Park Tool Derailleur Hanger Alignment Gauge User Manual

Dag-2 derailleur hanger alignment gauge, Assembly, Instructions

Park Tool Co.

5115 Hadley Ave. N., St. Paul, MN 55128 (USA) www.parktool.com

DAG-2 Derailleur Hanger

Alignment Gauge

Proper alignment of a bike’s derailleur hanger is important for reliable shifting. While a derailleur hanger can be

bent when a bike is crashed or dropped on its side, even new frames often have misaligned hangers. The Park Tool

DAG-2 provides a simple, accurate means for checking hanger alignment and for straightening hangers that are not

properly aligned

ASSEMBLY

Install indicator (Ref #4) into sliding bracket

(Ref #7) and tighten knob (Ref #1). Install one

o-ring at each end of indicator. The o-rings

will serve to retain indicator in the DAG-2.

INSTRUCTIONS

1. Install wheel in frame. Make sure rim

is correctly centered in frame.

2. Remove derailleur from derailleur

hanger.

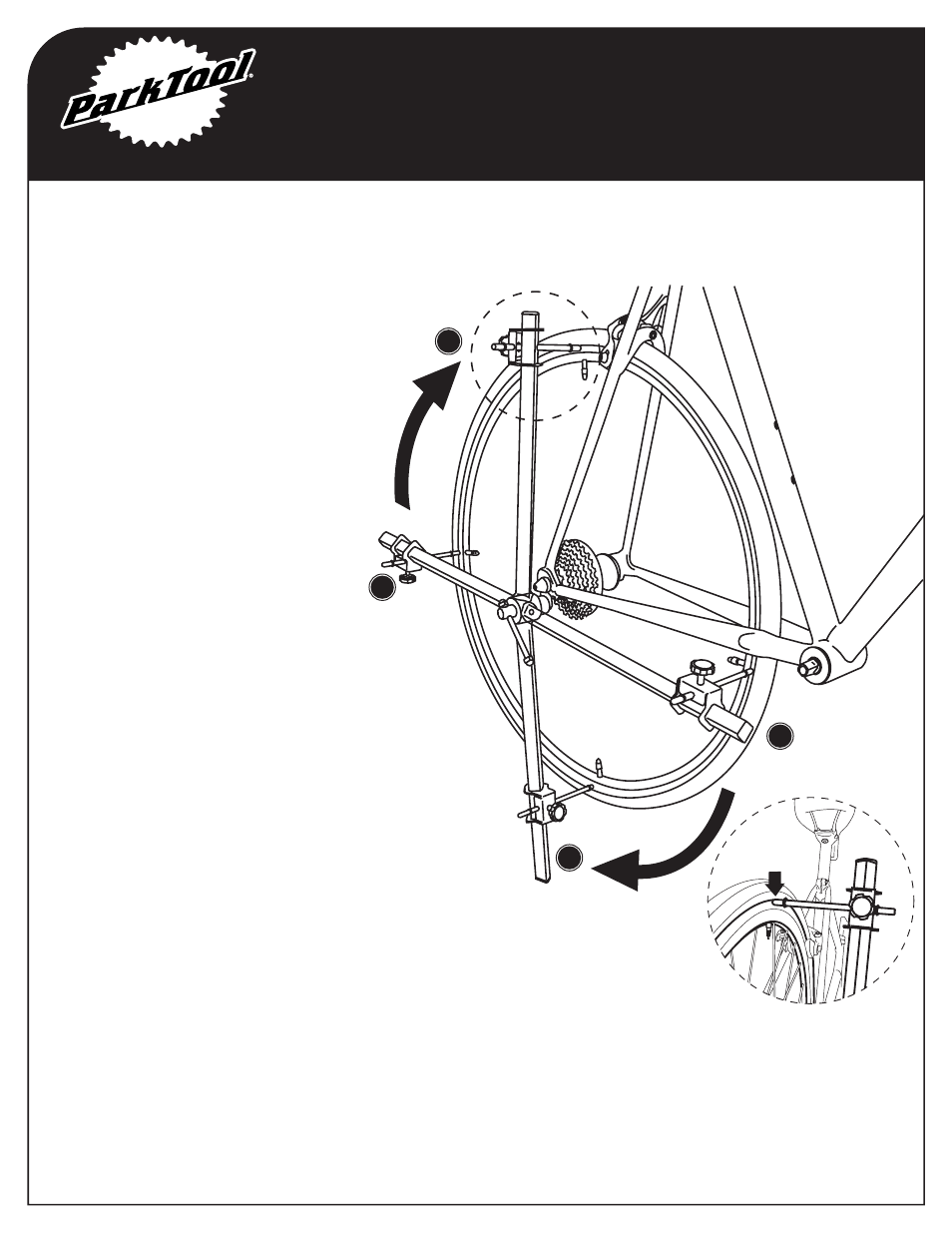

3. Thread inside shaft (Ref #3) into derail-

leur mounting hole.

4. Loosen knob and move sliding bracket

and indicator so tip of indicator contacts outside

edge of rim (position A). Tighten knob.

5. Move sliding bracket so indicator is clear of rim.

Then rotate tool 180 degrees to position C.

6. Move sliding bracket and indicator to outside edge

of rim. If tip of indicator is within 4mm of outside

edge of rim, the hanger is aligned horizontally. If tip

of indicator is 4mm or more away from rim, or if indica-

tor presses against rim, the hanger is misaligned. Move

sliding bracket and indicator so they are clear of rim. Then

use weldment (Ref #6) as a lever to bend hanger into

alignment horizontally. Repeat checking and bending be-

tween positions A and C until clearance is less than 4mm.

7. After achieving correct horizontal alignment, keep indica-

tor in same position and rotate to position B. If clearance

between outer edge of rim and tip of indicator is less than

4mm, rotate tool to position D. If clearance is greater than 4mm,

or if indicator presses against rim at position B or D, use weld-

ment as a lever to align hanger vertically.

8. With properly aligned hanger, tip of indicator should just contact

outer edge of rim at one position and have no more than 4mm

clearance at any of the other positions. Check and align all four

positions until this is accomplished.

Notes

The two o-rings on the gauge bar may be used as markers when using the DAG-2 on a bike with interference from

a rack or other accessory. After moving indicator to rim and tightening knob, move outer o-ring against sliding

bracket. When it’s necessary to clear a rack or other accessory, simply loosen knob, pull indicator back to clear rack

or other accessory, push indicator in until o-ring contacts sliding bracket in original position, and tighten knob.

Always take

readings with

indicator at

valve hole to

insure wheel

trueness will not impact accuracy of tool.

Also, always take readings at outside edge of

rim to minimize errors that may be caused by

rim’s sidewall slope.

C

B

A

D