English pg4 – Park Tool PK-65 User Manual

Page 4

English pg4

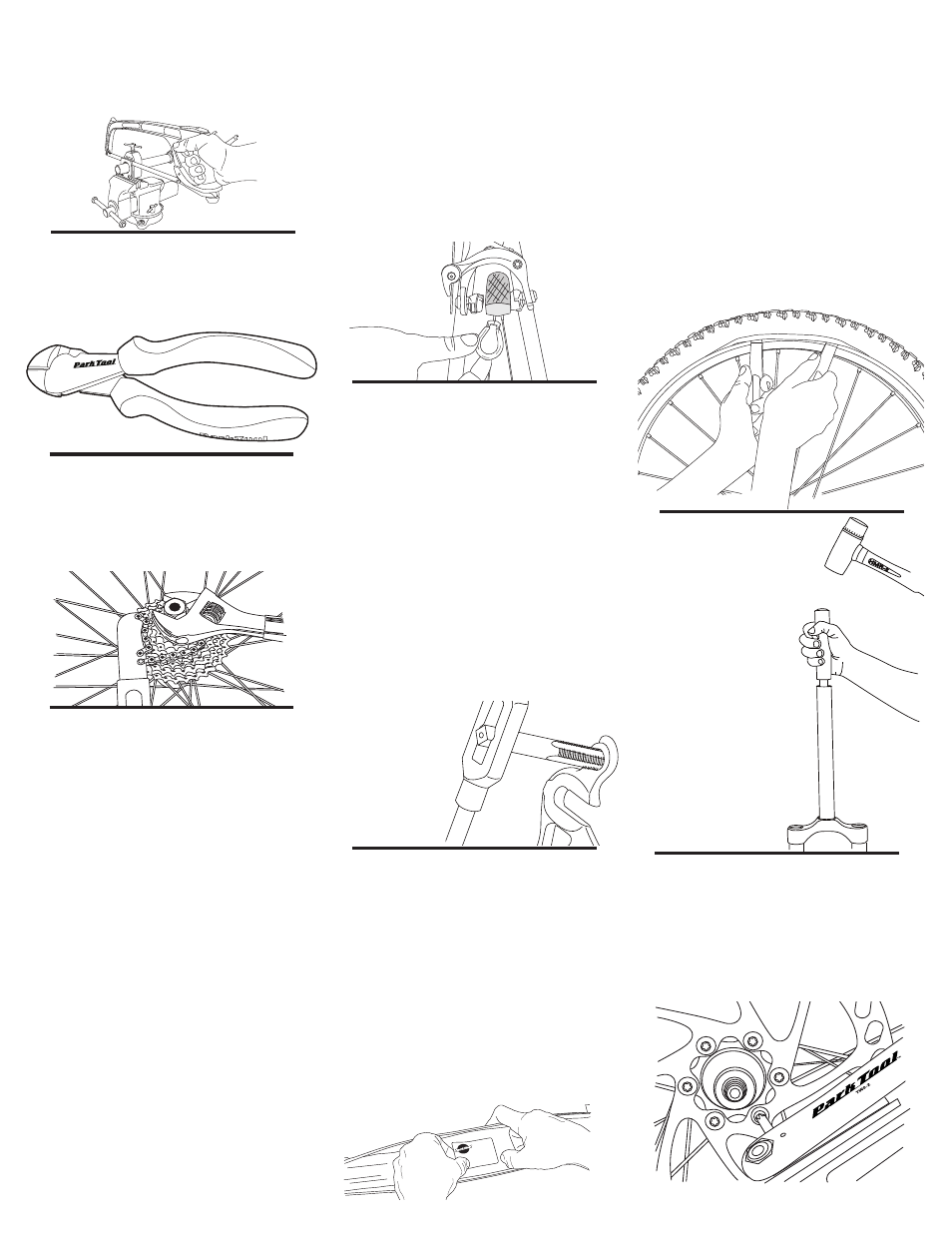

SR-11 Chain Whip

The SR-11 is used when removing cassette cogs

from the rear wheel. It firmly holds the cassette

cogs so a cassette lockring tool can be used to

remove the cassette lockring.

TB-2

Emergency T

ire Boot

TB-2 Emergency Tire Boot

The TB-2 Tire Boot quickly and easily installs to

patch cuts, scrapes, and tears in any size tire.

