Installation guidelines – Waterworks 25 Thermostatic Valve User Manual

Page 2

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

.25

THERMOSTATIC VALVE

INSTALLATION GUIDELINES

Page 2 of 2

6.18.2014

These guidelines have been prepared for the professional contractor to aid in the installation of:

.25 THERMOSTATIC VALVE STYLE NO. GUTH78, GU78TH (UK)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

FLUSH OUT THE SYSTEM:

¾ Before installing the cartridge, the supply lines must

be flushed out to prevent clogging of the filter

screens. Failure to flush the lines will permanently

damage the cartridge and void the warranty. Repeat

this process as needed prior to trim installation.

¾ See Figure - 04 for steps 7-11.

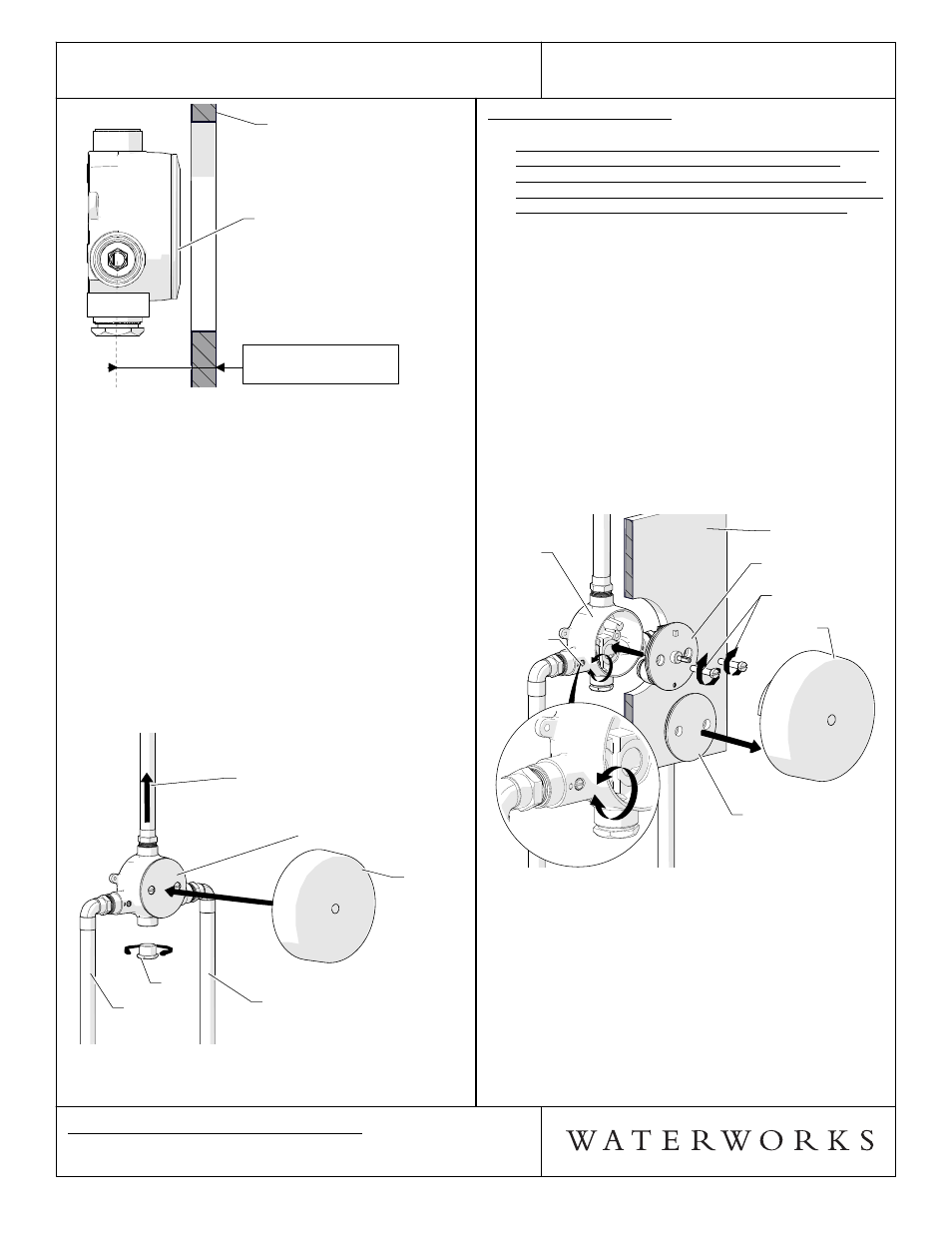

7. The VALVE BODY is shipped with the FLUSH PLATE

pre-installed, and is ready for flushing the lines.

8. Turn on the water supply and open the SERVICE

STOPS to flush out the lines then inspect all

connections for leaks.

9. After the lines are flushed, turn off the water supply

and close the SERVICE STOPS, unthread the 2 cover

SCREWS, then remove the FLUSH PLATE.

10. Install the CARTRIDGE using the 2 cover SCREWS

and turn off the SERVICE STOPS.

11. Re-attach the TILE GUARD to protect CARTRIDGE .

TILE

GUARD

FINISHED

WALL

VALVE

BODY

SERVICE

STOP

CARTRIDGE

FLUSH PLATE

SCREWS

TILE

GUARD

FINISHED

WALL

VALVE

BODY

SERVICE

STOP

CARTRIDGE

FLUSH PLATE

SCREWS

FIGURE - 04

¾ If further assistance is required, please contact

Product Support at 1-800-927-2120 (8am-6pm EST).

¾ See service part document for parts ordering,

available on WATERWORKS.COM.

† BSP Adapter can be ordered separately:

(4x)

STYLE No. UNUK01

ITEM No. 45-22566-33137

FINISHED

WALL

.25 THERMOSTATIC VALVE

(FLUSH PLATE PRE-INSTALLED)

FINISHED

WALL

.25 THERMOSTATIC VALVE

(FLUSH PLATE PRE-INSTALLED)

ROUGH-IN DEPTH

3-1/8" MIN - 4" MAX

(79mm MIN - 102mm MAX)

CENTER OF

INLETS

FIGURE - 02

¾ See Figure - 03 for steps 3-6.

3. Run 3/4" (22mm) copper supply lines to the proper

height of the valve inlets and be sure to secure all

piping and fittings.

4. For each fitting that will have water flowing to it,

install a wall valve or diverter valve (both sold

separately) at the same rough in depth and

according to the flow direction arrow marked on the

wall valve or diverter valve body.

5. The bottom port of the valve body has a PLUG pre-

installed, but can be removed and the bottom port

can be used to supply water to other fittings.

6. Install the TILE GUARD to protect the valve during

the completion of the finished wall and to create the

exact opening for access to the service stops and

future servicing.

3/4" (22mm)

COLD SUPPLY

PLUG

.25 THERMOSTATIC VALVE

(FLUSH PLATE PRE-INSTALLED)

OUTLET

TO VOLUME

CONTROL VALVE

(SOLD SEPARATELY)

3/4" (22mm)

HOT SUPPLY

TILE

GUARD

3/4" (22mm)

COLD SUPPLY

PLUG

.25 THERMOSTATIC VALVE

(FLUSH PLATE PRE-INSTALLED)

OUTLET

TO VOLUME

CONTROL VALVE

(SOLD SEPARATELY)

3/4" (22mm)

HOT SUPPLY

TILE

GUARD

FIGURE - 03