Installation guidelines – Waterworks Universal Round Pressure Balance Control Valve Trim with White Porcelain Lever Handles User Manual

Page 2

TROUBLESHOOTING CHART

Installation Guidelines

W A T E R W O R K S

Æ

Pressure Balance Shower & Tub/Shower Systems

These guidelines have been prepared for the professional contractor to aid in the installation of:

PRESSURE BALANCE SHOWER & TUB/SHOWER SYSTEMS

(BNSV90+GUSV80R)(WWSV96+GUSV80R)(WWSV94+GUSV80R)

All dimensions are based on original specifications and are subject to change and variation.

Please consult your Design Associate for current specifications.

PROBLEM

Valve will not flow water.

Valve leaks when shut off.

Temperature control handle is turned from

cold to hot (or hot to cold), and volume from

spout/head is not constant.

Valve delivers sufficient quantity of cold, but

little hot (or the reverse of this).

Temperature varies without moving the handle.

Valve delivery temperatures reduces gradually

during use; handle must be turned to a hotter

position to maintain constant temperature.

CAUSE

Hot and cold water not turned on.

Hot and cold washers are worn, or

there is foreign matter between

washers and seat surfaces.

Pressure balancing piston housed in

spindle assembly is blocked from free

movement by foreign matter.

Same as above.

Same as above.

Overdraw on hot water supply; i.e.

running out of hot water.

SOLUTION

Turn on both supplies.Valve will not operate unless

both hot and cold water pressure is turned on.

Replace hot and cold washers; inspect top surface

on hot and cold seals; replace if necessary.

With valve open halfway, remove handle and tap

spindle with plastic hammer. If problem is not solved,

remove spindle assembly completely and tap handle

end against solid object to free piston. Soaking in

household vinegar will also help free foreign matter.

Same as above.

Same as above.

Check hot water source.

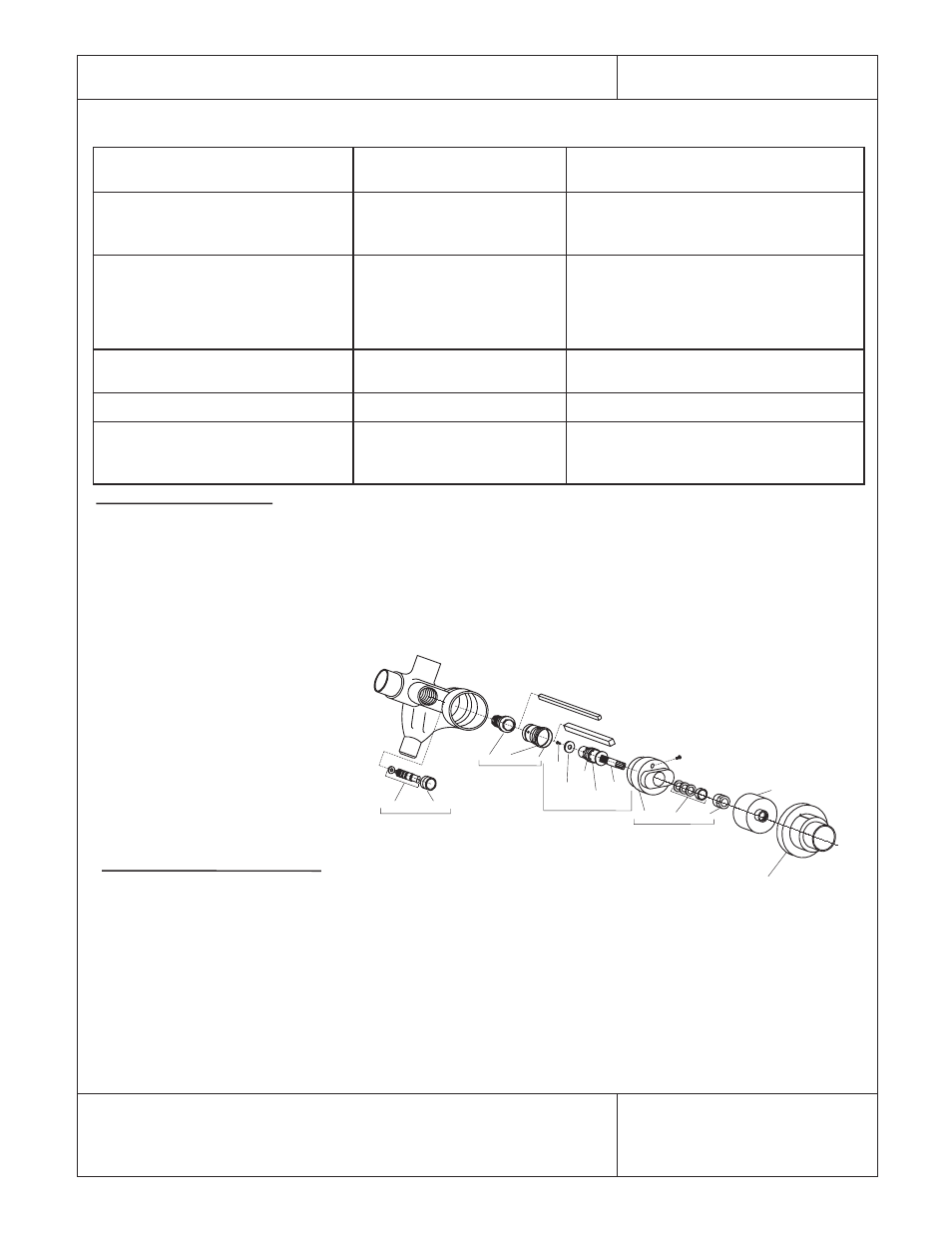

PARTS FOR GUSV80R:

T-26

to be discarded

before installing trim

T-19/20

T-34

T-11 T-16 T-17

T-12A

T-35A

T-35B

T-1 T-2 T-3

TA-4

T-52A T-55B

T-52

T-5

T-6

T-7

T-8

TA-10

T-A9

includes T-11

I

ndividual part numbers

T-1 Hot renewable seat

T-2 Cold seat O-ring

T-3 Cold renewable seat

T-5 Hot washer screw

T-6 Hot washer

T-7 Cold washer retainer

T-8 Cold washer

TA-10 Flow control spindle

T-11 Cap gasket

T-12A Cap assembly

T-16 Packing, O-ring and washer

T-17 Packing nut

T-19/20 Dome cover and lock nut

T-26 Plaster shield

T-34 Limit stop with O-ring

T-35A Hot seat removal tool

T-35B Cold seat removal tool

T-52A Stop spindle assembly/

escutcheon screw retainer

T-55B Stop plaster shield

T-55C Stop plaster shield removal tool

Composite part numbers

T-52 Stop spindle assembly/

escutcheon screw retainer (T-52A):

Stop plaster shield (T-55B)

TA-4 Hot seat (T-1); Cold seat (T-3);

Cold seat O-ring (T-2)

TA-9 Hot washer screw (T-5);

Hot washer (T-6);

Cold washer retainer (T-7);

Cold washer (T-8);

Cap gasket (T-11)

TA-10 Spindle assembly

GUSV81R

GUSV81R

GUSV81R