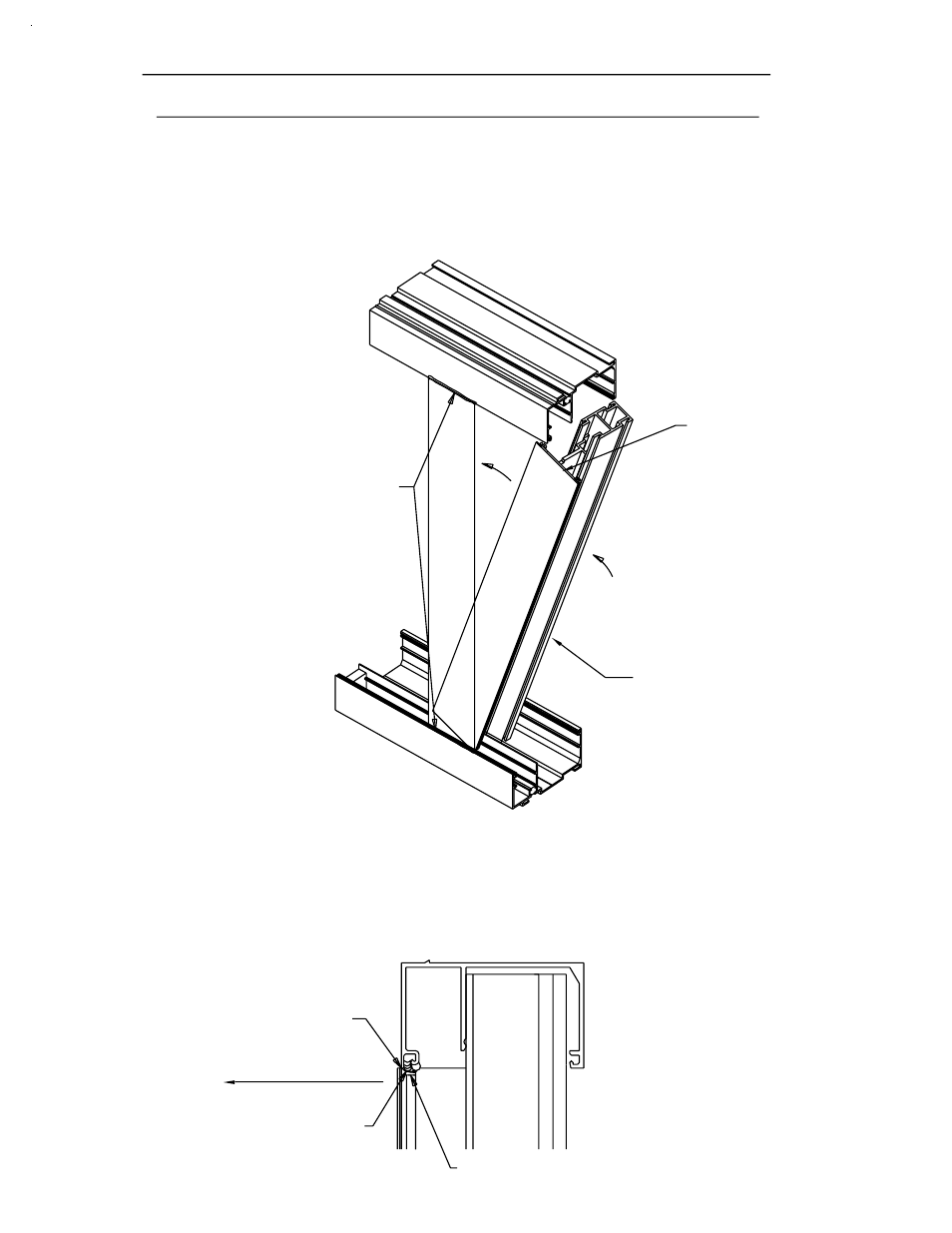

Fig. 29, Step 4) [fig. 28, Step 3) – EFCO 904 Series User Manual

Page 32: 2 pc. jamb and intermediate verticals

See Fig. 29 below.

THE FINISH ON THE HEAD CAN.

TAKE CARE NOT TO SCRATCH

UNTIL IT IS VERTICAL.

SEALANT IN GASKET

RECEIVER TRACK

HOLD MULLION OUT

NOTCH IN THE VERTICAL

MULLION FACE

[FIG. 29]

DPS 7/2001

Position the vertical mullion assembly angled above the sill can at

the back portion of the head can. The notch in the face portion

of the vertical will allow clearance around the glazing leg at the head.

Swing the captured mullion assembly up, letting the mullion back enter

STEP 4)

[FIG. 28]

the glazing gasket receiver track

Apply a butyl type sealant to

of the vertical mullion location.

at the top and bottom

SWING UP

SECTION IV B - INSTALLATION

vertical set into the back portion of the sill can.

approximately the vertical location. Let the back portion of the

STEP 3)

See Fig. 28 below.

2 pc. JAMB AND INTERMEDIATE VERTICALS

(CONT.)

PAGE 30

NOTE THAT THE

FACE PORTION IS

SHORTER THAN THE

BACK PORTION.

VERTICAL

INTERMEDIATE