Installation guidelines – Waterworks Ludlow Three Way Diverter Trim for Thermostatic System with Lever Handle User Manual

Page 2

PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

LUDLOW

Diverter Trim Plates

INSTALLATION GUIDELINES

Page 2 of 2

2.11.2014

These guidelines have been prepared for the professional contractor to aid in the installation of:

LUDLOW DIVERTER TRIM PLATES (STYLE# SEE ABOVE) All dimensions are based on original

specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

SEE SERVICE PART DOCUMENT FOR PART ORDERING, AVAILABLE ON WATERWORKS.COM

IMPORTANT:

¾ To ensure this product is installed properly, you

must read and follow these guidelines.

¾ The owner/user of this product must keep this

information for future reference.

¾ This product must be installed with a Two or Three

Way Diverter Valve (SOLD SEPARATELY). Please

refer to the specific valve installation guidelines for

rough-in requirements.

¾

Be sure your installation conforms to federal state,

and local codes. In the State of Massachusetts, all

installations must comply with the rules and

regulations set forth within 248 CMR.

¾ This product must be installed by a professional

licensed contractor and must be onsite prior to

rough-in, this allows the installer to visualize the

installation.

¾ Inspect this product to ensure you have all the parts

required for proper installation.

¾ Use only a strap wrench or protected/smooth-jaw

wrench on any finished surface.

¾ The use of certain plumber's putty may stain stone

or tile surfaces.

DIVERTER VALVE INSTALLATION:

¾ See Figure 1 for steps 1 - 3

1.

Pull the tile guard off the THREADED TUBE on the

diverter valve rough. Mark the THREADED TUBE at

the finished wall. Unthread the TUBE and cut 1/8"

behind the mark.

2. Cut the CARTRIDGE STEM 1-1/4" in front of the

finished wall.

3. After the cuts have been made, thread the

THREADED TUBE back onto valve body.

Figure 1

ROUGH-IN DEPTH

REFER TO PAGE 1

FINISHED WALL

CUT THREADED

TUBE

1

8

" BEHIND

FINISHED WALL

CUT

CARTRIDGE STEM

1-

1

4

" IN FRONT OF

FINISHED WALL

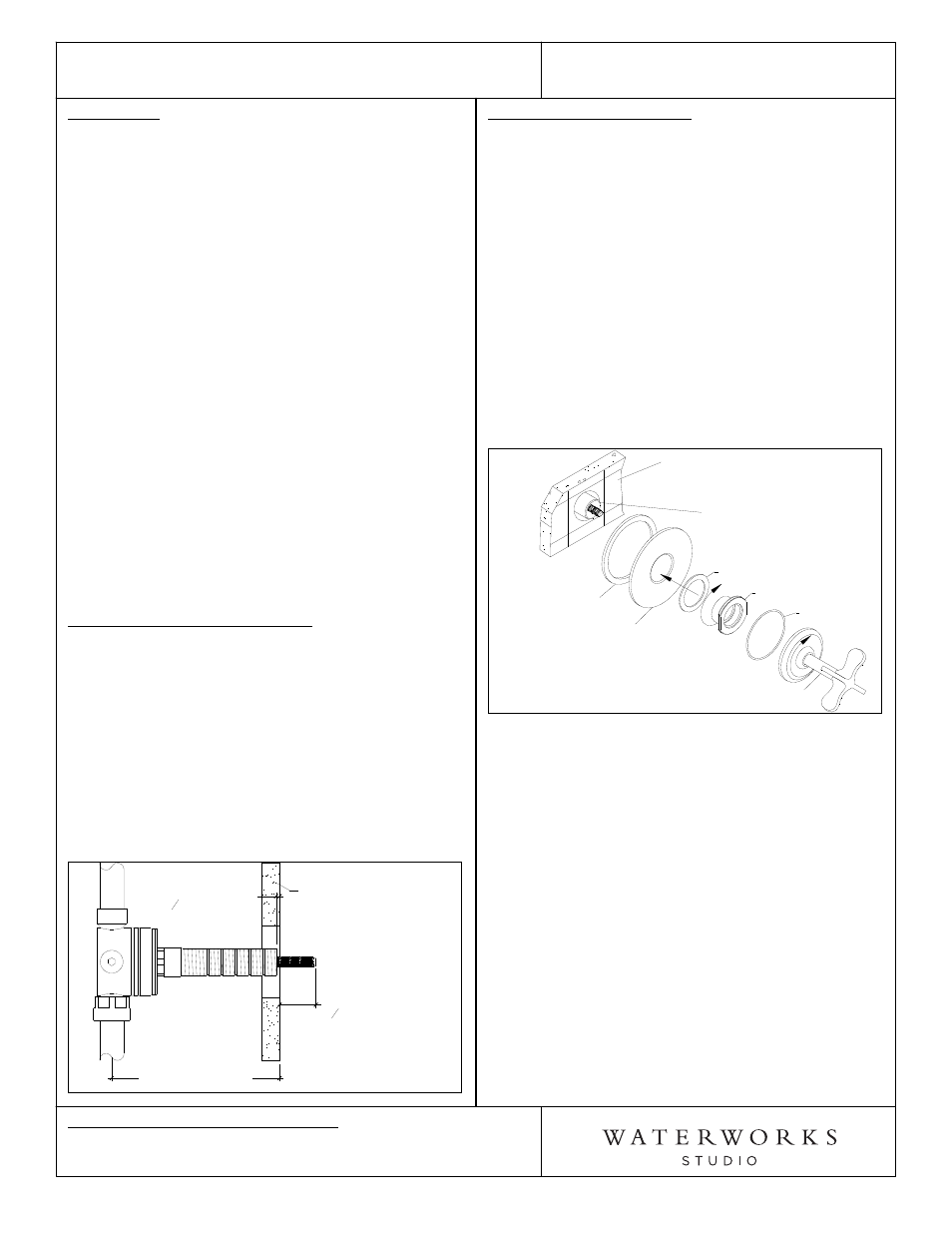

TRIM PLATE INSTALLATION:

¾ See Figure 2 for Steps 4-6.

4. After the proper cuts have been made, slide the

DIVERTER PLATE over the modified diverter valve

components and hold to finished wall, making sure

FOAM GASKET is behind it.

5. While holding DIVERTER PLATE against the finished

wall, thread & tighten TRIM ADAPTER onto the

THREADED TUBE, making sure the RED FIBER

WASHER is between DIVERTER PLATE and TRIM

ADAPTER.

6. With the correct orientation, thread the HANDLE

ASSEMBLY onto the TRIM CONNECTOR making

sure the O-RING is between the escutcheon and

DIVERTER PLATE. Note: The escutcheon is used to

tighten handle assembly.

Figure 2

FINISHED WALL

DIVERTER PLATE

FOAM GASKET

DIVERTER VALVE

THREADED TUBE

& CARTRIDGE STEM

[SOLD SEPARATELY]

RED FIBER WASHER

TRIM ADAPTER

O-RING

HANDLE ASSEMBLY

¾ If further assistance is required, please contact

Product Support at 1-800-927-2120 (8am-6pm EST).

- Ludlow Three Way Diverter Trim for Thermostatic System with Cross Handle Ludlow Three Way Diverter Trim for Pressure Balance System with Lever Handle Ludlow Three Way Diverter Trim for Pressure Balance System with Cross Handle Ludlow Two Way Diverter Trim for Thermostatic System with Lever Handle Ludlow Two Way Diverter Trim for Thermostatic System with Cross Handle Ludlow Two Way Diverter Trim for Pressure Balance System with Lever Handle Ludlow Two Way Diverter Trim for Pressure Balance System with Cross Handle