Carrier 69NT40-511-199 User Manual

Page 107

SECT

IO

N

6

6-13

T-268-07

6.9 COMPRESSOR REASSEMBLY

To clean compressor parts, use a suitable solvent with

proper precautions. Coat all moving parts with the

proper compressor oil before assembly. Refer to

Table 6-5 for applicable compressor torque values.

1

2

3

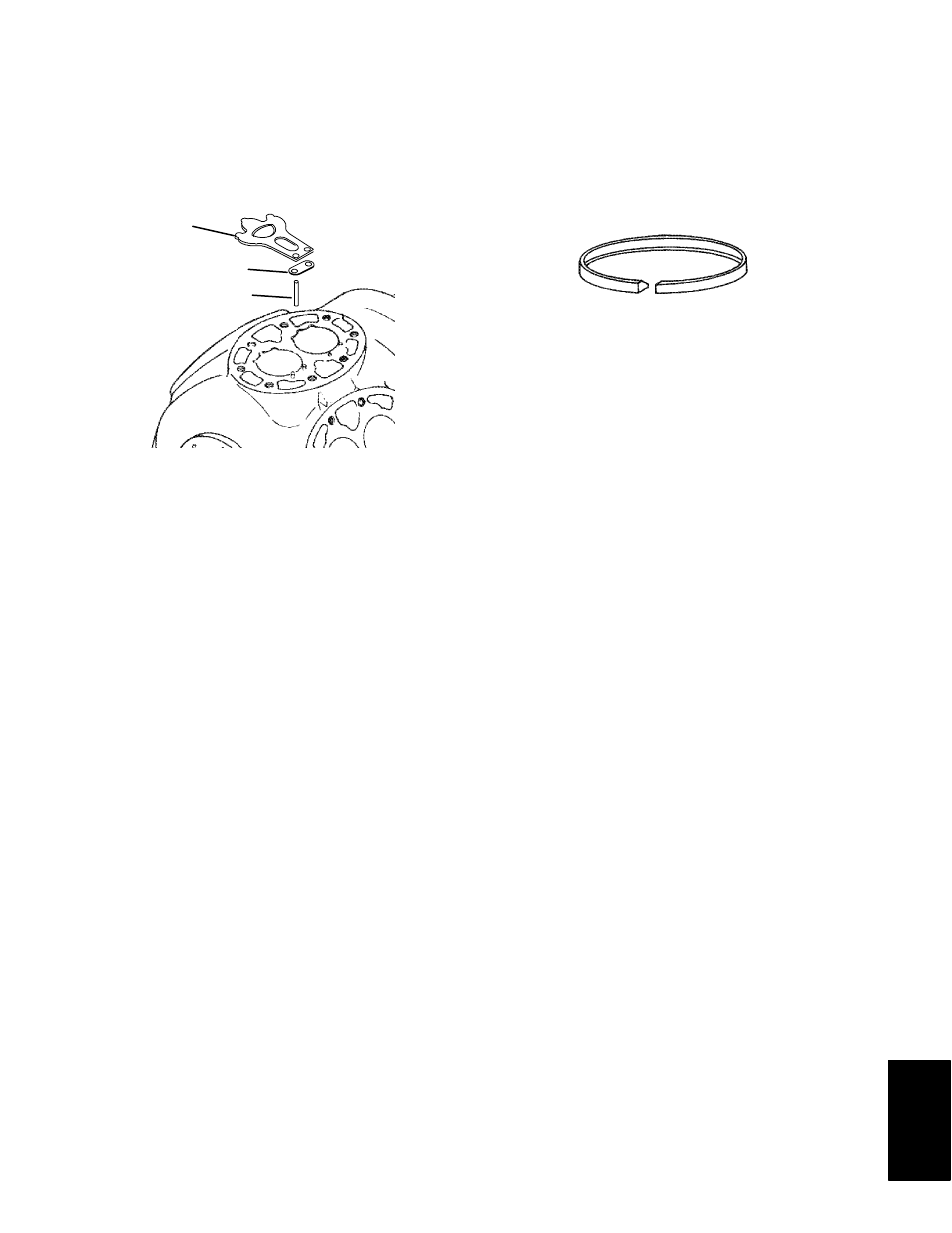

1. Suction Valve

2. Suction Valve Positioning Spring

3. Valve Plate Dowel Pin

Figure 6-14. Suction Valve & Positioning Springs

a. Suction and Discharge Valves

If the valve seats look damaged or worn, replace valve

plate assembly. Always use new valves because it is

difficult to reinstall used discharge valves so that they

will seat as before removal. Any valve wear will cause

leakage for this reason.

Suction valves are positioned by dowel pins (see

Figure 6-14) and will assume their original position

when reinstalled. No two valves are likely to wear in

exactly the same way. Never interchange used valves.

Do not omit the suction valve positioning springs. (See

Figure 6-14.) Place the springs so that the ends bear

against the cylinder deck (middle bowed away from

cylinder deck). Use new gaskets when reinstalling valve

plates and cylinder heads.

b. Compression Rings

The compression ring is chamfered on the inside

circumference. This ring is installed with the chamfer

toward the top. Stagger the ring end gaps so they are not

aligned.

The gap between the ends of the piston rings can be

checked with a feeler gauge by inserting the ring into the

piston bore approximately one inch below the top of the

bore. Square the ring in the bore by pushing it slightly

with a piston. The maximum and minimum allowable

ring gaps are 0.33 and 0.127 mm (0.013 and 0.005 inch)

respectively.

Figure 6-15. Piston Rings

c. Installing the Components

1. Push pistons from the inside of the crankcase

through the cylinders, being careful not to break the

rings. Place chamfered side of connecting rod

against radius of crankpins. Install the crankshaft

through the pump end of the compressor. Do not

damage main bearings. Install matching connecting

rod caps through bottom cover plate.

2. The oil screen (located in the bottom of the

crankcase), is connected to the inlet of the oil pump.

Whenever the compressor crankcase is opened,

inspect the screen for holes or an accumulation of

dirt. The screen can be cleaned with a suitable

solvent.

CAUTION

The set screw on the crankshaft must be

removed for the oil pump installation (see

Figure 6-8).

3. Install the pump end thrust washer on the two dowel

pins located on the bearing head. (See Figure 6-8)

CAUTION

Ensure that thrust washer does not fall off

dowel pins while installing oil pump.

4. Install the bearing head assembly with a new gasket

on the compressor crankshaft. Carefully push oil

pump on by hand, ensuring that the thrust washer

remains on the dowel pins. The tang on the end of

the drive engages the slot in the crankshaft, and the

oil inlet port on the pump is aligned with the oil

pickup tube in the crankcase. The pump should

mount flush with the crankcase and should be

oriented as shown in Figure 6-16.