Glazing for butt glazed vertical, Minimizing condensati, Step 1) – EFCO 904 Series User Manual

Page 39: For butt glazed vertical, Fig. 40, Step 2), Gasket length = d.l.o. + 2, Fig. 41

PAGE 37

SECTION V A - GLAZING PROCEDURES

STEP 1)

the ends.

INTERSECTIONS.

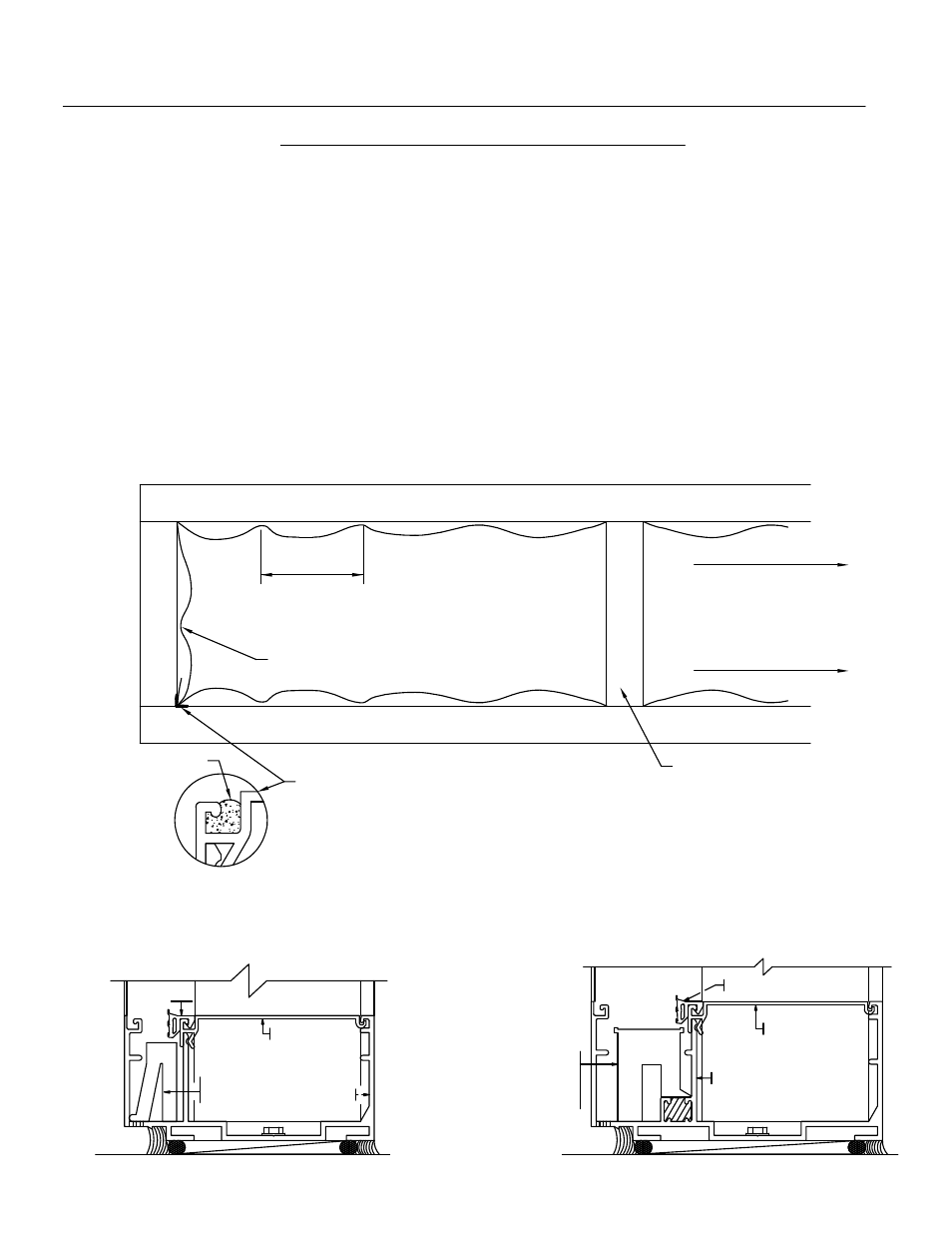

FOR BUTT GLAZED VERTICAL

from the exterior; install the interior gasket as follows.

the front of the butt glazed vertical. The glass will be installed

the middle, then to quarter points and work the "WAVES" toward

Start by pushing the gasket in place at the ends. Move to

The jamb gasket will run between. The gasket will run across

Glazing gasket (W164) will be continuous in the head / sill cans.

TO ITS ORIGINAL FORM, CREATING GAPS AT THE GASKET

DO NOT STRETCH THE GASKET OR IT WILL RETURN

GASKET RUNS TO JAMB

[FIG. 40]

SILL

VERTICAL

BUTT GLAZED

GASKET RUNS TO JAMB

9485

HN33 - 902

HN34 - 904

W164

9484

CDB 9/2009

HEAD

VARIES

8" - 12"

JAMB

RUN THRU.

JAMB GASKET TO

SEALANT

9479

9485

W164

STEP 2)

HNA1 - 901

HNA2 - 903

pockets. See Fig. 41 below.

Install setting block assemblies at 1/4 points in the sill can glazing

GASKET LENGTH = D.L.O. + 2%

BEFORE THE GASKETS ARE INSTALLED, SEAL 1"

VERTICALLY AND HORIZONTALLY IN THE GASKET

RACES WITH SILICONE TYPE SEALANT AT ALL

CORNERS. AFTER INSTALLATION SEAL THE ENDS

OF ALL GASKETS. SEALING RACES & GASKET END IS

REQUIRED AT THE INTERIOR OF THE SYSTEM.

EXTERIOR SEALANT AT RACE AND GASKETS ARE

OPTIONAL.

FU08 @ 1G66

902 I-BAR CAN

[FIG. 41]

See Fig. 40 below.