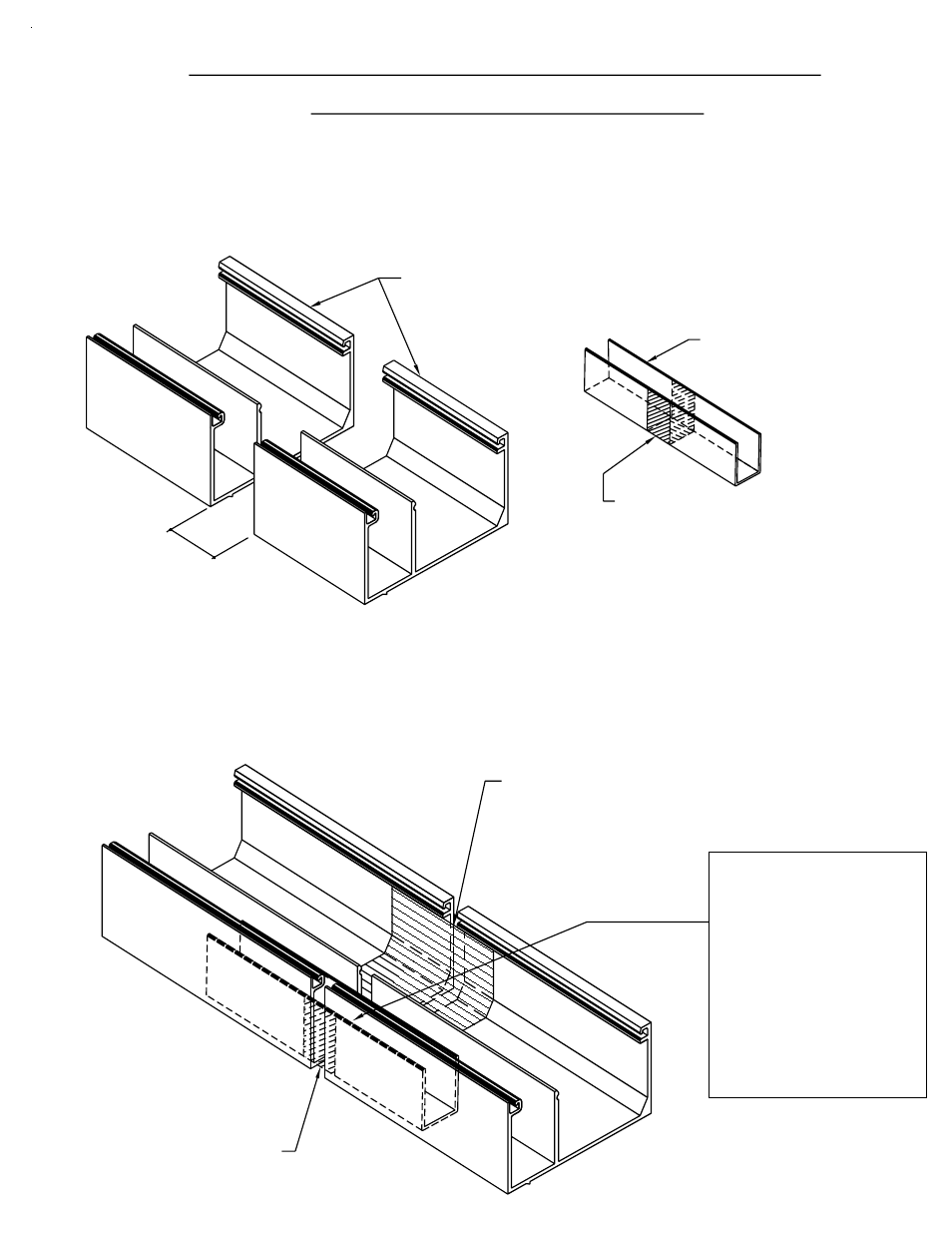

Head & sill can splice, Intermediate horizont, Head and sill can splice – EFCO 904 Series User Manual

Page 28: Step 2), Fig. 21, Step 1), Fig. 22

Slide the splice sleeve into the glazing pocket and center the sleeve

over the splice joint. See Fig. 22 below.

HEAD AND SILL CAN SPLICE

The main purpose of this operation is to ensure a water tight

seal between the two lengths of the sill can and prevent water from

entering the interior of the building. See Fig. 21 below.

To ensure proper adhesion of sealant to all parts, clean the sill cans

at the splice area and the splice sleeve with "MEK" to remove all oils.

SPLICE JOINT

CENTERED ON THE

BOND BREAKER TAPE

SPLICE SLEEVE WITH

STEP 2)

JOINT

SPLICE

[FIG. 21]

1/2"

STEP 1)

SECTION IV A - INSTALLATION

SILL CAN

902 - 9484 / K377

904 - 9477 / K379

904 - 8716 / K375

902 - 9845 / K375

904 - 9468 / K379

903 - 9476 / K378

CLV 7/2001

[FIG. 22]

901 - 9479 / K376

AROUND THE SPLICE SLEEVE

BREAKER TAPE WRAPPED

AT THE CENTER AND USED AS

A CAULK BACKER.

WM01 - 1" WIDE BOND

CAN # / SPLICE #

THE SPLICE SLEEVE

AT THE CENTER.

TAPE WRAPPED AROUND

BOND BREAKER

1" WIDE

SPLICE SLEEVE

PAGE 26

902 - 1G66 / K917