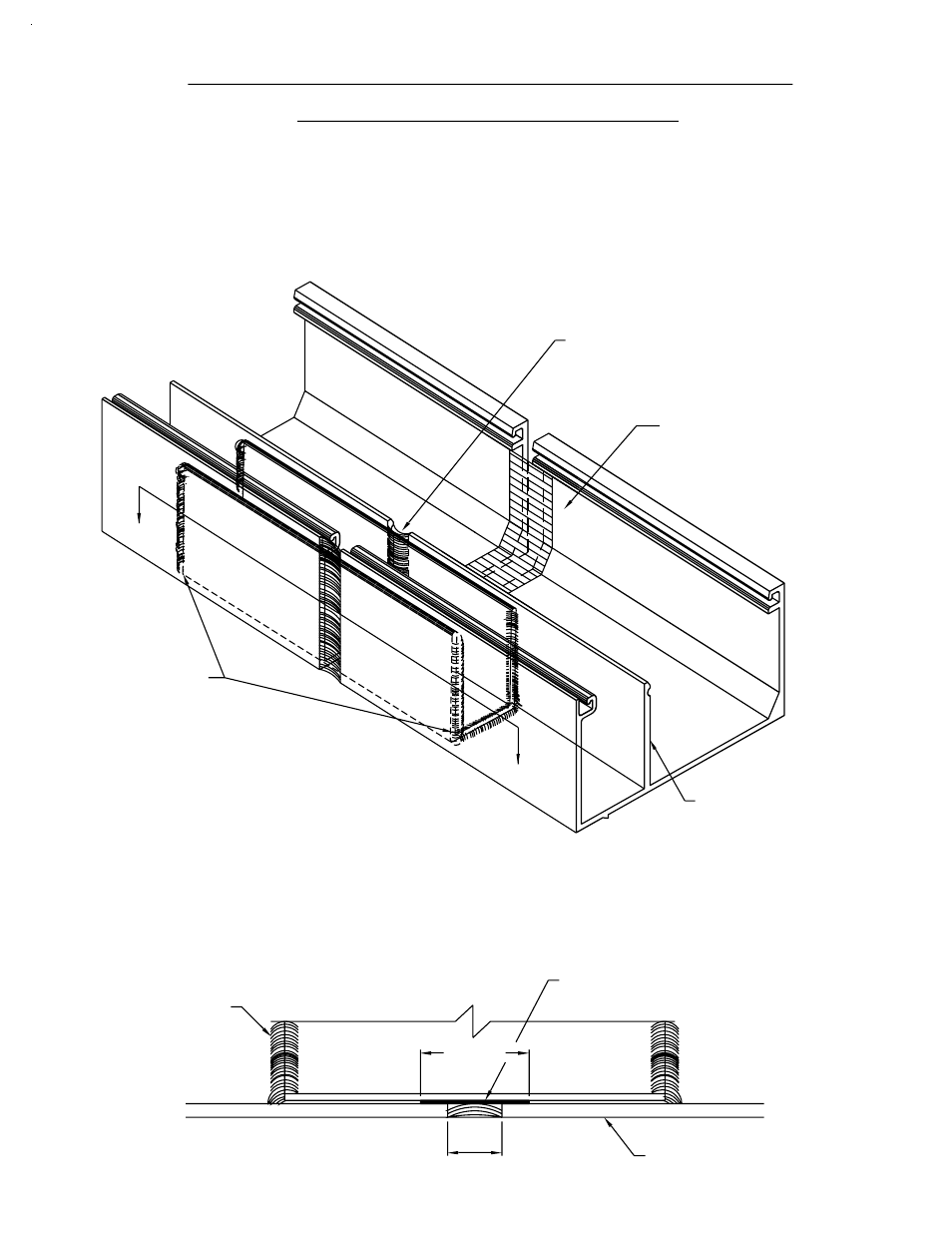

Step 5) step 4), Head and sill can splice, Step 3) – EFCO 904 Series User Manual

Page 29: Fig. 23

SECTION "A-A"

the seal to the splice sleeve and the two can members.

Apply sealant to the center vertical leg of the can, marrying

splice joint gap, and tool sealant smooth.

Proceed to the exterior face. Apply sealant to the exterior

OVER ENDS

TOOL SEALANT

STEP 5)

STEP 4)

BOTH SURFACES.

TOOL SEALANT

TO ADHERE TO

[FIG. 23]

1.000

SILL CAN

JDA 2/14/02

BOND BREAKER TAPE

"A"

LEG OF SILL CAN

CENTER VERTICAL

HEAD AND SILL CAN SPLICE

SECTION IV A - INSTALLATION

Apply a 1/4" bead of sealant over the ends of the splice sleeve.

Then tool the sealant across the edges of the sleeve and

onto the glazing pocket cavity surface. Be sure to work out any

air gaps that might occur. See Fig. 23 below.

"A"

STEP 3)

ACROSS THE GAP TO

APPLY SEALANT

ADHERE TO THE SILL CAN

AND THE SPLICE SLEEVE.

WM01 - 1" WIDE BOND

A CAULK BACKER.

AROUND THE SPLICE SLEEVE

BREAKER TAPE WRAPPED

AT THE CENTER AND USED AS

PAGE 27

(cont.)

Quick Set

1/2"