Waterworks Amelie Thermostatic Control Valve Trim with Metal Lever Handle User Manual

Installation guidelines

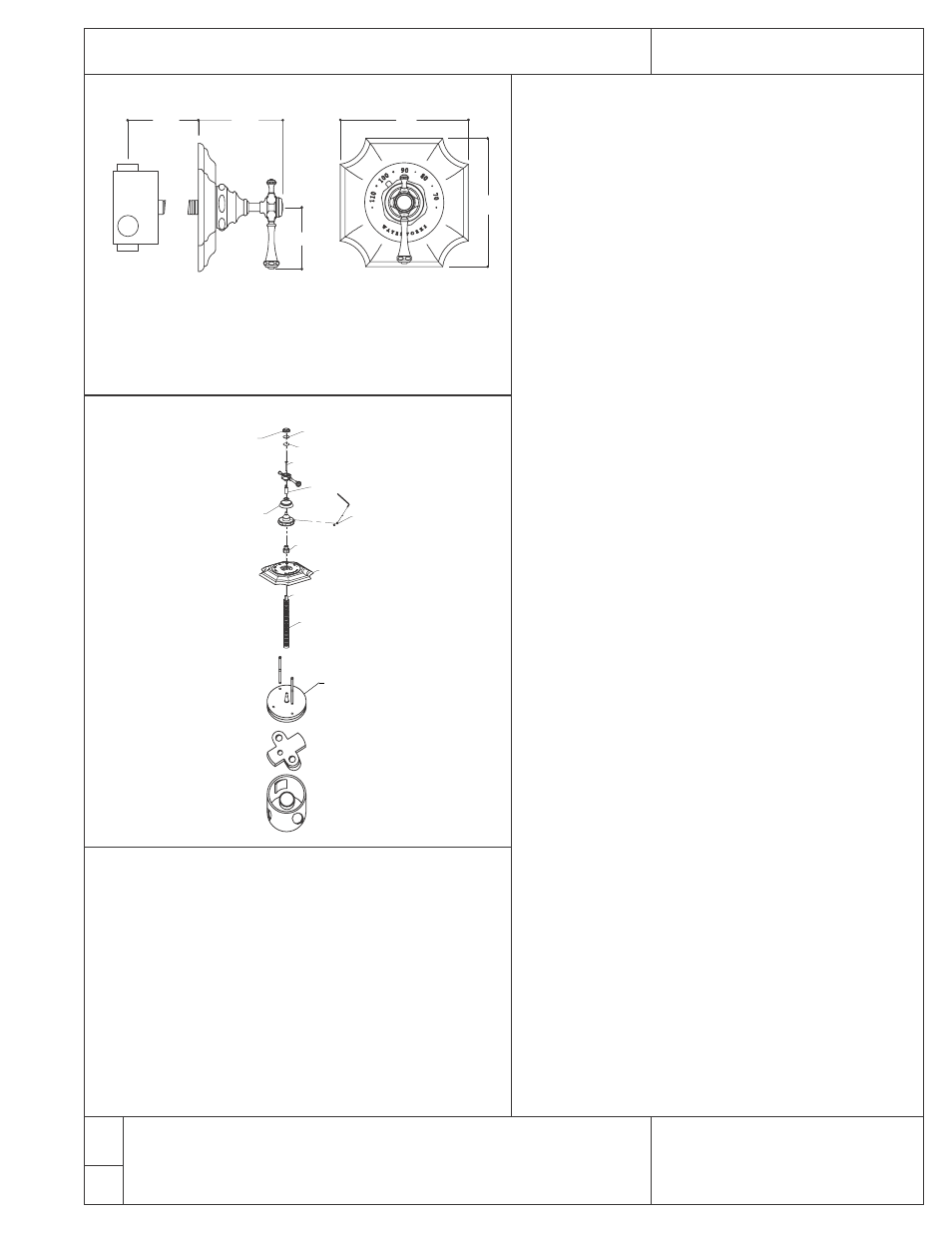

Amelie Thermostatic Shower Valve Trim With Lever Handle

4

/08

W A T E R W O R K S

These guidelines have been prepared for the professional contractor to aid in the installation of:

AMELIE THERMOSTATIC SHOWER VALVE TRIM WITH LEVER HANDLE

(GUSV37R & AMSV70)

All dimensions are based on original specifications and are subject to change and variation.

