hole referring to

the illustration below.

2

Insert the tightening sleeve into the hole (from the Chamfered

side), and loosely tighten with the nut.

3

Insert the sensor head in the tightening sleeve. While securing the tightening

sleeve with the included key wrench, tighten the nut with a separate wrench.

4

Rotate the dust boot so that the side line is straight. (Models

other than GT2-PA12K/PA12)

Check with the spindle pushed in.

● Using mounting bracket F

1

Refer to the illustration below and cut the jig to create a sensor head

mounting hole.

2

Loosen the screw on the side of mounting bracket F using the

supplied hexagonal wrench.

3

Align mounting bracket F with the hole made in step 1 and

secure it using the supplied hexagonal wrench.

4

Insert the sensor head, and tighten the screw loosened in step 2 using

the supplied hexagonal wrench to secure. The recommended

tightening torque is 0.6 to 0.8 N•m. Make sure that the dust boot does

not obstruct the metal plating that mounting bracket F is attached to.

● Mounting on the side of a surface

When mounting to the side of a GT2-P12K(L)/P12(L)/PA12K/PA12/H12K(L)/

H12(L)/A12K(L)/A12(L) unit, use the optional head mounting bracket B (OP-

76875).

1

Insert the tightening sleeve into the mounting bracket from the

side with a depression, and loosely tighten with the nut.

2

Insert the sensor head into the tightening sleeve, and tighten the nut with a wrench.

3

Secure the sensor head with M4 screws.

Mount the sensor head with the model label on top. For GT2-P12K(L)/

P12(L)/PA12K/PA12, mount so that the head indicator is on top.

4

Rotate the dust boot so that the side line is straight. (Models

other than GT2-PA12K/PA12)

Check with the spindle pushed in.

NOTICE

In the illustration on the left above, if the nut is fully

tightened when the sensor head is not yet inserted,

the fixture will become deformed.

NOTICE

Tightening the nut while fixing the sensor head may lead to damage.

• The tightening torque for mounting bracket A (OP-

76874), mounting bracket C (OP-84396), and the

nuts supplied with GT2-H12K(L)F/H12(L)F/P12KF/

P12F is between 5 and 7 N•m (the recommended

tightening torque is 5 N•m). Apply tightening torque

between 15 and 18 N•m (20 to 23 N•m when using

the GT2-A32/A50) to head mounting bracket D (OP-

84327). Use the wrench that matches the nut width.

• Care must be taken not to damage the dust boot

when tightening.

NOTICE

If the dust boot is not straight, it becomes easier to

damage when the spindle is moved.

● GT2-P12K(L)/P12(L)/PA12K/PA12/

H12K(L)/H12(L)/A12K(L)/A12(L)

● GT2-H32(L)/H50/A32/A50

φ10

+0.005

+0.1

Nut

mounting

side

*1 For head mounting bracket C *2 Processing accuracy : ±0.05

φ10 G8

( )

*1

+0.005

+0.027

0.5 to 1.0

*2

5.5 to 11.3

*2

A

45°

±1°

φ0.025 A

(Unit: mm)

Tightening

sleeve

insertion

side

φ14

+0.1

+0.006

0.5 to 1.0

*2

5.5 to 11.3

*2

45°

±1°

φ0.025 A

(Unit: mm)

Nut

mounting

side

Tightening

sleeve

insertion

side

φ10

+0.005

+0.1

0.5 × 45°

recession

5.5 to 11

Nut

mounting

side

Sensor head

insertion side

(Unit: mm)

● GT2-P12KF/P12F/H12K(L)F/H12(L)F

Tightening sleeve

Nut

Chamfered side

Sensor head

Chamfered side

Nut

Key wrench

Dust boot

Wrench

8.5

8

+0

.20

0

+0

.00

5

M4 x

0.7

Make sure that the metal plating

mounting bracket F attaches to is made

of SUS (SUS303 recommended) and is

at least 5 mm thick.

•

GT2-P12K(L)/P12(L)/PA12K/PA12

NOTICE

• Make sure that the dust boot does not become

damaged during the procedure.

• When loosening the screw with the hexagonal wrench,

insert the long end of the hexagonal wrench into the

hex screw and rotate the small end with your hand.

• Do not forcibly tighten the hex screw.

• Cannot be used with GT2-P12KF/P12F/H***/A***.

NOTICE

• If the sleeve is inserted from the wrong side, the

sensor head cannot be secured.

• Strongly tightening the nut without the sensor head

inserted may deform the tightening nut.

• Head mounting bracket C (OP-84396) and head mounting

bracket D (OP-84327) cannot be used together.

NOTICE

Tightening the nut while fixing the sensor head may

lead to damage.

• Apply a tightening torque of 5 to 7 N•m (the

recommended tightening torque is 5 N•m).

Use the wrench that fits the width of the nut.

• Care must be taken not to damage the dust boot when tightening.

NOTICE

• Never apply tightening torque over 1.4 N•m.

• Care must be taken not to damage the dust boot

when tightening.

NOTICE

If the dust boot is not straight, it becomes easier to

damage when the spindle is moved.

Mounting illustration

Tightening sleeve

Nut

Mounting bracket

Options of the head mounting

bracket B (OP-76875)

Tightening sleeve

Mounting bracket

Nut

Notice the correct angle of the tightening sleeve.

Nut

Wrench

Dust boot

M4 screws