Carrier 69NT40-511-199 User Manual

Page 120

6-26

T-268-07

Ambient Temperature

Cold Coil

10_ F

6.45 ohms

40_ F

6.90 ohms

70_ F

7.40 ohms

100_ F

7.90 ohms

4. Plug in the connector for the modulation valve.

NOTE

A cold coil is a coil which has not been

operating and is assumed to be at ambient

temperature. Hot coils, taken after the unit has

been operating in deep modulation for a long

period of time, may give higher resistance

readings.

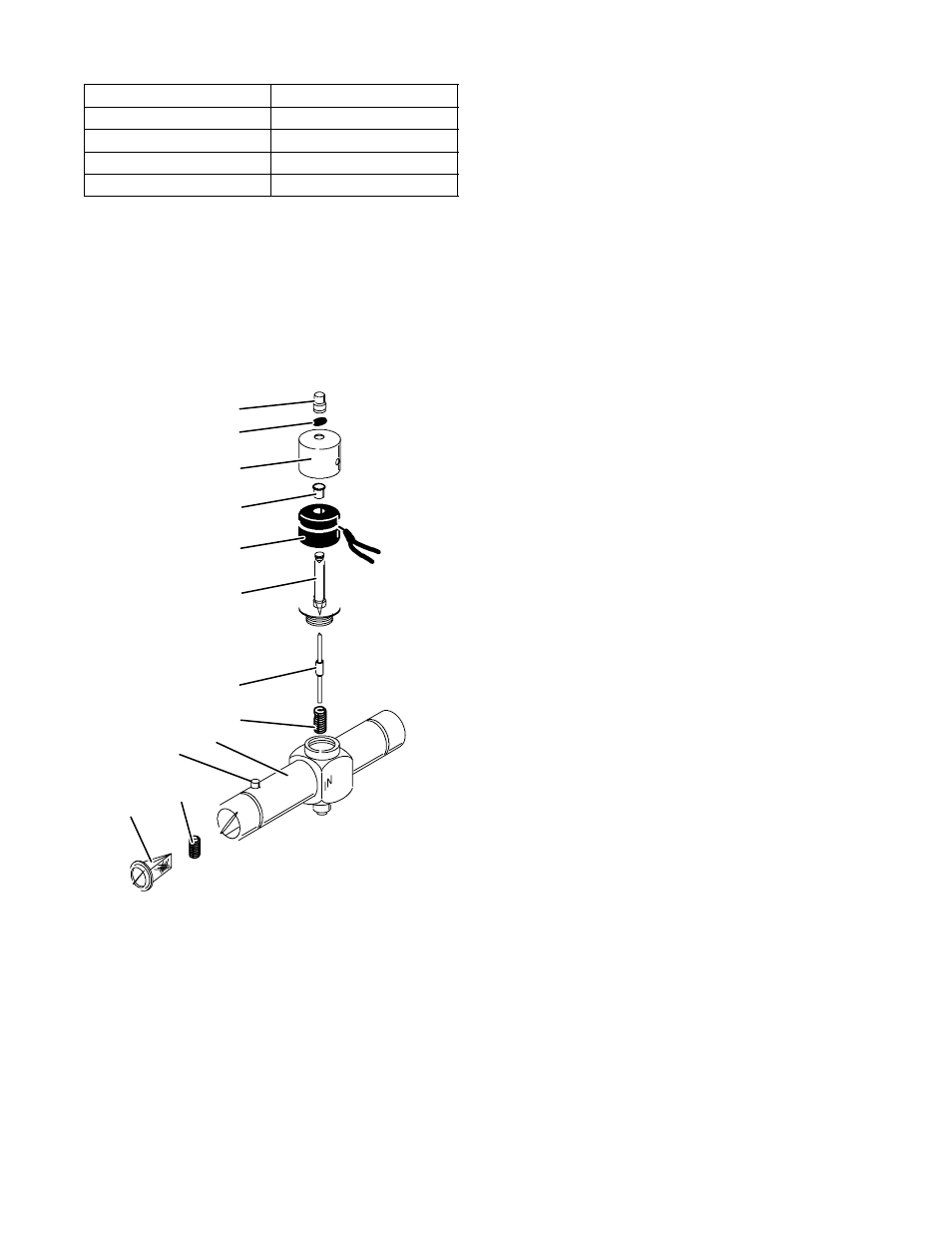

1

2

3

4

5

6

7

8

9

10

11

12

1. Coil Nut

2. Coil Nut O-ring

3. Coil Housing

4. Solenoid Coil Sleeve

5. Solenoid Coil

6. Enclosing Tube Assy.

7. Piston

8. Top Return Spring

9. Valve Body

10. Bottom Return Spring

11. Filter

12. Schrader Valve

Figure 6-28. Suction Modulation Valve (SMV)

b. Replacing the Coil

Remove locking nut and remove coil after

disconnecting wiring. When replacing nut, torque to a

value of 0.41 mkg (3 ft-lb).

c. To Replace Valve

1. Pump down the unit per section 6.3.

2. Remove two bolts from suction service valve.

3. Melt solder at modulating valve connection and

rotate valve and tubing enough to clear compressor.

Remove valve and tubing. Replace defective

suction modulation valve, being careful to wrap

body of replacement valve with a wet cloth while

brazing (inert gas brazing procedures MUST be

used only). The coil need not be removed.

4. Install new suction service valve gasket and install

bolts in suction service valve. Torque to a value of

2.77 to 4.15 mkg (20 to 30 ft/lb).

5. Solder all connections and leak check same.

6. Dehydrate and evacuate the unit per section 6.5.

Add refrigerant charge per section 6.6.

6.26 THERMOSTATIC EXPANSION VALVE

The thermal expansion valve is an automatic device

which maintains constant superheat of the refrigerant

gas leaving the evaporator, regardless of suction

pressure. The valve functions are:

(a) automatic

response of refrigerant flow to match the evaporator

load and (b) prevention of liquid refrigerant entering the

compressor. Unless the valve is defective, it seldom

requires any maintenance other than minor periodic

maintenance as follows:

1. Make sure that the excess capillary tube is secured

to the power head assembly and wrapped with

“Presstite.”

2. Make sure that the thermal bulb is tightly secured to

the suction line and wrapped with “Presstite.”

a. Removing Expansion Valve (See Figure 6-29)

1. Pump down the unit per section 6.3.

2. Remove insulation (Presstite) from expansion

valve bulb and power assembly and then remove

thermal bulb from the suction line.

3. Loosen flare nut and disconnect equalizing line

from expansion valve.

4. Remove capscrews and lift off power assembly and

remove cage assembly. Check for foreign material

in valve body.