Please consult your Design Associate for current specifications.

Installation Guidelines

Figure 1

#5

#6

#7

#8

#9

Indice

ring

Indice

Rubber

gasket

Handle

screw

Stem

extension

Escutcheon

#4

1

GUSV37R (rough) + AMSV70 (trim)

7"

7"

4

5

/

8

"

2

1

/

2

"

3

3

/

8

"

3

/

4

"

female NPT

Notes:

• Ideal operating pressure is 40 - 50 psi

• Maximum static pressure is 125 psi

• Minimum static pressure is 25 psi

ROUGH-IN:

This device is a mixing valve controlling temperature only and requires at least one

wall valve (shut off) that also controls volume. The wall valve(s) must be ordered

separately.

➢ Check incoming water pressure; ideal operating pressure is 40-50 psi.

Maximum static pressure = 125 psi. / Minimum static pressure = 25 psi.

➢ BEFORE installation, remove the cartridge.

➢ IMPORTANT:Valve rough-in is 2

1

/

2

" from the centerline of supplies to face of

finished wall.

➢ Install hot on left and cold on right, according to the valve markings.

➢ Install wall valves (not included, must be ordered separately) with same

rough-in dimensions.

➢ BEFORE the cartridge is reinstalled, the valve should be tested for leaks

and lines should be flushed out. See “FLUSHING OUT SYSTEM”.

➢ Separate supply stops for hot and cold water lines are recommended and

should be accessible for service use.

FLUSHING OUT SYSTEM:

➢ Loosen the screws in face of valve in order to remove valve cover.

Cartridge is attached.

➢ Using the flat gasket provided to make a seal, flip the cover/cartridge over

and secure to the face of the valve using the screws provided.

➢ Fully open the hot and cold supply lines and flush out for several minutes.

Return the cartridge to its original position.

FINISH:

Please refer to the specification diagrams on the left side of this page.

➢ Use only a protected smooth-jawed, or strap wrench on any finished

surface.

➢ Attach the threaded sleeve(#5) to the rough body(#4). Slide the

escutcheon plate (#7) over the sleeve. Mark the threaded sleeve(#5) in

preparation of cutting

3

/

16

" beyond where it protrudes through the

escutcheon plate.

➢ Remove the plate and threaded sleeve so that the threaded sleeve(#5)

can be cut. Be sure not to cut the end with internal threads. File the cut

edge with care.

➢ Reattach the threaded sleeve(#5) and place the escutcheon plate(#7)

over it. (Note: 86°F is at 12 o'clock).

➢ Place cap(#8) onto threaded sleeve(#5).This should lock the escutcheon

plate tightly against the finished wall.

➢ Introduce the square tube(#6) into the cap(#8) and set it completely

onto the axel of the rough body(#4).

➢ Mark the square tube(#6) and cut it so it is recessed 1/8” from the end of

the cap(#8).

➢ Affix the handle trim adaptor(#10) to the cap(#8) using the set screw

(#9). Be sure to fully tighten.

➢ Push the stablizing ring(#12) into the escutcheon plate(#7).

SETTING THE HIGH TEMPERATURE LIMIT:

➢ IMPORTANT: The risk of scalding exists until the installer has properly set

the high temperature setting.

➢ Adjust the water to the maximum desired temperature.Temperature

adjustments are made by turning the fixing cap(#11).

➢ With the handle trim in the full hot position, snap onto the fixing

cap(#11).

➢ Temperature settings should be checked periodically to ensure the high

temperature limit is maintained.

➢ If further assistance is required, please contact Product Support at:

1-800-927-2120 (8am-7pm EST).