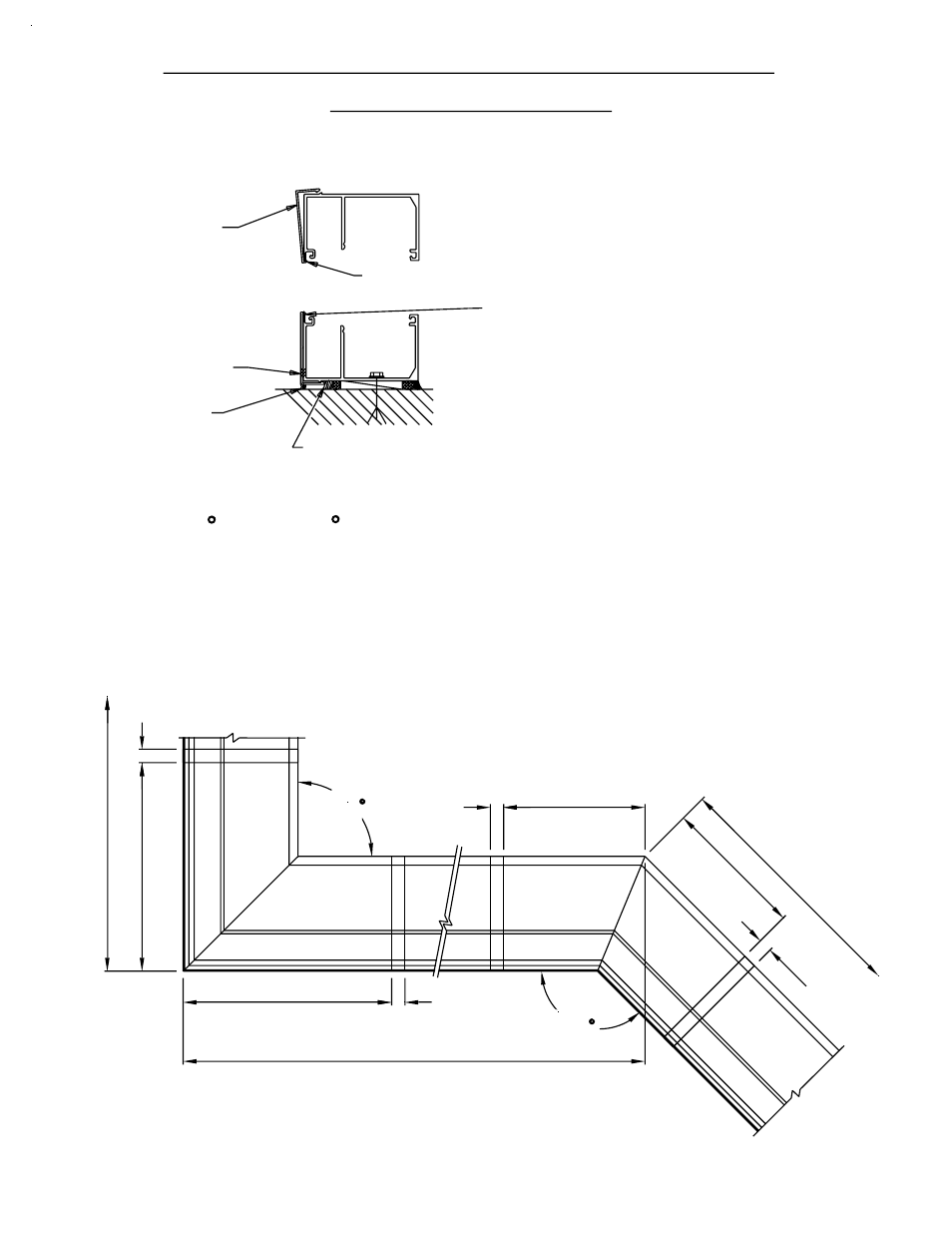

Head and sill can, Glazed mullion systems includes captured and butt, Fig. 4 – EFCO 904 Series User Manual

Page 16: See fig. 4 below, Recommended to reduce expansion at the miter joint, Fig. 3

FRAME DIM.

[FIG. 4]

FRAME DIM.

12"

1/2"

135

1/2"

DPS 7/2001

EXPANSION.

OUT OF POSITION WITH THERMAL

PREVENT COVER FROM WALKING

CRIMP THIS LEG SLIGHTLY TO

This includes 2 color covers installed prior to anchoring.

Head and sill cans are mitered for inside or outside corners.

STEP 4) 90 AND 135 CORNER FABRICATION

NOTE: An expansion/splice joint located 12" from the miter joint is

TAP LIGHTLY

TO SNAP IN PLACE

THRU COVER AND SILL

DRILL 1/4" DIA. WEEP HOLES

OPTIONAL SEAL

(LEAVE 1/4" SPACE

See Fig. 4 below.

AT WEEP HOLES)

recommended to reduce expansion at the miter joint.

1/2"

12"

90

1/2"

12"

HOOK COVER OVER LEG

BEHIND COVER LEG.

LOCATE PRIMARY SEAL

[FIG. 3]

12"

FRAME DIM.

(CONT.)

PAGE 14

HEAD AND SILL CAN

SECTION III C - FABRICATION

GLAZED MULLION SYSTEMS

INCLUDES CAPTURED AND BUTT

TOP VIEW OF THE SILL CAN AT

90˚ OUTSIDE AND 135˚ INSIDE CORNERS.