Vernier LabPro User Manual

Page 55

Revision Date: 08/02/02

LabPro Technical Manual

55

To illustrate it’s use, LabPro will be programmed to count pulses for five, one-second intervals while a

super pulley spins down (the spokes block the photogate beam.)

Host

LabPro

s{1,1,14}

s{12,41,5}

s{3,1,6,0}

s{12,41,0}

{ +5.00000E+00 }

s{12,41,-1,0}

{ +5.90000E+01, +4.80000E+01, +3.70000E+01, +2.70000E+01, +1.90000E+01, }

Example 6: Rotary Motion Mode using the command {12,41,6,scalefactor}

Host

LabPro

s{1,1,14}

s{12,41,6,1}

s{3,1,10,0}

s{12,41,0}

{ +1.00000E+01 }

s{12,41,-1,0}

{ -3.36000E+02, -3.31500E+03, -5.63200E+03, -7.38700E+03, -8.67000E+03, -

9.57900E+03, -1.01930E+04, -1.05800E+04, -1.07980E+04, -1.08850E+04, }

s{3,-1}

s{12,41,-1,0}

{ +1.10000E+01, +1.14000E+02, +2.06000E+02, +2.92000E+02, +3.72000E+02,

+4.42000E+02, +5.00000E+02, +5.47000E+02, +5.87000E+02, +6.24000E+02, }

s{12,42,6,0}

s{3,-1}

s{12,42,-1,0}

{ -2.10000E+01, -2.09000E+02, -3.89000E+02, -5.58000E+02, -7.21000E+02, -8.7200

0E+02, -1.01700E+03, -1.15100E+03, -1.27600E+03, -1.39500E+03, }

This mode is designed to measure the position of a rotary motion sensor. Rotational motion information is

determined by counting clockwise and counterclockwise signals from the Vernier Rotary Motion Sensor as

shown in Figure 6. The resolution of the rotary motion sensor can be set to high or low where low

resolution is one-fourth that of high resolution. This is chosen by setting the P1 parameter to 1 or 0,

respectively.

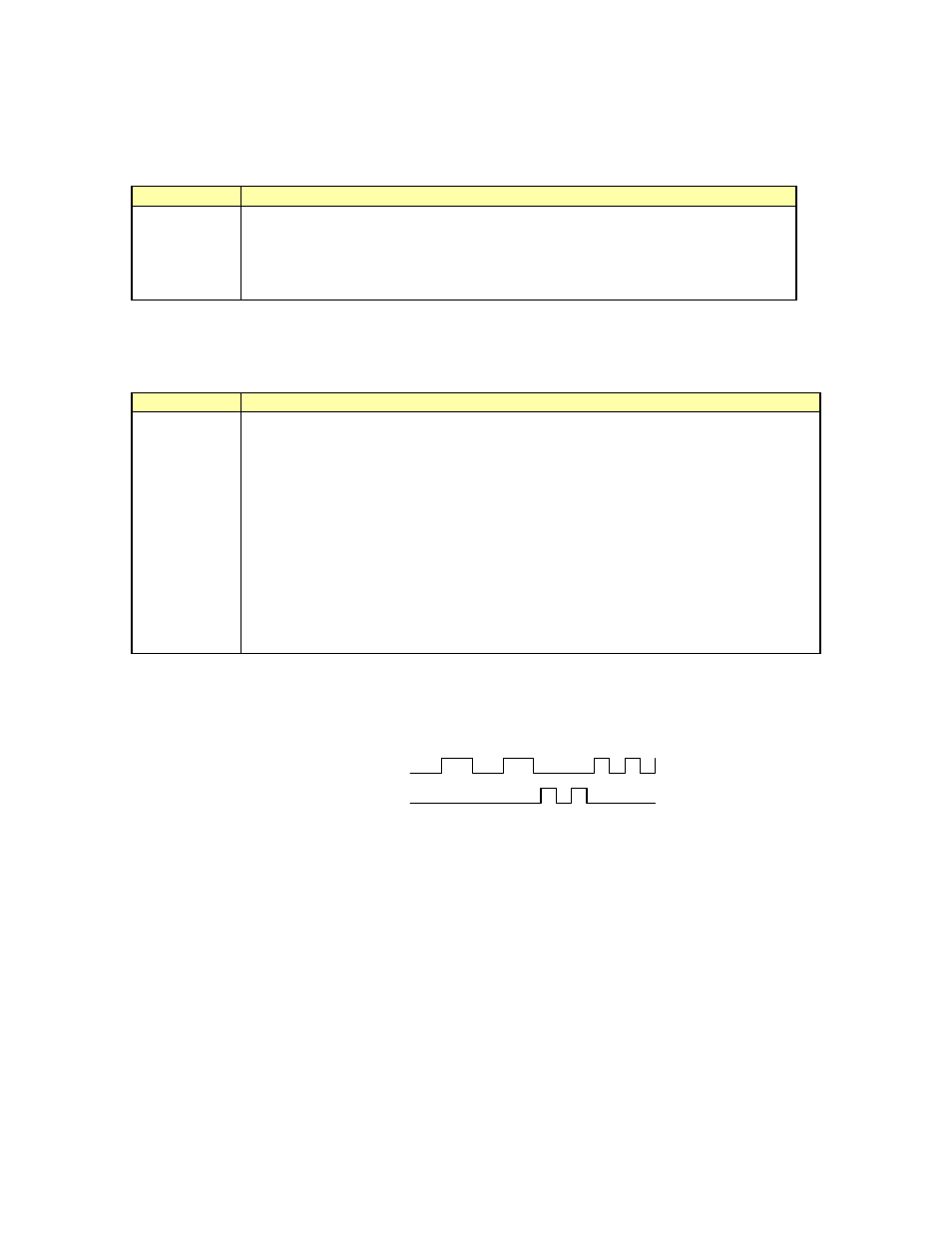

CWCNT (DI)

CWCNT (D0)

Figure 6. Rotary Motion Mode

Each rising edge of the CWCNT (D1) line will cause the position to be incremented by 1. Each rising edge

of the CCWCNT (D0) line will cause the position to be decremented by 1. Only a 32-bit counter will be

used, giving a count range from –(2^31) to (2^31)-1.

Unlike the previous modes, one data point will be saved for each sample. Sampling will be commanded by

the normal Command 3.

The following illustrates the counterclockwise (increasing negative values) and clockwise motions

(increasing positive values). The rotary motion detector will then be connected to DIG/SONIC2 and the

pulley spun counterclockwise.