Specifications, Sensor head, Box type – KEYENCE GT2-100 Series User Manual

Page 14: Air cylinder type, Gt2-100-m-e

14

GT2-100-M-E

Specifications

■

Sensor head

GT2-P***/PA*** cannot be connected to amplifier units purchased before April 15th 2014.

● Pencil type (GT2-PA12K/PA12 are air cylinder types)

*1

When the surrounding temperature is 20°C.

*2

This is a typical value at the center of the measuring range. The measuring force varies depending on the mounted condition of the dust boot.

For GT2-PA12K/PA12, this is a representative value when using 0.25 MPa. The measuring force varies depending on the air pressure used. See table 1 for more details.

There is no dust boot for GT2-PA12K/PA12.

*3

When using an M8 oil resistant cable (GT2-CHP2M/5M/10M) as the sensor head cable.

*4

The contact is a separately sold option.

*5

Including the relay connector.

Note: Cannot be used with amplifier units purchased before April 15th, 2014.

● Box type

*1

When the surrounding temperature is 20°C.

*2

This is a typical value at the center of the measuring range. The measuring force varies depending on the mounted condition of the dust boot.

*3

The contact is a separately sold option.

● Air cylinder type

*1

When the surrounding temperature is 20°C.

*2

This is a typical value at the center of the measuring range. The measuring force varies depending on the mounted condition of the dust boot.

*3

Connect an air tube to the exhaust valve so that no foreign materials enter from the valve.

*4

When using mounting bracket D (OP-84327) with GT2-A32/A50, vibration is 0.75 mm.

*5

The contact is a separately sold option.

Model

GT2-P12K

GT2-P12KF

GT2-P12KL

GT2-P12

GT2-P12F

GT2-P12L

GT2-PA12K

GT2-PA12

Detection system

Scale shot system II Absolute type (without tracking error)

Measuring range

12 mm

Resolution

0.1 µm

0.5 µm

0.1 µm

0.5 µm

Indication accuracy

*1

1 µm (P-P)

2 µm (P-P)

1 µm (P-P)

2 µm (P-P)

Measuring force

*2

When installed facing down

1.0 N

0.2 N

1.0 N

0.2 N

1.2 N

When installed sideways

0.95 N

0.15 N

0.95 N

0.15 N

1.15 N

When installed facing up

0.9 N

0.1 N

0.9 N

0.1 N

1.1 N

Sampling interval

4 ms

Mechanical response

*1

10 Hz

4 Hz

10 Hz

4 Hz

-

Pressure range

-

0.24 to 0.26 MPa

Max. pressure

-

0.5 MPa

Fluid to use

-

Clean dry air

Operation indicator

2-color LED (red, green)

Environmental

resistance

Enclosure rating

IP67G (JIS)

*3

IP67 (IEC)

NEMA Type 13

*3

-

IP67G (JIS)

*3

IP67 (IEC)

NEMA Type 13

*3

-

IP67(IEC)

Surrounding air temperature

-10 to +55°C (No freezing)

0 to +55°C (No freezing)

Relative humidity

35 to 85% RH (No condensation)

Vibration resistance

10 to 55 Hz, Compound amplitude 1.5 mm, 2 hours each in X, Y, and Z axis

Shock resistance

1000 m/s

2

(IEC60068-2-27)

Material

Main unit

Main unit cover: SUS303, Spindle for GT2-PA12K/PA12: SUS430 (Fluorine-based coating), Indicator: PET, Sensor head - Connection cable: PUR, Connector: PBT,

Dust seal (GT2-PA12K/PA12 only): SUS303/SU304/aluminium (alumite treated)/special polyester fiber

Dust boot

NBR

-

NBR

-

Contact point

*4

SUS304, tungsten carbide

SUS304, SUS440C

SUS304,

tungsten carbide

SUS304,

SUS440C

Head cable

Sold separately (connected to relay connector)

Weight (excluding cable)

*5

Approx. 35 g

Approx. 45 g

Approx. 35 g

Approx. 45 g

Approx. 35 g

Model

GT2-H12K

GT2-H12KL

GT2-H12KF

GT2-H12KLF

GT2-H12

GT2-H12L

GT2-H12F

GT2-H12LF

GT2-H32

GT2-H32L

GT2-H50

Detection system

Scale shot system II Absolute type (without tracking error)

