Park Tool TW-2 User Manual

Tw-1 & tw-2 torque wrench, Torque conversion formulas

Park Tool Co.

www.parktool.com

TW-1 & TW-2 Torque Wrench

© 2012 Park Tool Co. / ® PARK TOOL and the color BLUE are registered trademarks of Park Tool Co.

TORQUE WRENCH

TW-1 (0 – 60 Inch Pounds/ 0 – 7 Newton Meters)

TW-2 (0 – 600 Inch Pounds/ 0 – 70 Newton Meters)

To prevent over tightening and under tightening of bolts and nuts, specific torque specifications are

provided by most bicycle component manufactures. TW-1 and TW-2 Torque Wrenches accurately

measure the amount of torque (turning or twisting force) being applied to a bolt or nut.

CALIBRATION

The pointer tip of the TW-1 and TW-2 should line up with the “0” on the scale plate. It should also

“float” over the scale plate, without contact. If this is not the case, simply bend the pointer near the

head of the wrench until the pointer tip is in the correct position. Bending the pointer will not damage

the wrench or impact its accuracy.

TORQUE WRENCH USE

1.

Install desired wrench bit (not included) onto square head of torque wrench. The TW-1 accepts

1

⁄

4

” drive bits and

3

⁄

8

” drive bits (with the included adapter). The TW-2 accepts

3

⁄

8

” drive bits.

2.

Place bit and wrench onto bolt or nut to be tightened.

3.

Grasp handle of torque wrench. NOTE: The TW-2 uses a pivoting handle for greater

accuracy. When using the TW-2, grasp handle so that force is balanced at the pivot point

(Figure 1). Accuracy is affected if other parts of the handle contact the beam while in use.

4.

Turn wrench on bolt or nut with steady pressure until tip of pointer reaches the desired torque

on the scale plate. The bolt or nut should be in motion when the final torque reading is made

on the scale plate.

IMPORTANT INFORMATION

1

.

Clean threads and remove burrs from bolts and nuts before assembly. Lubricate threads with

appropriate grease, oil or anti-seize lubricant for proper tightening and accurate torque reading.

Do not lubricate bolts or nuts using a nylon or “Nylok” thread fitting.

2

.

If flexible adapters or crow-foot extensions are used, re-calculate

the needed torque using the formula:

Torque (T) = Force (F) x Distance (D).

3

.

Torque wrenches are precision tools. Store carefully to

avoid damage. Any defacement of the beam will impact

the accuracy of the wrench and result in failure.

For additional information on torque concepts, specifications,

conversion tables, and torque wrench use:

