Carrier 69NT40-511-199 User Manual

Page 109

SECT

IO

N

6

6-15

T-268-07

suction service valve flange cavity or by removing the

oil fill plug. (See Figure 6-5.) Some compressors have

the oil plug located on the crankcase, at the right or left

side of the oil pump.

d. To Remove Oil From an 06DR Compressor:

1. If the oil level recorded in step a.3 is above

one-eighth level of the capacity of the sight glass,

oil must be removed from the compressor.

2. Close (frontseat) suction service valve and pump

unit down to 1.2 to 1.3 kg/cm@ (2 to 4 psig).

Frontseat discharge service valve and slowly bleed

remaining refrigerant.

3. Remove the oil drain plug on the bottom plate of the

compressor and drain the proper amount of oil from

the compressor to obtain the correct level

(maximum is one-eight level of the sight glass).

Replace the plug securely back into the compressor.

DO NOT FORGET TO OPEN SUCTION AND

DISCHARGE SERVICE VALVES.

4. Repeat step (a) to ensure proper oil level.

6.11 FILTER-DRIER

On units equipped with a water-cooled condenser, if the

sight glass appears to be flashing or bubbles are

constantly moving through the sight glass when the

suction modulation valve is fully open, the unit may

have a low refrigerant charge or the filter-drier could be

partially plugged.

To Check Filter-Drier:

a. Test for a restricted or plugged filter-drier by feeling

the liquid line inlet and outlet connections of the

drier cartridge. If the outlet side feels cooler than the

inlet side, then the filter-drier should be changed.

b. A second test for moisture in the filter-drier is that

the moisture-liquid indicator shows moisture in the

system.

To Replace Filter-Drier:

a. Pump unit down to 0 psi and replace filter-drier.

(Refer to section 6.3.)

b. Evacuate the unit per section 6.5 and open the

manual liquid line valve.

c. After unit is in operation, inspect for moisture in

system.

6.12 HIGH PRESSURE SWITCH

6.12.1 Replacing High Pressure Switch

a. Turn unit start-stop switch OFF. Frontseat both

suction and discharge service valves to isolate

compressor. Remove the refrigerant from the

compressor.

b. Disconnect wiring from defective switch. The high

pressure switch is located on the center head and is

removed by turning counterclockwise. (See

Figure 2-1.)

c. Install a new high pressure switch after verifying

switch settings. (Refer to section 6.12.2.)

d. Evacuate and dehydrate the compressor per

section 6.5.1.

6.12.2 Checking High Pressure Switch

WARNING

Do not use a nitrogen cylinder without a

pressure regulator. Do not use oxygen in or

near a refrigeration system as an explosion

may occur.

NOTE

The

high

pressure

switch

(HPS)

is

non-adjustable.

a. Remove switch as outlined in section 6.12.1.

b. Connect ohmmeter or continuity light across switch

terminals. Ohm meter will indicate no resistance or

continuity light will be illuminated if the switch

closed after relieving compressor pressure.

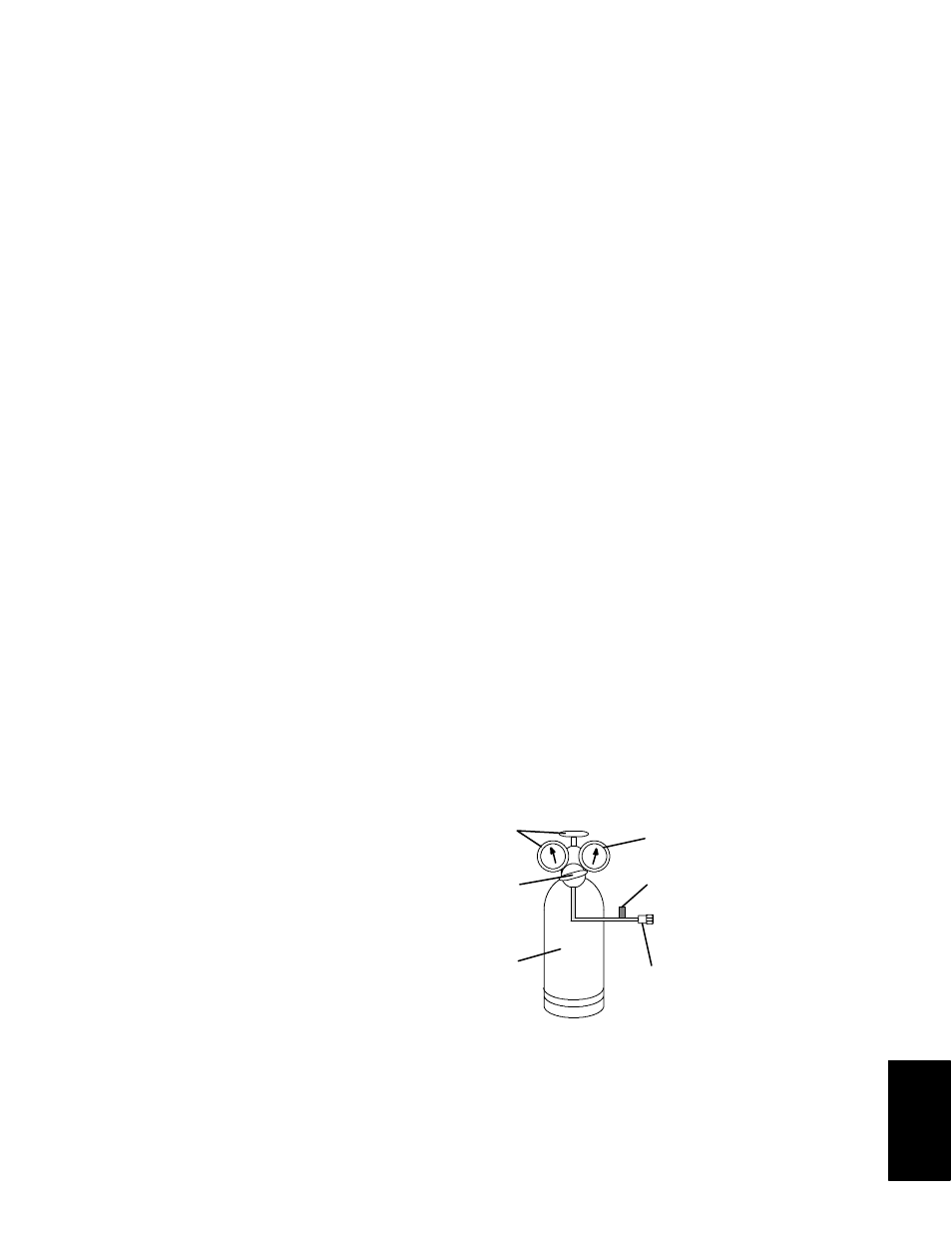

c. Connect hose to a cylinder of dry nitrogen. (See

Figure 6-17.)

1. Cylinder Valve

and Gauge

2. Pressure Regulator

3. Nitrogen Cylinder

4. Pressure Gauge

(0 to 36 kg/cm@ =

0 to 400 psig)

5. Bleed-Off Valve

6. 1/4 inch Connection

1

2

3

4

5

6

Figure 6-17. Typical Setup for Testing

High Pressure Switch

d. Set nitrogen pressure regulator at 26.4 kg/cm@ (375

psig) with bleed-off valve closed.

e. Close valve on cylinder and open bleed-off valve.