Measuring range

12 mm

32 mm

50 mm

Resolution

0.1 µm

0.5 µm

Indication accuracy

*1

1 µm (P-P)

2 µm (P-P)

3 µm (P-P)

3.5 µm (P-P)

Measuring force

*2

When installed facing down

1.0 N

0.4 N

1.0 N

0.4 N

1.0 N

0.4 N

1.0 N

0.4 N

2.1 N

1.2 N

3.2 N

When installed sideways

0.9 N

0.3 N

0.9 N

0.3 N

0.9 N

0.3 N

0.9 N

0.3 N

1.8 N

0.9 N

2.8 N

When installed facing up

0.8 N

0.2 N

0.8 N

0.2 N

0.8 N

0.2 N

0.8 N

0.2 N

1.5 N

0.6 N

2.4 N

Sampling interval

1 ms

Mechanical response

*1

10 Hz

4 Hz

10 Hz

4 Hz

10 Hz

4 Hz

10 Hz

4 Hz

6 Hz

5 Hz

7 Hz

Operation indicator

2-color LED (red, green)

Environmental

resistance

Enclosure rating

IP67

-

IP67

-

IP67

-

IP67

-

IP67

-

IP67

Surrounding air temperature

-10 to +55°C (No freezing)

Relative humidity

35 to 85% RH (No condensation)

Vibration resistance

10 to 55 Hz, Compound amplitude 1.5 mm, 2 hours each in X, Y, and Z axis

Shock resistance

1000 m/s

2

(IEC60068-2-27)

Material

Main unit

Main unit cover: zinc die-cast, Indicator: polyarylate (PAR)

Dust boot

NBR

-

NBR

-

NBR

-

NBR

-

NBR

-

NBR

Contact point

*3

SUS304, tungsten carbide

SUS304, SUS440C

Cable

Sold separately (connected to M8 connector)

Weight (excluding cable)

Approx. 95 g Approx. 95 g Approx. 100 g Approx. 100 g Approx. 95 g Approx. 95 g Approx. 100 g Approx. 100 g

Approx. 270 g

Approx. 320 g

Model

GT2-A12K

GT2-A12KL

GT2-A12

GT2-A12L

GT2-A32

GT2-A50

Detection system

Scale shot system II Absolute type (without tracking error)

Measuring range

12 mm

32 mm

50 mm

Resolution

0.1 µm

0.5 µm

Indication accuracy

*1

1 µm (P-P)

2 µm (P-P)

3 µm (P-P)

3.5 µm (P-P)

Measuring force

*2

When installed facing down

1.2 N

0.4 N

1.2 N

0.4 N

2.1 N

3.2 N

When installed sideways

1.1 N

0.3 N

1.1 N

0.3 N

1.8 N

2.8 N

When installed facing up

1.0 N

0.2 N

1.0 N

0.2 N

1.5 N

2.4 N

Sampling interval

1 ms

Operation indicator

2-color LED (red, green)

Pressure range

0.25 to 0.5 MPa

Max. pressure

1.0 MPa

Fluid to use

Dry air

Environmental

resistance

Enclosure rating

IP67

*3

-

IP67

*3

-

IP67

*3

Surrounding air temperature

0 to +55°C (No freezing)

Relative humidity

35 to 85% RH (No condensation)

Vibration

*4

10 to 55 Hz, Compound amplitude 1.5 mm, 2 hours each in X, Y, and Z axis

Shock resistance

1000 m/s

2

(IEC60068-2-27)

-

Material

Main unit

Main unit cover: zinc die-cast, Cylinder: aluminum alloy, Air coupling socket (resin part): polyacetal, Air coupling socket (metal part): nickel plated brass, Indicator: polyarylate (PAR)

Dust boot

FKM

-

NBR

-

NBR

Contact point

*5

SUS304, tungsten carbide

SUS304, SUS440C

SUS304, SUS440C

Sensor head cable

Sold separately (connected to M8 connector)

Weight (excluding sensor head cable)

Approx. 145 g

Approx. 340 g

Approx. 405 g

0

1

2

3

4

5

6

7

8

9

10

11

12

Measuring force (N)