The thin, reinforced tire boot film adheres to

the inside of the tire and prevents the tube from

protruding out of the cut or tear.

Instructions:

Locate cut or tear then clean and dry surrounding

surface to promote adhesion of boot. Peel

the protective backing from TB-2 and apply,

allowing TB-2 to adequately overlap damaged

area. Note: The TB-2 is designed for emergency

use. A patched tire should be replaced as soon

as possible.

TL-6 Tire Levers

Tire levers are designed to remove tires from the

rim of a wheel. TL-6 Tire Levers are covered with

a special composite material, which prevents

scratching when removing tires from carbon

fiber, anodized and painted rims.

TNS-1 Threadless

Nut Setter

The TNS-1 is used to

install the star-fangled

nut found on 1” and

1-1/8” threadless headset

systems. Thread the nut

onto the TNS-1, insert

into the fork stack, and

tap it in with a hammer.

Sets the star-fangled

nut to 15mm and keeps

it straight.

TWS-2 Torx

®

Compatible

Star-Shaped Driver Set

The TWS-2 includes the star-shaped wrench

sizes currently being used on components such

as disc brakes, pedals and chain rings (T7, T9,

T10, T15, T20, T25, T27, T30 and T40).

Instructions:

Deflate tire completely. Push bead of tire from

edge of rim. Insert tip of one lever under bead.

Insert tip of second lever under bead 8 - 10 cm

from first lever. Push down on both levers to pry

up bead. Slide second lever along rim until bead

is completely removed. Remove second tire bead

from rim to completely remove tire and tube.

the area of the wobble ¼ turn. Spin the

wheel slowly and note the impact. Repeat

as needed to remove the wobble. Note: If

further tightening could cause damage to

the nipple or create uneven spoke tension,

similar results can be obtained by loosening

the opposite side nipples ¼ turn within the

area of the wobble. For example, if the rim

wobbles to the right, loosen the right side

nipples within the area of the wobble.

4. Repeat procedure on other wobbles until the

wheel runs straight through the brake pads.

SW-0, SW-1, and SW-2

Professional Spoke Wrenches

A wheel occasionally needs to be straightened

or “trued” in order to keep the rim running

straight as it passes between the brake pads.

A spoke wrench is required for tightening and

loosening spoke nipples when truing a wheel.

SW-0 (Black): .127 (3.23mm)

SW-1 (Green): .130 (3.30mm)

SW-2 (Red): .136 (3.45mm)

Instructions:

Detailed instructions for truing wheels can be

found in a number of books, as well as on-line

at www.parktool.com. Below are instructions

for basic lateral truing, which can easily be

performed with the wheel in the bike.

1. Place bike in Park Tool Repair Stand or lift

bike off the ground so wheel can spin freely.

2. Spin wheel slowly and look for side-to-side

wobbles as the rim travels between the

brake pads.

3. If the rim wobbles to the right, tighten the

left side nipples within the area of the

wobble ¼ turn. If the rim wobbles to the

left, tighten the right side nipples within

SG-6 Threadless Saw Guide

The SG-6 ensures a straight, clean cut on

1”, 1-1/8”, and 1-1/4” threadless forks. See

information sheet packaged with tool for

complete instructions.

SP-7 Side Cutter Pliers

The SP-7 is a professional quality cutter for

cutting brake housing, accessory zip ties, etc.

TAP-10 10mm x 1 Frame Tap

The TAP-10 is used to restore damaged threads

in a bike frame’s derailleur hanger.

Instructions:

1. Insert TAP-10 into tap handle (Park Tool TH-1

or similar).

2. Apply cutting fluid to threads.

3. Turn tap handle clockwise, keeping tap going

straight into threads as it turns. Threads

will be further damaged if tap is not going

straight.

4. After each clockwise turn, turn tap counter-

clockwise 1/2 turn to break and clear metal

chips or other material formed during the

tapping process.

5. Turn tap counter-clockwise to remove. Clean

chips and cutting fluid from threads.

Note: Frame taps

are fragile and can

shatter. Always use

eye protection.

SP-7

© 2014 Park Tool Co.

PARK TOOL® and the color BLUE are registered trademarks of Park Tool Co.

All other referenced trademarks and trademark registrations are the property of their respective owners.