Interference protection function, Keylock, Power-save (eco mode) – KEYENCE LV-SB User Manual

Page 10: Caution on a lustrous workpiece (lvs31), Error indication

10

E LV-S-IM

Interference Protection Function

The LV-S Series can prevent mutual interference by connecting amplifier units.

■ When using a model other than LV-S31

■ When using the LV-S31

Keylock

You can lock the operation buttons to prevent the settings from being

changed by careless operation of the buttons.

Setting operations for sensitivity or modes are disabled during keylock, but

the display can be switched.

•

The same steps can be taken to deactivate keylock.

Power-save (Eco Mode)

The numerical display disappears, and the current consumption is reduced.

If a key operation is performed during the Eco mode, the display returns to

normal. If no more key operation is performed for 4 seconds, the display

returns to the Eco mode.

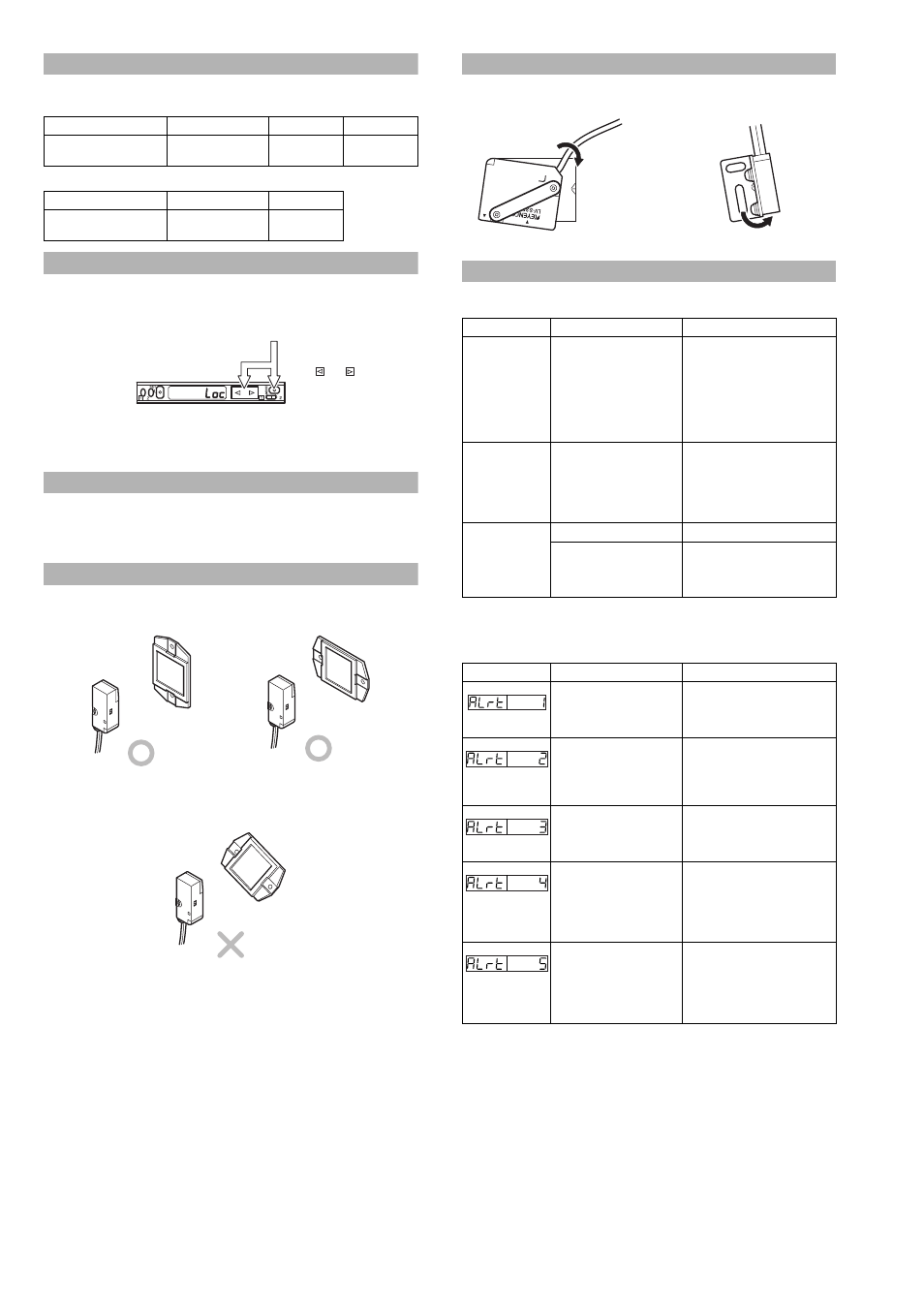

Cautions on Installing the Reflector (LV-S61/S62/S63)

Be sure to install the reflector so that it is vertical or horizontal against the sen-

sor unit.

If the reflector is installed diagonally against the sensor unit, the received light

intensity will decrease significantly.

Caution on a lustrous workpiece (LVS31)

If the workpiece is lustrous, the trimmer adjustment may not succeed or

detection may be unstable. In such a case, install the sensor slightly tilted.

Error Indication

The following indications on the LCD display show the error events. Correct

the problem using the following countermeasures.

The following table shows the alarms when "Auto" is selected for the operation

of control output "2"and channel setting is switched to "2". Refer to the follow-

ing table to remedy the alarms.

Power mode

HSP (HIGH SPEED)

FINE/TURBO

SUPER/ULTRA

Number of units required to

prevent interference

Unavailable

2 units

4 units

Power mode

HSP (HIGH SPEED)

STD

Number of units required to

prevent interference

2 units

4 units

While pressing the

MODE button, press

the

or

button for

at least three seconds.

The indicator shows that key-

lock is activated.

Error indication

Cause

Remedy

ErH

Sensor head is not

connected.

Head cable is broken.

•

Check that the sensor head is

connected.

•

Check that the head cable is

not broken.

•

Check the connection of the

head cable to the connector.

•

After checking these points,

turn on the power again.

ErC

Overcurrent flows through

the output wire.

•

Check the load and reduce

the current to be within the

rated range.

•

Check that the output wire

does not touch another wire or

a frame.

ErE

Data write/read error

•

Perform initialization.

Data has been written in

the EEPROM more than

one million times and can

no longer be updated.

•

If you need to write more data,

replace the amplifier unit.

Display

Alarm contents

Remedy

Over DSC correction limit:

Received light intensity

during OFF exceeds the

DSC correction limit.

Change the setup conditions or

replace the sensor, and secure

the correct received light

intensity during OFF.

DSC small fluctuation

detection:

There are fluctuations

within the range for the

alarm output level (rtio).

Move the workpiece to the

correct position.

Invalid DSC EEPROM

contents:

Failed to write data to

EEPROM.

Restart the power or initialize.

Over fluctuation width during

zero datum calibration:

The fluctuations of

received light intensity

during calibration are too

large.

Take anti-vibration measures in

order to suppress fluctuations

during calibration.

DSC speed limit alarm:

The received light intensity

fluctuated a large amount

in a short period of time.

•

Move the workpiece to the

correct position.

•

Take anti-vibration measures

in order to suppress

fluctuations in the received

light intensity.