Spindle retracted

Spindle extended

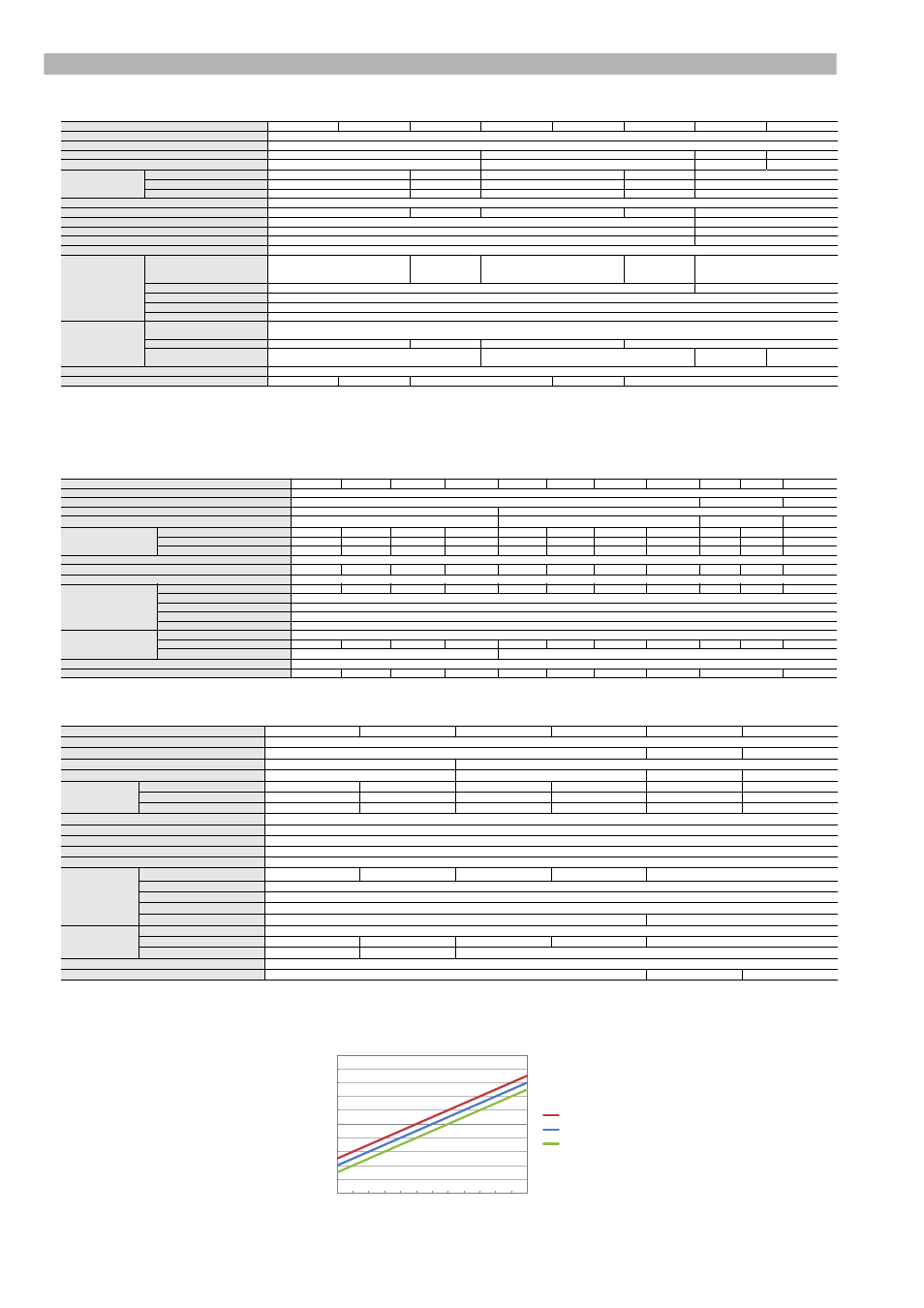

Table 1. Relationship between spindle position and measuring force grouped according to used air pressure.

(When installing side mounting, the measuring force is -0.05 N. When installing upward mounting, the measuring force is -0.1 N.)

Spindle position (mm)

Applied pressure (MPa)

1.7

1.2

0.26 MPa

0.25 MPa

0.24 MPa

0.7