www.parktool.com

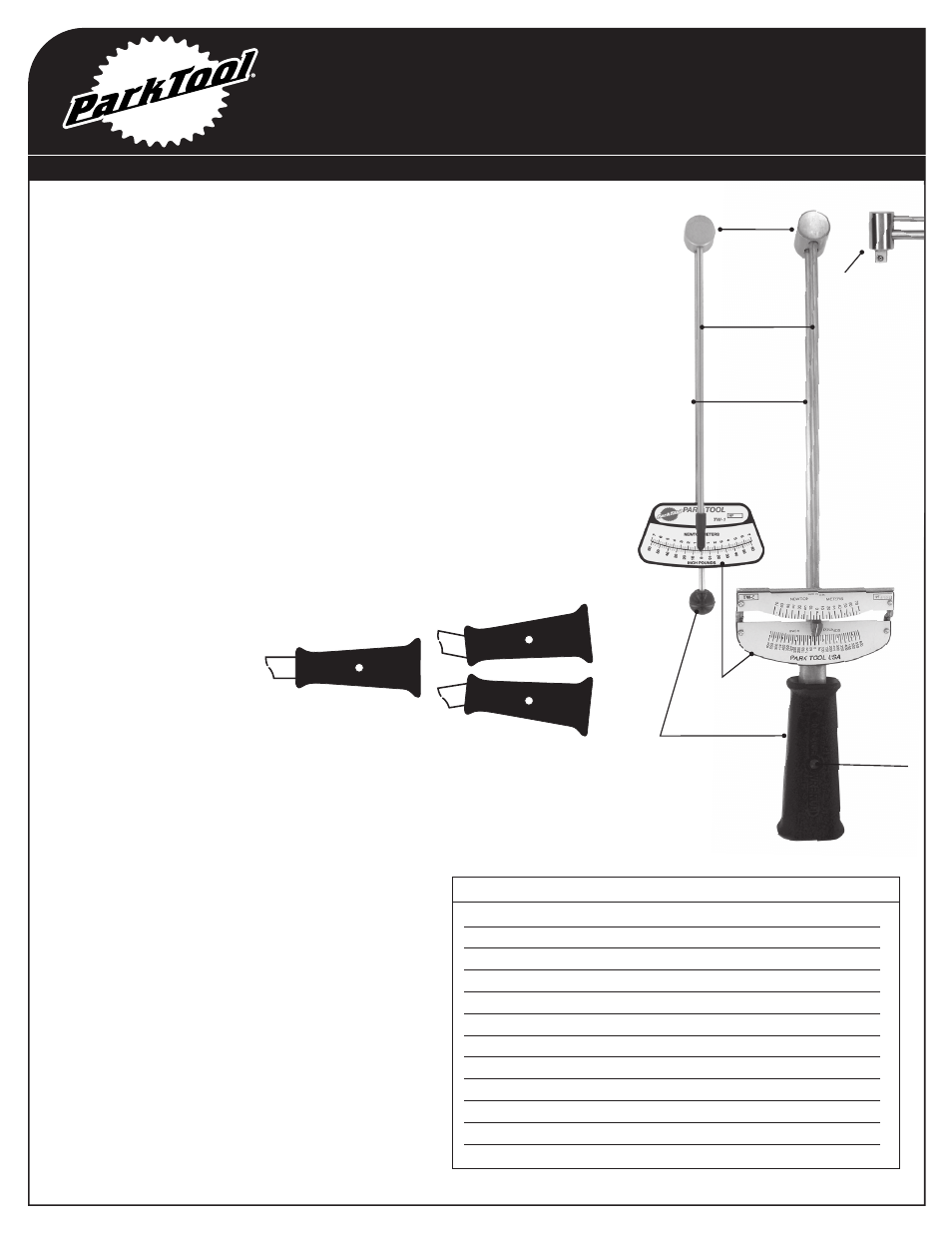

Right

Richtig

Bon

Posición correcta

Wrong

Falsch

Mauvais

Posición incorrecta

(Figure 1) - TW-2 handle only

(Bild 1) - Nur TW-2 handgriff

(Figure 1) - Poignée du TW-2 uniquement

(Figura 1) - Solo maneral del TW-2

Head

Kopf

Tête

Cabeza

Square Drive

Vierkantaufnahme

Embout carré

Acoplador para Dado

Pointer

Zeiger

Pointeur

Indicador

Beam

Hebelarm

Bras de levier

Barra

Scale Plate

Skalenblatt

Plaque graduée

Escala

Handle

Handgriff

Poignée

Maneral

Pivot point

Drehgelenk

Point de pivot

Punto del Pivote

To Convert

To

Multiply by

Inch Pounds

Foot Pounds

0.08333

Inch Pounds

Newton Meters

0.113

Inch Pounds

Centimeter Kilograms

1.1519

Foot Pounds

Inch Pounds

12

Foot Pounds

Newton Meters

1.356

Foot Pounds

Centimeter Kilograms

13.825

Newton Meters

Inch Pounds

8.85

Newton Meters

Foot Pounds

0.7376

Newton Meters

Centimeter Kilograms

10.2

Centimeter Kilograms

Inch Pounds

0.8681

Centimeter Kilograms

Foot Pounds

0.07233

Centimeter Kilograms

Newton Meters

0.09807

TORQUE CONVERSION FORMULAS