Carrier 69NT40-511-199 User Manual

Page 95

SECT

IO

N

6

6-1

T-268-07

SECTION 6

SERVICE

NOTE

To avoid damage to the earth’s ozone layer, use a refrigerant recovery system whenever removing refrigerant.

When working with refrigerants you must comply with all local government environmental laws. In the

U.S.A., refer to EPA section 608.

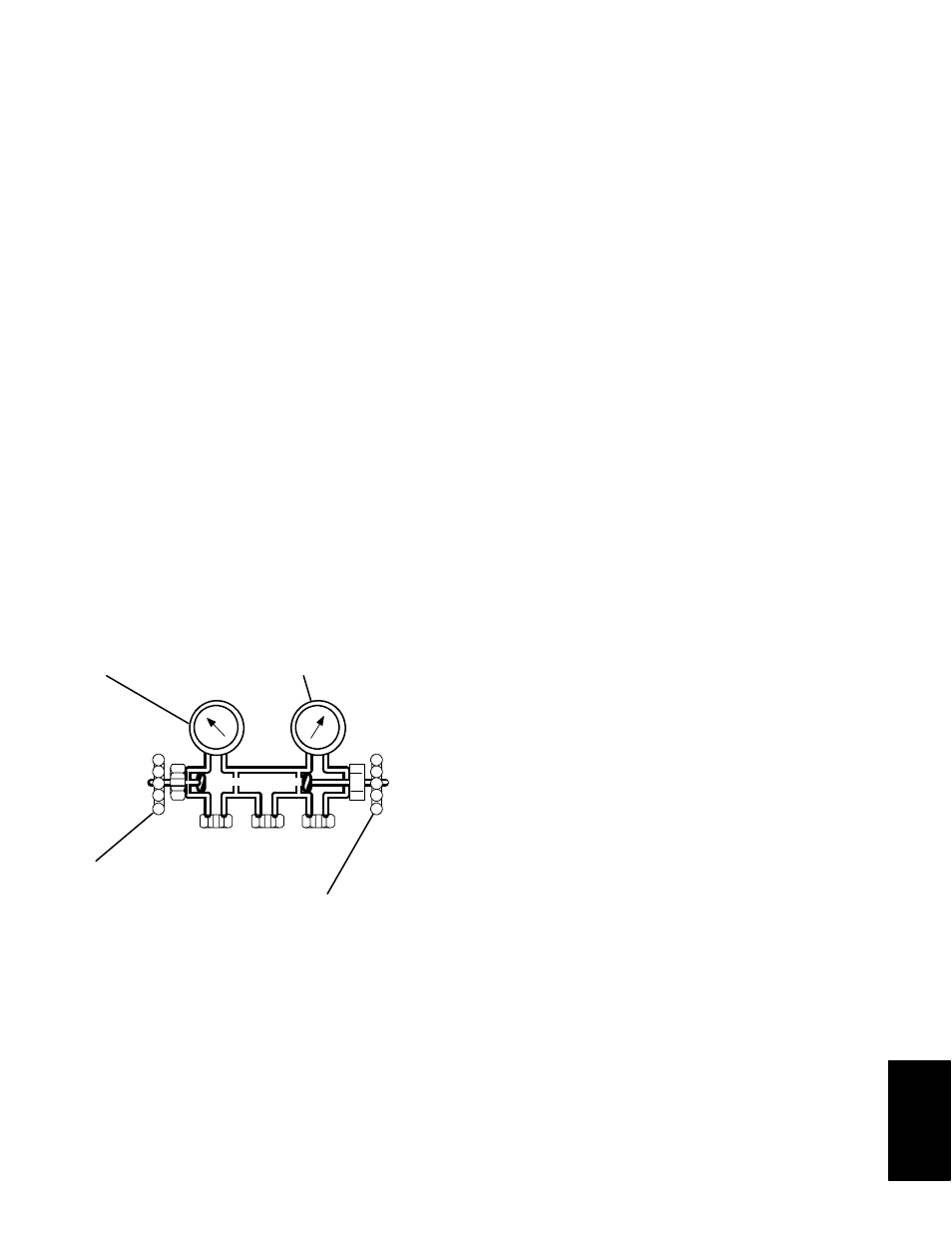

6.1 MANIFOLD GAUGE SET

The manifold gauge set can be used to determine system

operating pressure, add a refrigerant charge, and to

equalize or evacuate the system.

Figure 6-1 shows hand valves, gauges and refrigerant

openings. When the low pressure hand valve is

frontseated (turned all the way in), the low (evaporator)

pressure can be checked. When the high pressure hand

valve is frontseated, high (condensing) pressure can be

checked. When both valves are open (turned

counter-clockwise all the way out), high pressure vapor

will flow into the low side. When the low pressure valve

is open, the system can be charged. Oil can also be

added to the system.

Only a R-134a manifold gauge set with self-sealing

hoses, as shown in Figure 6-2 (CTD P/N 07-00294-00,

which includes items 1 through 6) can be used when

working on the models covered within this manual.

Opened

(Backseated Hand Valve )

Closed

(Frontseated Hand Valve)

Low Pressure Gauge

High Pressure Gauge

A

B

C

A. Connection to Low Side of System

B. Connection to High Side of System

C. Connection to Either:

Refrigerant Cylinder or

Oil Container

Figure 6-1. Manifold Gauge Set

a. Connecting the Manifold Gauge Set

(See Figure 6-2)

1. Remove service valve stem caps and check both

service valves to make sure they are backseated

(turned counter-clockwise all the way out). Remove

service port caps.

2. Connect the high side field service coupling

(backseated) to the discharge service valve port (or

the manual liquid line valve port, whichever is

applicable).

3. Turn the high side field service coupling (red knob)

clockwise, which will open the high side of the

system to the gauge set.

4. Connect the low side field service coupling to the

suction service valve port.

5. Turn the low side field service coupling (blue knob)

clockwise, which will open the low side of the

system to the gauge set.

6. To read system pressures: slightly midseat the

discharge and suction service valves, and frontseat

both manifold gauge set hand valves.

NOTE

If a manifold gauge set is new or was exposed to

the atmosphere due to repair, it will need to be

evacuated to remove contaminants and air as

follows:

S

Midseat both hand valves.

S

Connect the utility hose (yellow) to a vacuum

pump.

S

Evacuate to 10 inches of vacuum.

S

Charge with R-134a to a slightly positive

pressure of 0.1 kg/cm@ (1.0 psig). The gauge

set is now ready for use.